Multiple modified ultrafine non-metal powder partially replacing titanium dioxide powder, and preparation method thereof

A technology of non-metallic powder and titanium dioxide is applied in the field of multi-modified ultra-fine non-metallic powder that partially replaces titanium dioxide and its preparation. Overcome the tendency of agglomeration, good compatibility, improve the effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

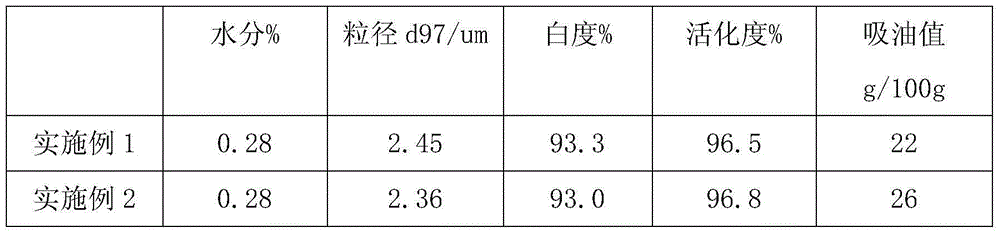

Examples

Embodiment 1

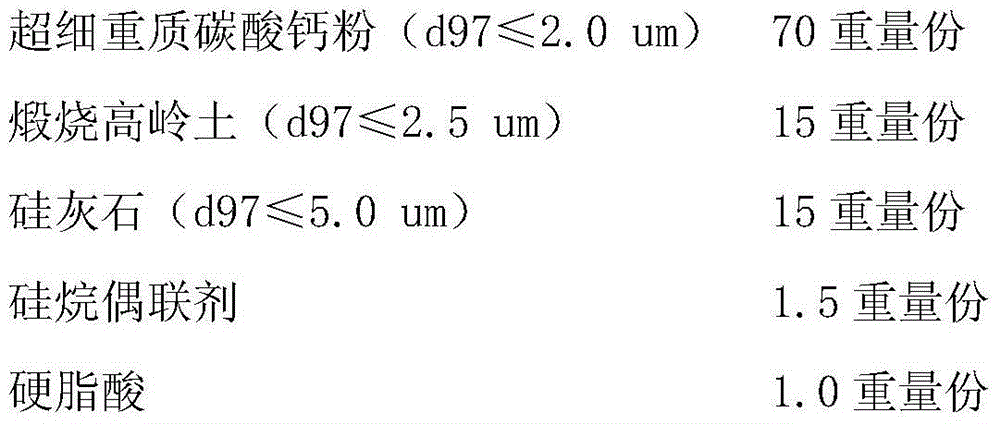

[0020] Proportion

[0021]

[0022] The model of the silane coupling agent is KH-580, produced by Nanjing Shuguang Company.

[0023] Described stearic acid model is 1801, commercially available.

[0024] The calcined kaolin and wollastonite are commercially available products.

[0025] The superfine ground calcium carbonate powder is produced by Wuhu Tongda New Material Technology Co., Ltd.

[0026] Its preparation method is:

[0027] Add superfine heavy calcium carbonate powder into the high-speed mixer, then add wollastonite powder and kaolin powder respectively, stir at high speed and heat up. When the temperature reaches 105°C, keep it warm for 8 minutes to dry off the water, and then add evenly Combined agent, heat up to 155°C, keep warm for 8 minutes, discharge the material into the intermediate hopper, cool the material to 95°C, and quantitatively add the above-mentioned preliminary modification to the three-roller continuous powder surface modification machine co...

Embodiment 2

[0029] Proportion

[0030]

[0031] The model of the silane coupling agent is KH-580, produced by Nanjing Shuguang Company.

[0032] Described stearic acid model is 1801, commercially available.

[0033] The calcined kaolin and wollastonite are commercially available products.

[0034] The superfine ground calcium carbonate powder is produced by Wuhu Tongda New Material Technology Co., Ltd.

[0035] Its preparation method is:

[0036] Add superfine heavy calcium carbonate powder into the high-speed mixer, then add wollastonite powder and kaolin powder respectively, stir at high speed and heat up, when the temperature reaches 110°C, keep it warm for 1 minute to dry off the moisture, and then add coupling Raise the temperature to 160°C, keep it warm for 7 minutes, discharge the material into the intermediate hopper, cool the material to 95°C, and quantitatively add the above-mentioned preliminary modified mixture to the three-roller continuous powder surface modification...

Embodiment 3

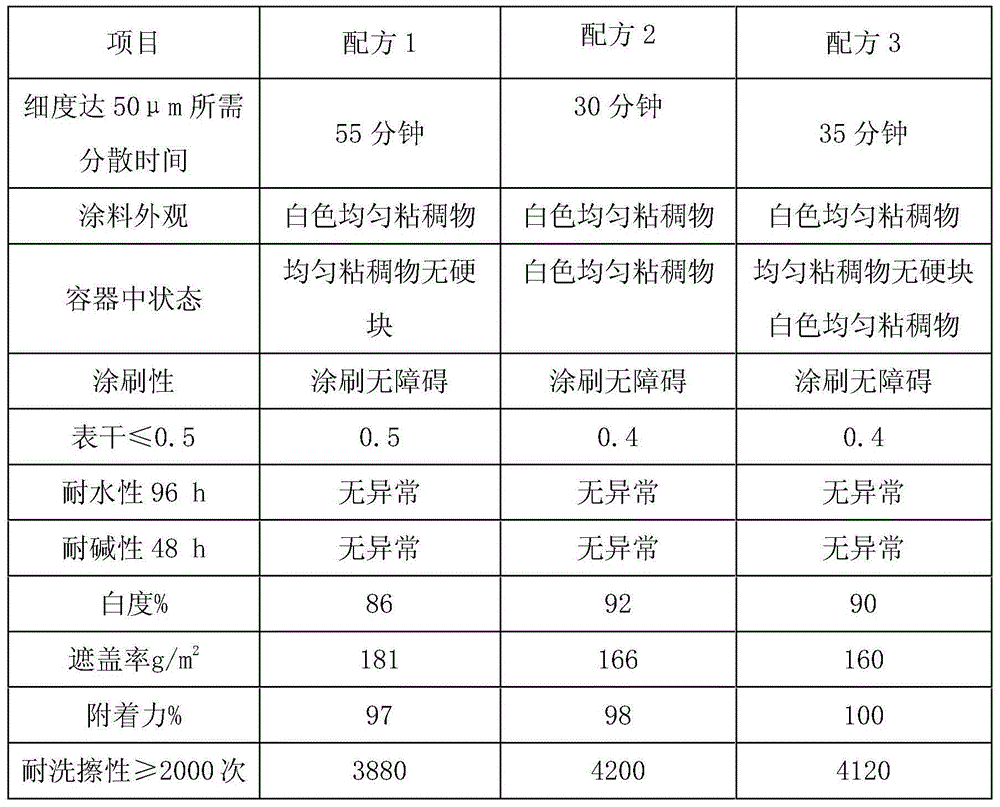

[0045] Embodiment 3: Embodiment 1, 2 are used respectively in the water-based architectural paint, and concrete scheme is as follows:

[0046] 1. Formula

[0047] Recipe 1

[0048]

[0049] Ammonia to adjust PH=7

[0050] Recipe 2

[0051] Replace 20 parts of titanium dioxide in formula 1 with 30 parts of multi-modified ultrafine non-metallic powder prepared in Example 1, and the rest are the same as formula 1.

[0052] The titanium dioxide is rutile type and imported; the precipitated barium sulfate light calcium carbonate is 600 mesh and commercially available; other materials are commercially available.

[0053] Recipe 3

[0054] Replace 20 parts of titanium dioxide in formula 1 with 32 parts of multi-modified ultrafine non-metallic powders prepared in Example 2, and the rest are the same as formula 1.

[0055] 2. Process

[0056] ① Dissolve the thickener in water

[0057] ②Add various additives and stir evenly at low speed

[0058] ③ Add powder, stir well, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com