Method for negative-pressure boiling extraction and preparation of low-acid ginkgo extract

A technology of ginkgo extract and negative pressure extraction, which is applied in the directions of medical raw materials, drug combinations, cardiovascular system diseases, etc. derived from Ginkgo biloba The problem of low ester content, etc., achieves the effect of simple process operation, shortened extraction time and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

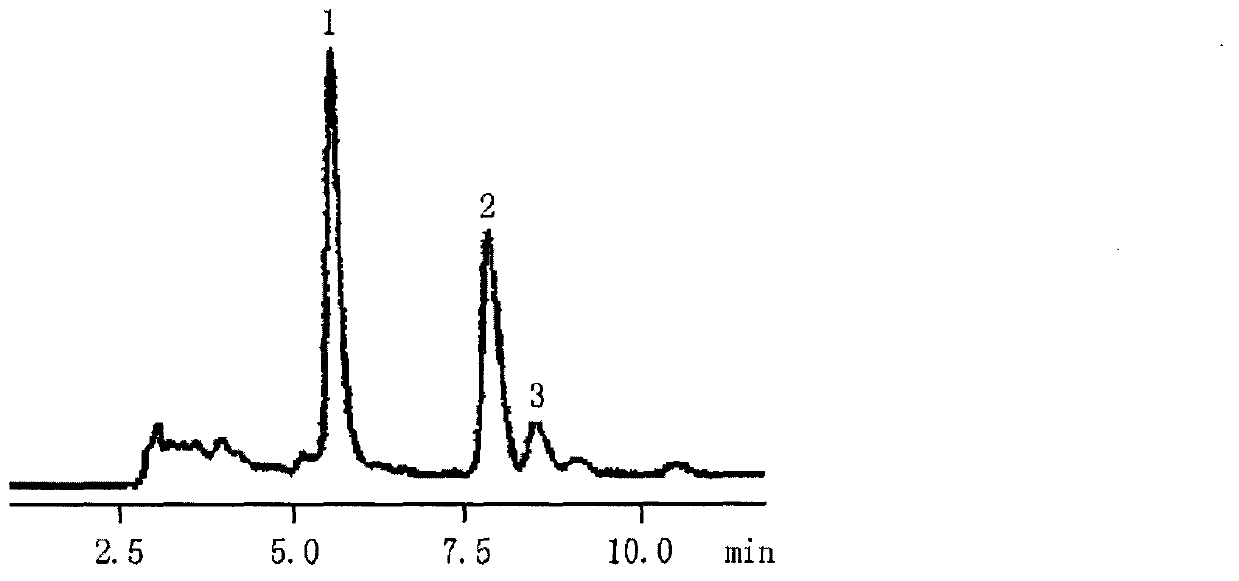

[0054] 1. HPLC analysis method of total flavonoids in Ginkgo biloba extract

[0055] Using UV detection method

[0056] (1) Chromatographic conditions: column C 18 ODS (Φ4.6mm×200mm, 5μm), mobile phase: methanol-water (containing 0.4% phosphoric acid) volume ratio 50:50, detection wavelength 360nm, flow rate 1ml / min.

[0057] (2) Standard curve drawing: Accurately weigh appropriate amounts of quercetin, kaempferol, and isorhamnetin reference substances respectively, place them in a 10mL volumetric flask, dissolve them with methanol and dilute to the mark, shake well, and make the concentrations respectively 0.854 , 0.562, 0.259mg / mL mixed reference substance solution; successively accurately measure the mixed reference substance solution 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, 0.40, 0.50mL in a 5mL volumetric flask, dilute to the mark with methanol, After shaking well, 10 μL samples were taken for chromatographic analysis. The equation of quercetin standard curve is y=51908x+63...

Embodiment 2

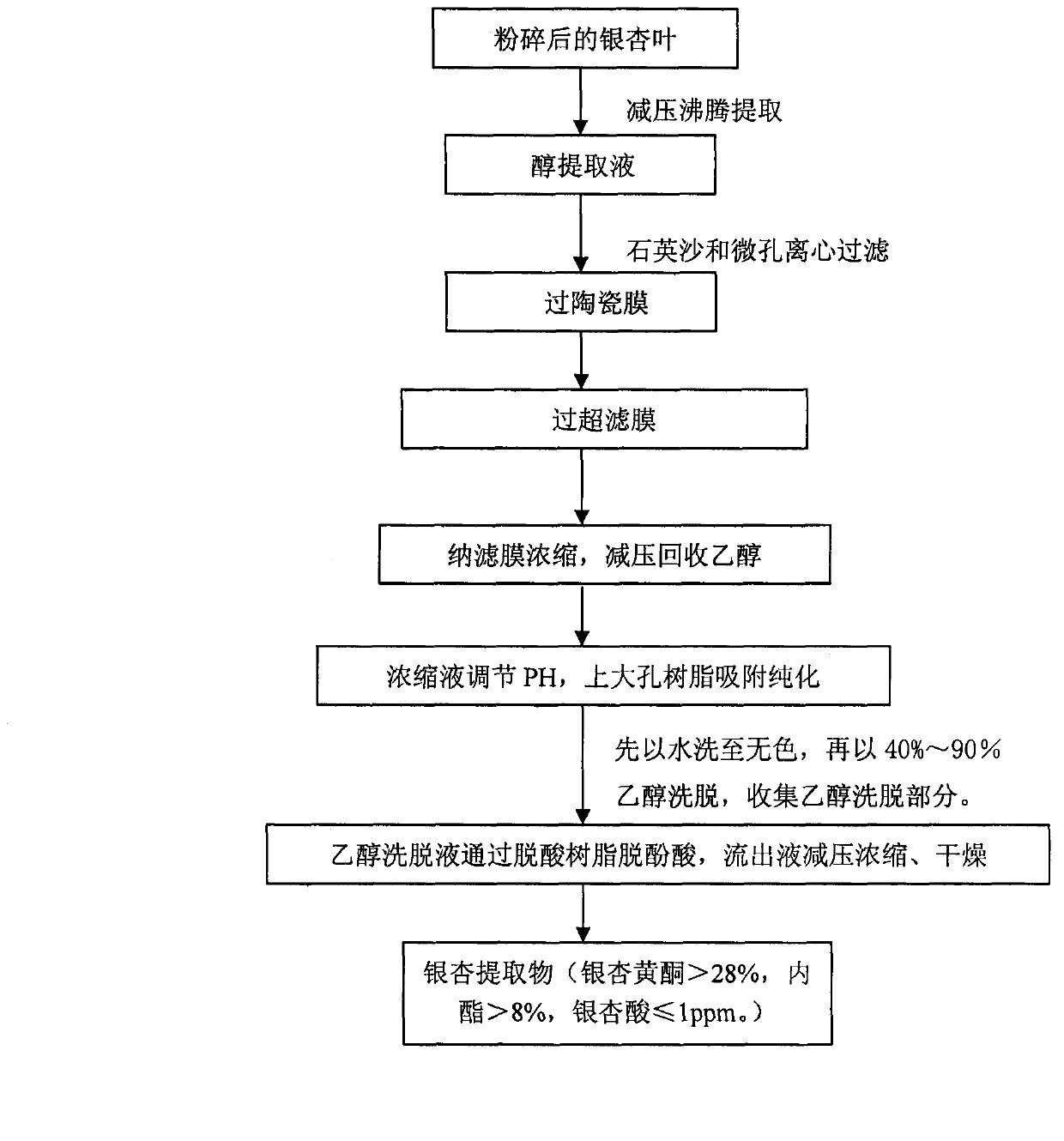

[0074] Negative pressure extraction and extract pretreatment

[0075] Ginkgo fresh leaves or ginkgo dry leaves are crushed to below 0.5 cm, and 40-80% ethanol is used as an extraction solvent, and the negative pressure boiling is extracted for 30-90 minutes, preferably 45-60 minutes, and the ratio of the extraction solvent to the ginkgo leaf powder is 1-30: 1. Preferably 5-15:1, extraction temperature is 20-70°C, preferably 40-60°C, extraction pressure is 0.01-0.09MPa, preferably 0.06-0.09MPa, extract 1-4 times, preferably 2-3 times, extract The solution is firstly filtered through quartz sand with a particle size of 100-300 mesh, and then microporous centrifugal filtration with a pore size of 1.0 μm to 1.5 μm and a centrifugal speed of 3000 to 6000 rpm; the extraction rate of total ginkgo flavonoids is greater than 90%, and the extraction rate of ginkgolides The extraction rate is greater than 80%.

[0076] The present invention has studied the influence of extraction pressu...

Embodiment 3

[0085] Membrane purification process

[0086] Pass the above filtrate through a ceramic membrane with a pore size of 0.1 μm to 0.8 μm, preferably a ceramic membrane with a pore size of 0.5 μm and an operating pressure of 0.15 to 0.3 MPa, and continue to pass the ceramic membrane permeate through an ultrafiltration membrane with a molecular weight cut-off of 5,000 to 50,000 , the preferred ultrafiltration membrane molecular mass cut-off is 10000, the ultrafiltration membrane permeate is concentrated with a nanofiltration membrane with a molecular mass cut-off of 100-300, the concentrated solution is decompressed to recover ethanol, and the pH value of the concentrated solution is adjusted with acid After 4 to 6, the upper column liquid is obtained.

[0087] The present invention selects 0.1 μ m, 0.2 μ m, 0.5 μ m, the ceramic membrane aperture of 0.8 μ m, investigates the impact of the membrane aperture on membrane flux, transfer rate and impurity removal rate of total flavonoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com