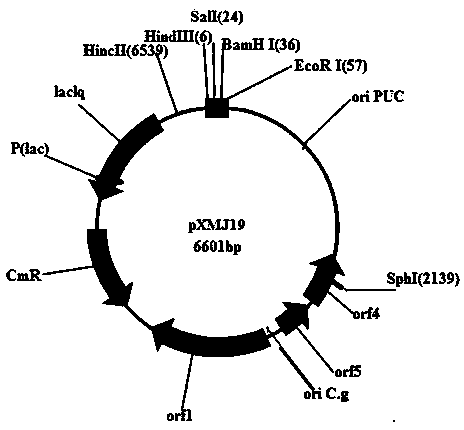

Conversion method for introducing shuttle plasmids into brevibacterium flavum (or corynebacterium glutamicum)

A technology of Corynebacterium glutamicum and Brevibacterium flavum, applied in the field of wild type and auxotrophic type, can solve the problems of expensive medium raw materials and low transformation efficiency, and achieve the effects of clear thinking, good transformation effect and broad prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of LB solid medium (pH 7.2): Mix 10 g tryptone, 5 g yeast extract, 10 g sodium chloride, 15 g agar powder and double distilled water thoroughly and dilute to 1 L with double distilled water; 121 High temperature sterilization for 20 min.

[0028]Preparation method of 10×inorganic salt mother liquor (PH 7.0): Dissolve 10 g of ammonium sulfate, 60 g of dipotassium hydrogen phosphate, 10 g of trisodium citrate and 2 g of magnesium sulfate heptahydrate in double distilled water and dilute to 1 L, 121 High temperature sterilization at ℃ for 20 min.

[0029] Preparation method of 20% glucose solution: Dissolve 20g of glucose in double-distilled water to 100 ml, filter and sterilize through a 0.22um bacterial filter, and store in a refrigerator at 4°C.

[0030] The preparation method of 2% casein hydrolyzate solution: 2g of casein hydrolyzate was dissolved in double distilled water and the volume was adjusted to 100ml, and sterilized by filtration with ...

Embodiment 1

[0031] Example 1 Transformation method of shuttle plasmid into wild-type Corynebacterium glutamicum ATCC 13032

[0032] Preparation of growth medium and induction medium

[0033] The preparation method of growth medium (1L): mix 10×inorganic salt mother liquor, 20% glucose solution, 2% casein hydrolyzate solution and double distilled water to obtain growth medium GM I; the solvent of growth medium is double distilled Water, solutes and their concentrations are as follows: ammonium sulfate 2 g / L, dipotassium hydrogen phosphate 14.8 g / L, trisodium citrate 1.9 g / L, magnesium sulfate 0.098 g / L, glucose 5 g / L, casein hydrolyzate 0.2 g / L.

[0034] Preparation method of induction medium (1L): mix 10× inorganic salt stock solution, 0.5 ml 0.1M CaCl 2 , 1ml 25 mM MgCl 2 , 20% glucose solution and double distilled water were mixed to obtain the induction medium GM II; the solvent of the induction medium was double distilled water, and the solute and its concentration were as follows:...

Embodiment 2

[0042] Example 2 Transformation method for introducing shuttle plasmid into auxotrophic Brevibacterium flavum AN78

[0043] Preparation of Growth Medium GM I and Induction Medium GM II

[0044] The preparation method of growth medium (1 L) GMI: mix 10X inorganic salt mother liquor, 20% glucose solution, 2% casein hydrolyzate solution and double distilled water to obtain growth medium; the solvent of growth medium is double distilled Water, solutes and their concentrations are as follows: ammonium sulfate 2 g / L, dipotassium hydrogen phosphate 14.8 g / L, trisodium citrate 1.9 g / L, magnesium sulfate 0.098 g / L, glucose 5 g / L, casein hydrolyzate 0.2 g / L, 0.25% amino acid mixture (His, Met, Pro).

[0045] The preparation method of induction medium (1 L) GM II: mix 10×inorganic salt mother solution, 20% glucose solution and double distilled water to obtain induction medium; the solvent of growth medium is double distilled water, and the solute and its concentration are as follows : ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com