Monoalkyl phosphinate removal technology, product and application

A technology of alkyl phosphinate and mono-alkyl phosphinic acid, applied in application, removal process and product field of mono-alkyl phosphinate, can solve product purification, adverse environmental impact, unfavorable industrial production, etc. problems, to achieve the effect of improving the thermal stability level, strong practicability, and improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

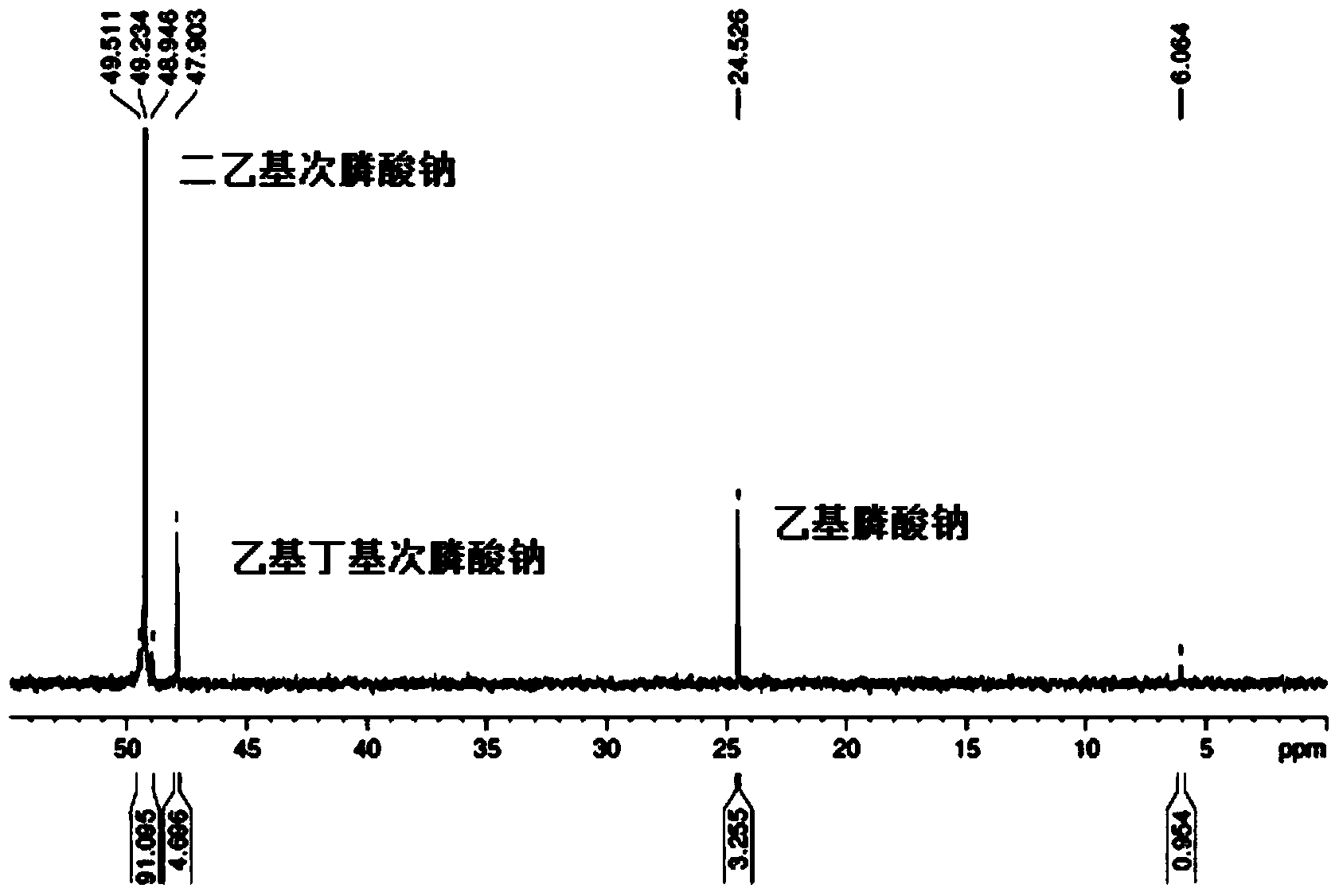

[0037] Get 30g of acetic acid mixture of sodium diethylphosphinate (0.0507 mol) and sodium monoethylphosphinate (total phosphorus molar percentage is about 3.6mole%), add dropwise molar amount P-H (monoethyl sodium phosphinate) of 150mol% sodium hypochlorite aqueous solution (active chlorine content is 5.2%), reacted for 10 minutes, measured the phosphorus spectrum of the solution, and the results showed that monoethyl sodium phosphinate had been completely converted into the known ethyl phosphonic acid sodium( figure 1). Remove acetic acid and water by distillation under reduced pressure, then configure it into an aqueous solution with a concentration of 6% by mass, heat it to 90°C with stirring, slowly drop it into an aqueous solution of aluminum sulfate with a concentration of 6% by mass, and stir for 0.5h to form The white solid was filtered, the precipitate was washed with 600ml of water, and dried at 130°C for 10h to obtain aluminum diethylphosphinate (87.9% yield). Af...

Embodiment 2

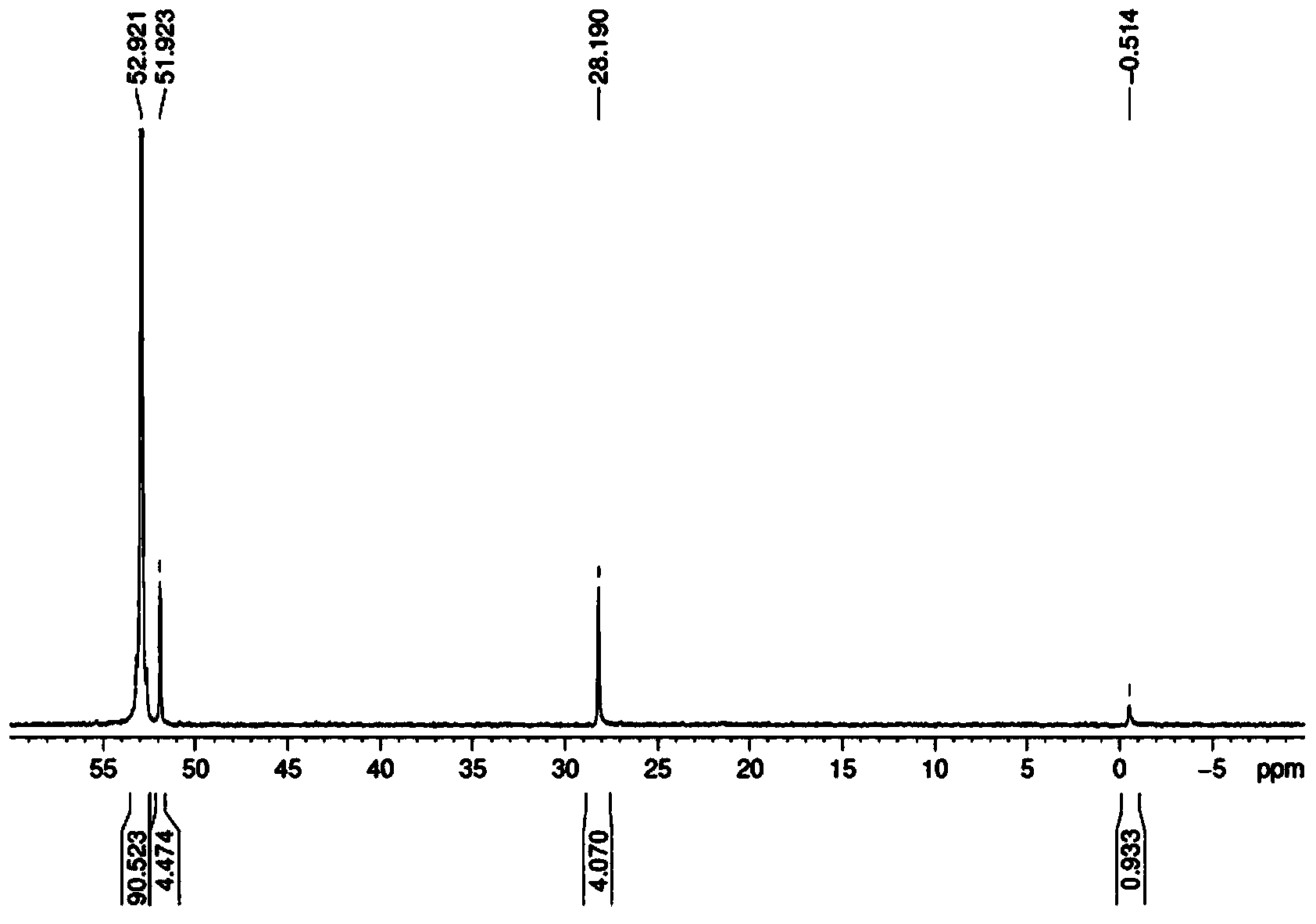

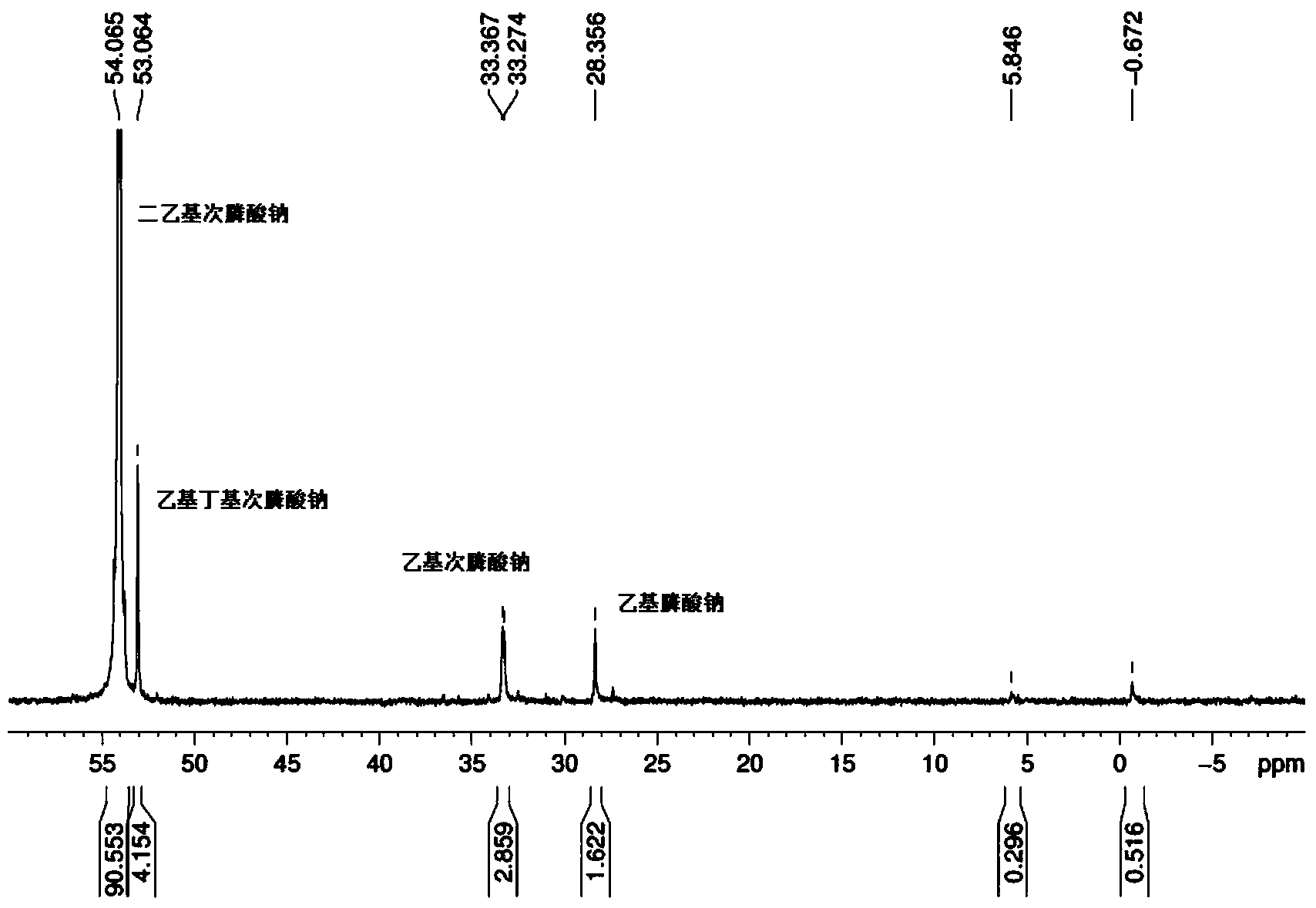

[0039] Get 31.7g of an acetic acid mixture of sodium diethylphosphinate (0.0536 mol) and sodium monoethylphosphinate (total phosphorus molar percentage is about 3.6mole%), distill under reduced pressure to remove acetic acid, and add dropwise a molar amount of P-H 150mol% sodium hypochlorite solution (active chlorine content is 5.2%), reacted for 10 minutes, and measured the phosphorus spectrum of the solution. The results showed that monoethyl sodium phosphinate had all been converted into known sodium ethyl phosphonate ( figure 2 ). Then configure it into an aqueous solution with a concentration of 6% by mass, stir and heat it to 90°C, slowly drop it into an aqueous solution of aluminum sulfate with a concentration of 6% by mass, stir and react for 0.5h, a white solid is formed, filter it, and use 500ml of water The precipitate was washed and dried at 130°C for 10 h to obtain aluminum diethylphosphinate (yield 73.4%). After the product was dissolved in sodium hydroxide, th...

Embodiment 3

[0043] Nylon 66 (containing 35% glass fiber) was dried in a vacuum oven at 110°C for 4 hours, and then 70 parts (all parts by weight unless otherwise specified) were mixed with 30 parts according to Example 1 or Example 1. The aluminum diethylphosphinate prepared by the method described in 2 was mixed, and banburyed in a Brabender torque rheometer at 270° C. for 3 minutes. After drying, process it with a flat vulcanizer at 290°C to obtain a flame-retardant polymer molded product, and then use a universal sampler to cut it into a sample with a size of 100mm×13mm×3.2mm, according to the GB / T2408-2008 standard at the AG5100B level -Tested on the vertical burning tester, the result shows that it reaches the UL94 combustion level V-0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com