A kind of wood-plastic foam composite material and preparation method thereof

A composite material, wood-plastic foaming technology, applied in the field of building materials, can solve the problems of limited performance improvement, high price and cost, application limitations, etc., to improve impact resistance and dispersion, improve compatibility, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

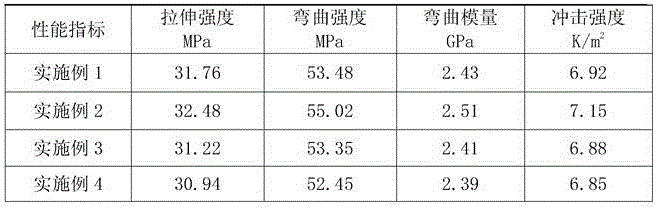

Examples

Embodiment 1

[0031] A wood-plastic foam composite material, in parts by weight, the composite material is made of the following raw materials: PVC resin 40kg, light calcium carbonate 30kg, wood powder 10kg, ACM anti-impact agent 3.5kg, HL-100 processing aid 3kg, liquid barium zinc composite stabilizer 3kg, PE wax 1.5kg, calcium stearate 0.5kg, foaming agent 0.8kg, epoxy soybean oil 1.5kg, baking soda 0.5kg and recycled PVC waste 15kg.

[0032] Wherein, the PVC resin is type 7 PVC resin; the particle size of the light calcium carbonate is 200 mesh; the wood powder has a water content≤5%, and the particle size is 60 mesh; The diameter is 80 mesh.

[0033] Weigh the raw materials according to the above formula ratio, and then prepare the wood-plastic foam composite material by the following steps:

[0034] 1) Put the weighed raw materials: 30kg of light calcium carbonate and 10kg of wood flour into a high-speed mixer for stirring. When the temperature rises to 75°C, keep the temperature and ...

Embodiment 2

[0042] A wood-plastic foam composite material, in parts by weight, the composite material is made of the following raw materials: PVC resin 50kg, light calcium carbonate 35kg, wood powder 10kg, ACM anti-impact agent 4kg, HL-100 processing aid 3kg , liquid barium-zinc composite stabilizer 3.5kg, PE wax 2kg, calcium stearate 0.6kg, foaming agent 1kg, epoxy soybean oil 2kg, baking soda 0.8kg and recycled PVC waste 15kg.

[0043] Wherein, the PVC resin is type 7 PVC resin; the particle size of the light calcium carbonate is 250 mesh; the wood powder has a water content≤5%, and the particle size is 70 mesh; The diameter is 90 mesh.

[0044] Weigh the raw materials according to the above formula ratio, and then prepare the wood-plastic foam composite material by the following steps:

[0045] 1) Put the weighed raw materials: 35kg of light calcium carbonate and 10kg of wood flour into a high-speed mixer for stirring. When the temperature rises to 80°C, keep the temperature and stir ...

Embodiment 3

[0053] A wood-plastic foam composite material, in parts by weight, the composite material is made of the following raw materials: PVC resin 45kg, light calcium carbonate 32kg, wood powder 15kg, ACM anti-impact agent 4kg, HL-100 processing aid 3.5 kg, liquid barium zinc composite stabilizer 3.5kg, PE wax 2.0kg, calcium stearate 0.6kg, foaming agent 1kg, epoxy soybean oil 1.8kg, baking soda 0.8kg and recycled PVC waste 20kg.

[0054] Wherein, the PVC resin is type 7 PVC resin; the particle size of the light calcium carbonate is 300 mesh; the wood powder has a water content≤5%, and the particle size is 80 mesh; The diameter is 100 mesh.

[0055] Weigh the raw materials according to the above formula ratio, and then prepare the wood-plastic foam composite material by the following steps:

[0056] 1) Put the weighed raw materials: 32kg of light calcium carbonate and 15kg of wood powder into a high-speed mixer for stirring. When the temperature rises to 85°C, keep the temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com