Method for preparing beta-SiAlON multiphase material by using ceramic polishing waste residue and coal gangue

A technology of ceramic polishing waste and coal gangue, which is applied to ceramic products, applications, household appliances, etc., can solve the problems of water and soil pollution, and β-SiAlON composite materials that have not yet been retrieved, so as to achieve increased added value and good social benefits And economic benefits, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] β-SiAlON materials were prepared by Shanxi coal gangue and Foshan ceramic polishing waste. The chemical composition of coal gangue and ceramic polishing waste was obtained by X-ray fluorescence spectroscopic analysis (XRF), as shown in Table 1.

[0059] Table 1: Chemical composition of coal gangue and ceramic polishing slag (mass percentage: %)

[0060] raw material SiO 2 Al 2 o 3 C CaO Fe 2 o 3 MgO K 2 o Coal gangue fine powder 50.50 43.16 13.64 1.49 1.57 0.8 0.8 Ceramic Polishing Slag 67.99 19.64 / 1.68 0.47 3.36 1.68

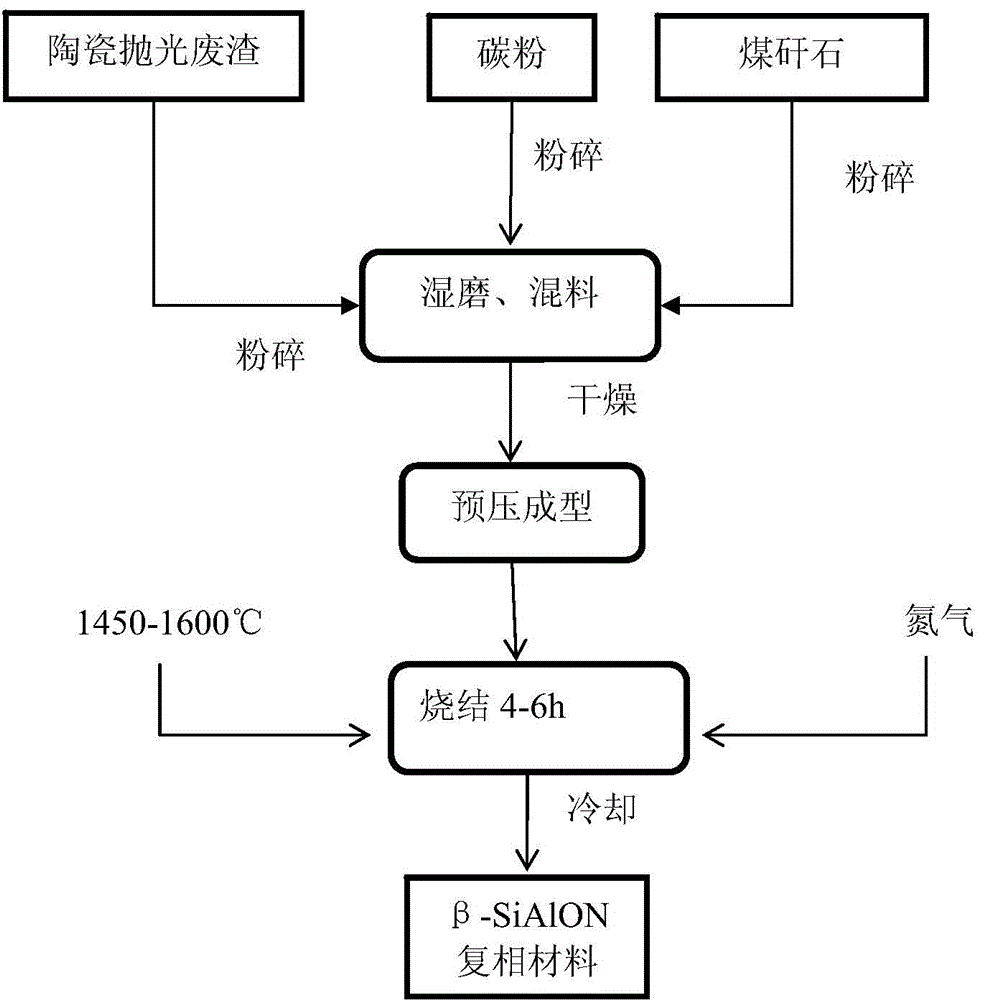

[0061] The z value of β-SiAlON is designed to be 3, that is, the molar ratio of Si and Al elements in the raw material is 1:1. The specific preparation method is as follows (see the specific flow chart figure 1 ):

[0062] 1. Pulverize ceramic polishing waste residue and coal gangue respectively, pass through a 45 μm sieve, and the particle size is as shown in Table 2:

[0063] Table 2: Part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com