Carbon-based material, electrode catalyst, oxygen reduction electrode catalyst, gas diffusion electrode, aqueous solution electrolytic device, and production method for carbon-based material

An electrode catalyst, carbon-based technology, which is used in catalyst activation/preparation, chemical instruments and methods, solid electrolyte fuel cells, etc., can solve the problems of platinum rarity, unstable cost, and high cost, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0145] In a reactor, 3 g of graphite (Wako 40 mm), 138 mL of concentrated sulfuric acid, and 3.47 g of potassium nitrate were mixed to prepare a mixture liquid. Potassium permanganate was further slowly added thereto while the reactor was in an ice bath. Subsequently, the mixture liquid thus obtained was stirred at 40° C. for 30 minutes, and then 240 mL of ion-exchanged water was added thereto, followed by stirring and heating at 90° C. for 1 hour. After that, 600 mL of ion-exchanged water and 18 mL of 30% hydrogen peroxide solution were added to the reactor to complete the reaction. After that, the resulting mixture liquid was washed with hydrochloric acid and water, followed by dialysis to remove ions therefrom. Further, ultrasonic waves were applied to the obtained mixture liquid to separate graphene oxide.

[0146] The graphene oxide thus obtained was dried. Thereafter, to 200 mg of the dried graphene oxide were added a 0.1M aqueous solution of iron(III) chloride and a ...

Embodiment 2 and 3

[0149] In Example 2, the amount of an aqueous solution of 0.1 M iron(III) chloride was adjusted so that the percentage of Fe atoms to graphene was 17% by mass. In Example 3, the amount of an aqueous solution of 0.1 M iron(III) chloride was adjusted so that the percentage of Fe atoms to graphene was 30% by mass. Except for these, in the same manner as those of Example 1, and under the same conditions as those of Example 1, carbon-based materials according to Examples 2 and 3 were prepared.

reference example 1

[0155] In Reference Example 1, in the step of heating the sample containing graphene oxide, iron(III) chloride, and pentaethylenehexamine, the heating time was two hours. Other than that, in the same manner as those of Example 2, and under the same conditions as those of Example 2, a carbon-based material according to Reference Example 1 was prepared.

[0156] [Raman spectroscopy]

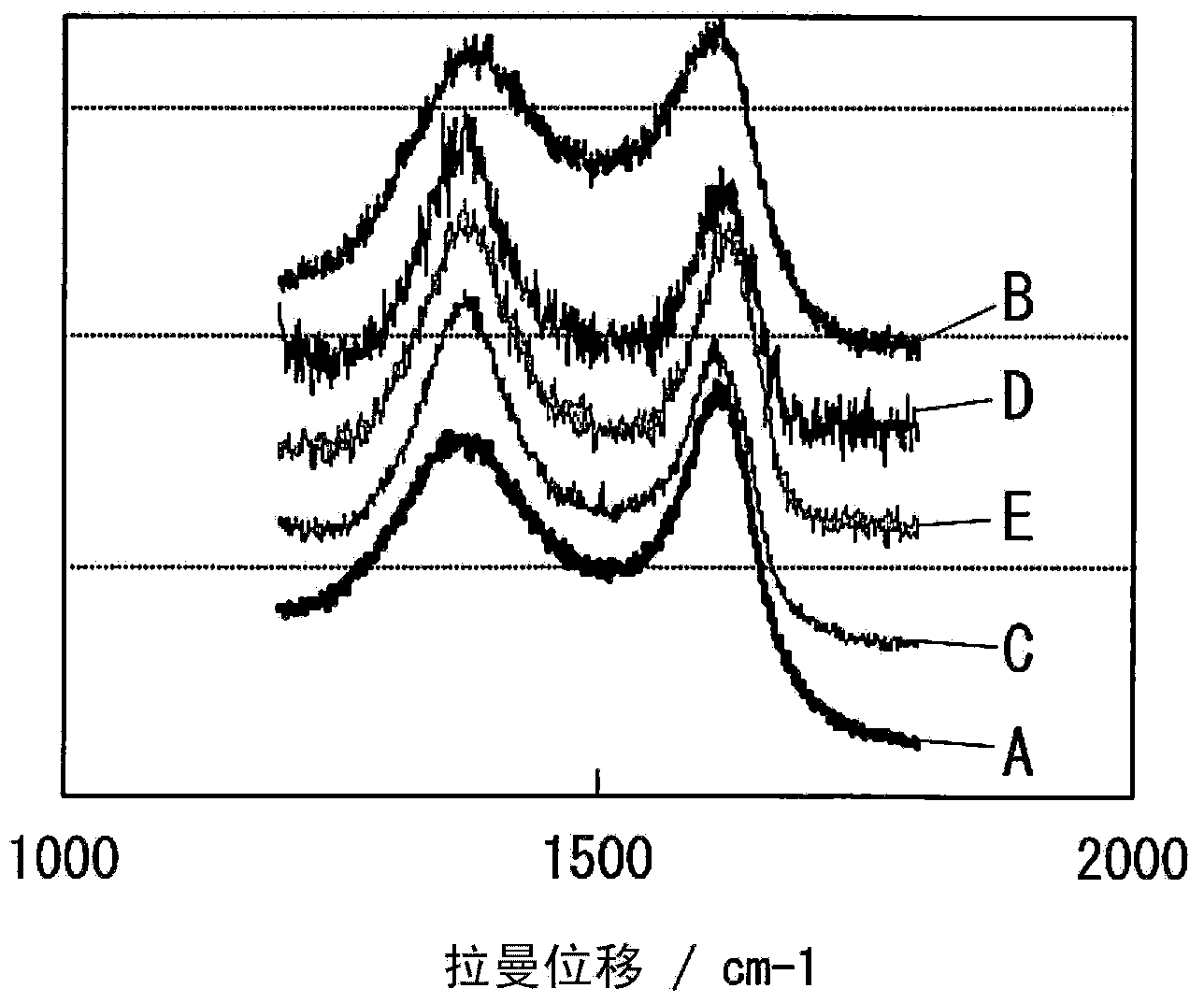

[0157] Graphite (Wako 40 mm), graphene oxide produced from this graphite in the aforementioned manner, and the carbon-based materials obtained in Example 2, Comparative Examples 1 and 2 were analyzed by Raman spectroscopy. image 3 The Raman spectrum thus obtained is shown. image 3 Among "A", "B", "C", "D", and "E" respectively represent graphite, graphene oxide, and the Raman spectra of the carbon-based materials obtained in Example 2 and Comparative Examples 1 and 2 .

[0158] as in image 3 As shown in , the results confirm that each Raman spectrum has 2 )-C(sp 2 ) bond G-band peak (right...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com