Sulfydryl-amidogen modified mesoporous silicon material as well as preparation method and application thereof

A technology of mesoporous silicon and amino groups, which is used in material excitation analysis, chemical instruments and methods, preparation of samples for testing, etc. Simple, use the effect of low column pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

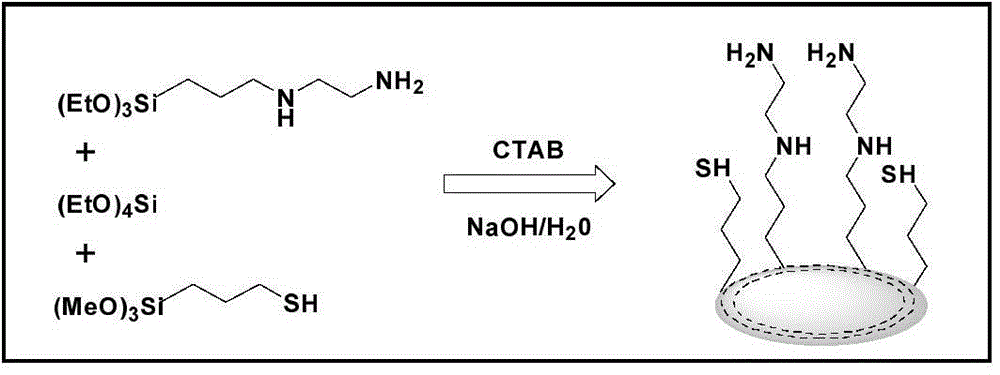

[0027] Example 1: Synthesis of mesoporous silicon materials co-modified with mercapto and amino groups according to the feed ratio of X=0.075

[0028] Raw materials: tetraethoxysilane (TEOS), mercaptopropyltrimethoxysilane (MPTMS), N-(β-aminoethyl)-γ-aminopropyltriethoxysilane (AAPTES), hexadecyl Trimethylammonium bromide (CTAB)

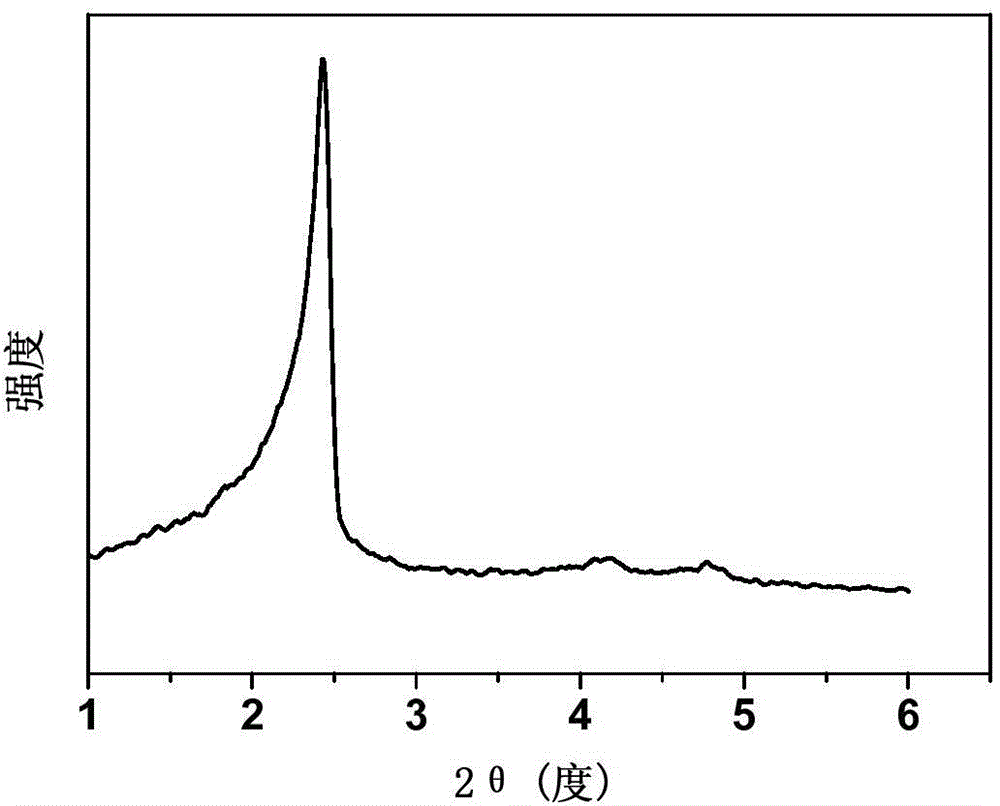

[0029] Specific steps: add 3.5mL NaOH (1M) solution to 120mL deionized water, then add 0.5gCTAB, stir at 80°C for 30 minutes, and the solution is a clear solution at this time. Take an appropriate amount of TEOS, MPTMS and AAPTES, so that the molar ratio of the feed is 0.85TEOS:0.075MPTMS:0.075AAPTES:0.11CTAB:0.28NaOH:532H 2 O, mix well, add to the above clear solution, and continue to stir at 80°C for 120 minutes. The resulting product was filtered, washed with water and ethanol in turn, and dried at room temperature. The dried solid particles were dispersed in a mixed solution of 0.5mL concentrated hydrochloric acid and 150mL ethanol, and stirre...

Embodiment 2

[0036] Taking two national standard materials as examples, the standard natural water body GSBZ50004-88 and the standard seawater GSB080230 were both purchased from the National Standard Material Center, and the content of inorganic arsenic in them was determined.

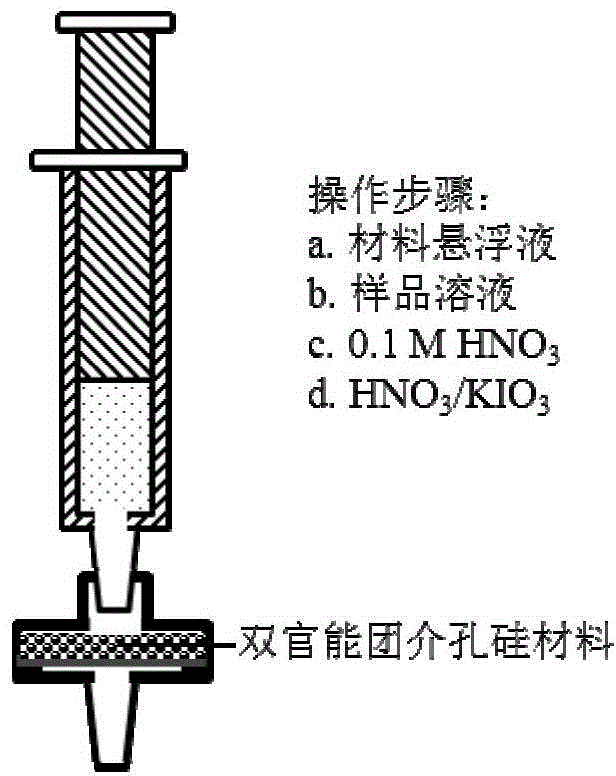

[0037] 1. Construction of the SPE Head

[0038] Weigh 40 mg of the material synthesized in Example 1 at a feed ratio of X=0.075 and disperse it in 2 mL of water, and then draw the suspension into a 5 mL syringe. Quickly inject 1mL of suspension into two 0.45μm syringe filters (inner diameter: 13mm) quickly and in turn, at this time, the water passes through the filter membrane, and the material is evenly deposited on the filter membrane, and each filter tip is fixed with 20mg of Material. Two extraction heads were made.

[0039] 2. Separation and enrichment of inorganic arsenic

[0040] First, adjust the pH of the sample to be tested to 4.0 with dilute nitric acid, take 10 mL of the sample solution, and -1 The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com