Cu-doped Type-II core-shell structure white light quantum dot material and preparation method thereof

A technology of quantum dot material and core-shell structure, applied in the field of semiconductor nanomaterial preparation, can solve the problems of reducing the luminous efficiency and luminous stability of LEDs, the technology needs to be innovated and improved, and the fluorescence quantum efficiency is low, etc., and achieves strong chemical stability and Antioxidative ability, reduction of light reflection and scattering, effect of uniform spatial distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

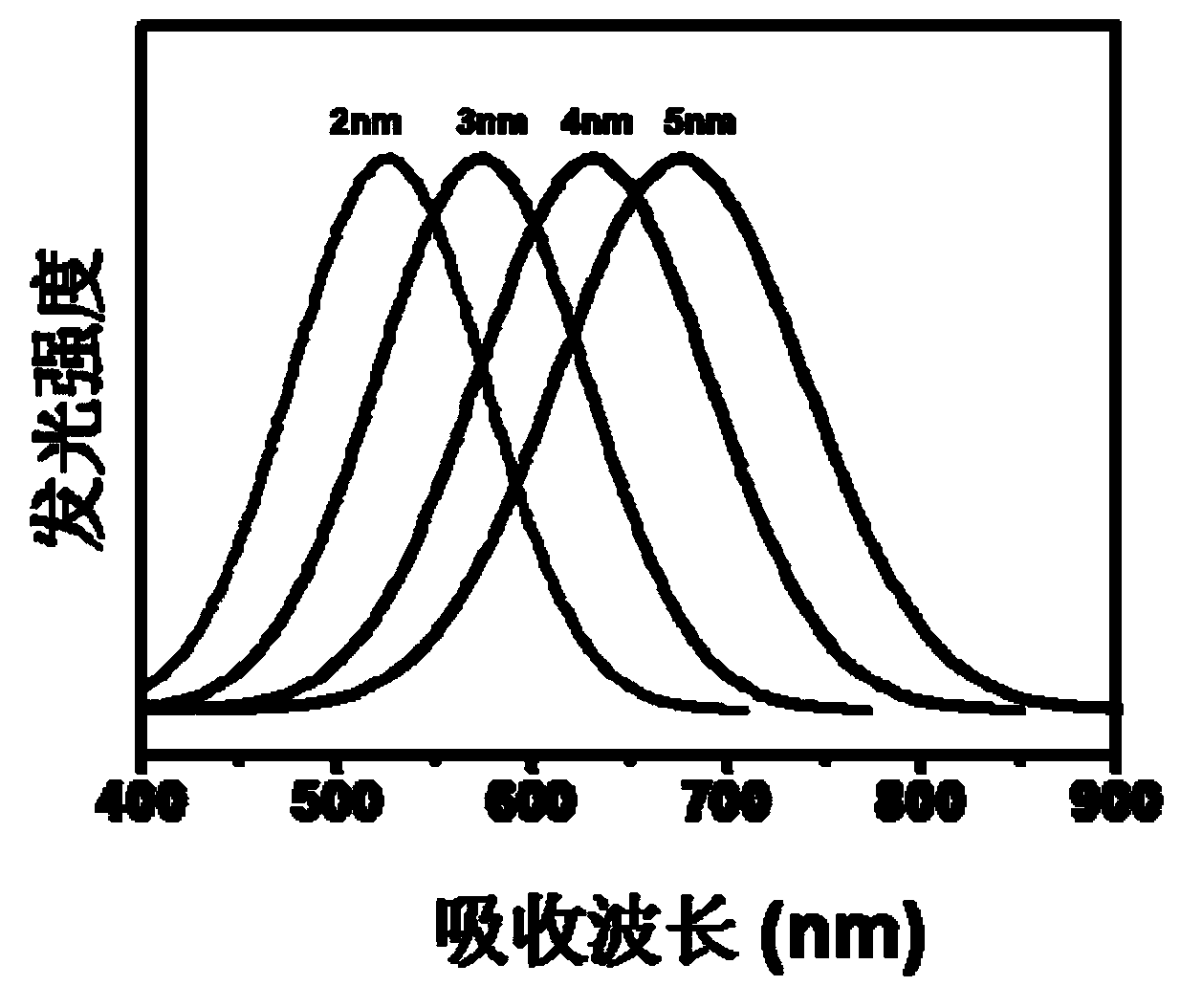

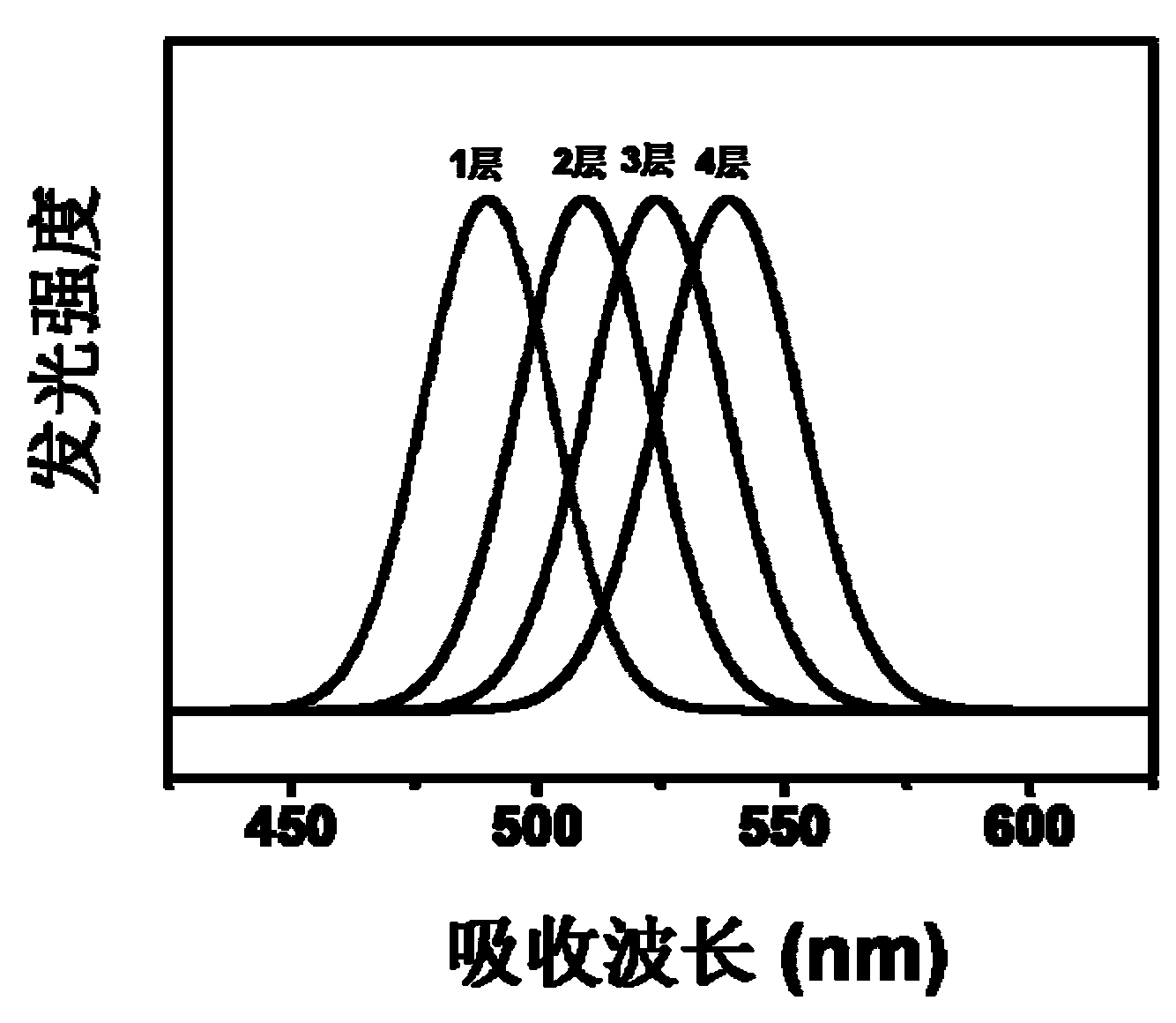

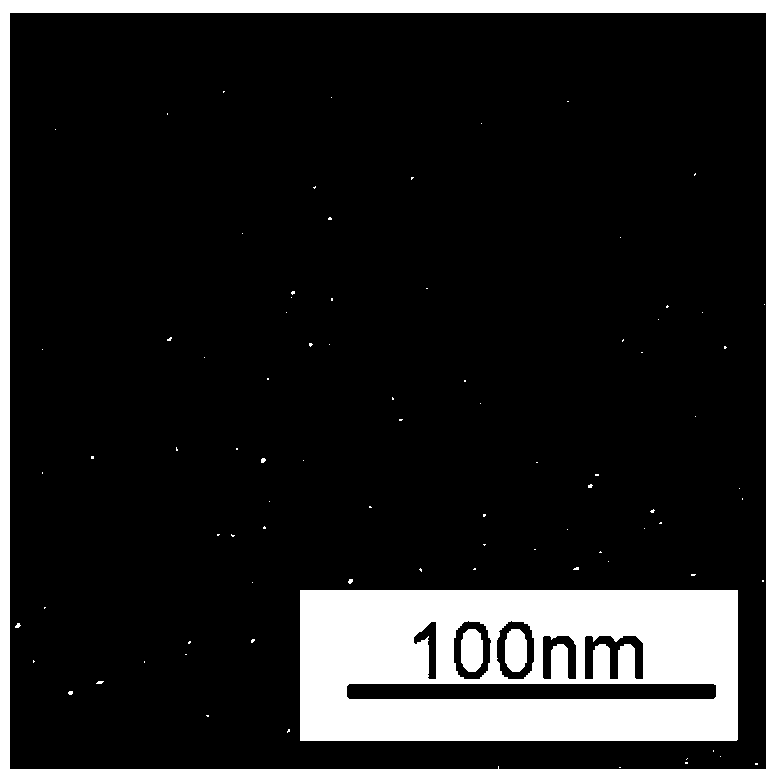

[0035] First, add 0.02mmol copper acetate, 0.2mmol cadmium acetate, 1mmol oleic acid, and 1mmol oleylamine to 5ml octadecene. The temperature is increased to 80°C, vacuum is applied, and then 1mmol dodecyl mercaptan is added; the temperature is increased under nitrogen protection To 120℃, inject 0.2ml of sulfur octadecene solution with a concentration of 1mol / L, keep it for 10 minutes and then cool to room temperature to obtain a 2nm Cu-doped CdS quantum dot core solution, and the amount of Cu doped is molar ratio Cu:Cd =10:100, the fluorescence quantum efficiency is 7%.

Embodiment 2

[0037] First, add 0.02mmol copper acetate, 0.2mmol cadmium acetate, 1mmol oleic acid, and 1mmol oleylamine to 5ml octadecene. The temperature is increased to 80°C, vacuum is applied, and then 1mmol dodecyl mercaptan is added; the temperature is increased under nitrogen protection At 150℃, inject 0.2ml of sulfur octadecene solution with a concentration of 1mol / L, keep it for 10 minutes and then cool to room temperature to obtain a 3nm Cu-doped CdS quantum dot core solution, and the amount of Cu doped is molar ratio Cu:Cd =10:100, the fluorescence quantum efficiency is 7%.

Embodiment 3

[0039] First, add 0.02mmol copper acetate, 0.2mmol cadmium acetate, 1mmol oleic acid, and 1mmol oleylamine to 5ml octadecene. The temperature is increased to 80°C, vacuum is applied, and then 1mmol dodecyl mercaptan is added; the temperature is increased under nitrogen protection At 180℃, inject 0.2ml of sulfur octadecene solution with a concentration of 1mol / L, keep it for 10 minutes and then cool to room temperature to obtain a 4nm Cu-doped CdS quantum dot core solution, and the amount of Cu doped is molar ratio Cu:Cd =10:100, the fluorescence quantum efficiency is 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com