Polylactic acid-polyethylene glycol block copolymer-based magnetic microsphere preparation method

A technology of block copolymer and polyethylene glycol, which is applied in the field of preparation of magnetic microspheres, can solve the problems of weak magnetic response, low coating rate of magnetic polymer microspheres, uneven particle size distribution, etc., and achieve reduction Agglomeration, wide application range, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

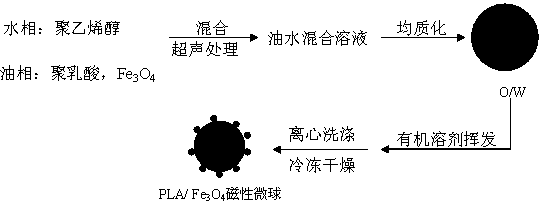

Method used

Image

Examples

Embodiment 1

[0024] 1. Modification of magnetic ferroferric oxide

[0025] (1) Ultrasonic disperse 1.0 g of ferric oxide in 100 mL of deionized water, then transfer the suspension of ferric oxide to a 250 mL three-necked flask, and use 10% hydrochloric acid solution (about 9-10 drops) Adjust the pH value of the ferroferric oxide suspension to 5.5-6.0, put it in a constant temperature water bath at 80°C while stirring (500r / min), add 0.15g sodium oleate, stir for 1-1.5h, and then add 0.05g of Polyethylene glycol, continue to stir and react for 1 hour, then cool to room temperature, then use 10% NaOH solution (about 5-6 drops) to adjust the pH of the solution to 7.

[0026] (2) Put the solution on a multi-purpose magnetic analyzer for rapid solid-liquid separation, wash it with deionized water and absolute ethanol 2 to 3 times, wash off excess oleic acid on the surface, filter it with suction, and dry it for later use.

[0027] 2. Preparation of oil-in-water emulsion

[0028] (1) Dissolve ...

Embodiment 2

[0034] One, the modification of magnetic ferroferric oxide: the same as above

[0035] 2. Preparation of oil-in-water emulsion

[0036] (1) Dissolve 1.0 g of polylactic acid-polyethylene glycol block copolymer (PLA-PEG-PLA) with a molecular weight of 10,000 in 15 mL of dichloromethane and acetone (V 丙酮 / V CH2Cl2 = 1:2), add 0.1g of modified ferric oxide, and ultrasonically disperse to obtain an oil phase;

[0037] (2) 1.0g of polyvinyl alcohol was heated at 95°C and stirred at 500r / min for 1 hour and dissolved in 100mL of deionized water to obtain the aqueous phase;

[0038] (3) Slowly add the organic phase to the water phase under the condition of stirring at room temperature. When the temperature is 60°C, use a high-speed dispersing homogenizer at 12000r / min to emulsify and disperse for 3-5min to obtain an oil-in-water (O / W) emulsion. The ratio of emulsified oil to water is 1:5-1:10.

[0039] 3. Emulsification solvent volatilization process: same as above

Embodiment 3

[0041] 1. Modification of magnetic ferroferric oxide: same as above

[0042] 2. Preparation of oil-in-water emulsion

[0043] (1) Dissolve 1.0 g of polylactic acid-polyethylene glycol block copolymer (PLA-PEG-PLA) with a molecular weight of 30,000 in 20 mL of dichloromethane and acetone (V 丙酮 / V CH2Cl2 = 1:4), add 0.15 g of modified ferric oxide, and ultrasonically disperse to obtain an oil phase;

[0044] (2) 1.0g of polyvinyl alcohol was heated at 95°C and stirred at 500r / min for 1 hour and dissolved in 100mL of deionized water to obtain the aqueous phase;

[0045] (3) Slowly add the organic phase to the water phase under the condition of stirring at room temperature. When the temperature is 60°C, use a high-speed dispersing homogenizer at 12000r / min to emulsify and disperse for 3-5min to obtain an oil-in-water (O / W) emulsion. The ratio of emulsified oil to water is 1:5-1:10.

[0046] 3. Emulsification solvent volatilization process: same as above

PUM

| Property | Measurement | Unit |

|---|---|---|

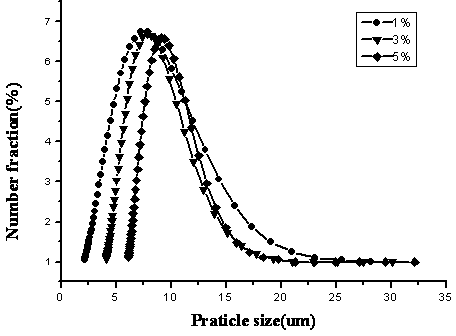

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com