Middle and low temperature SCR denitration catalyst with anti-poisoning performance, and preparation method thereof

A denitration catalyst and anti-poisoning technology, which can be used in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Achieve high activity, extended service life, reduced clogging and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Calcining transition metal salt cerium nitrate hexahydrate in an air atmosphere at 450°C for 2 hours to prepare cerium oxide;

[0038] 2) Put 50g of cerium oxide and 50g of phosphotungstic acid into a planetary ball mill after mixing, and rotate and grind at a speed of 180r / min for 10 hours to obtain an intermediate;

[0039] 3) Calcining the obtained intermediate at a temperature of 80° C. for 1 hour to obtain a medium-low temperature SCR denitrification catalyst with anti-sulfur and anti-poisoning properties of alkali metals and alkaline earth metals.

[0040] Catalyst activity test:

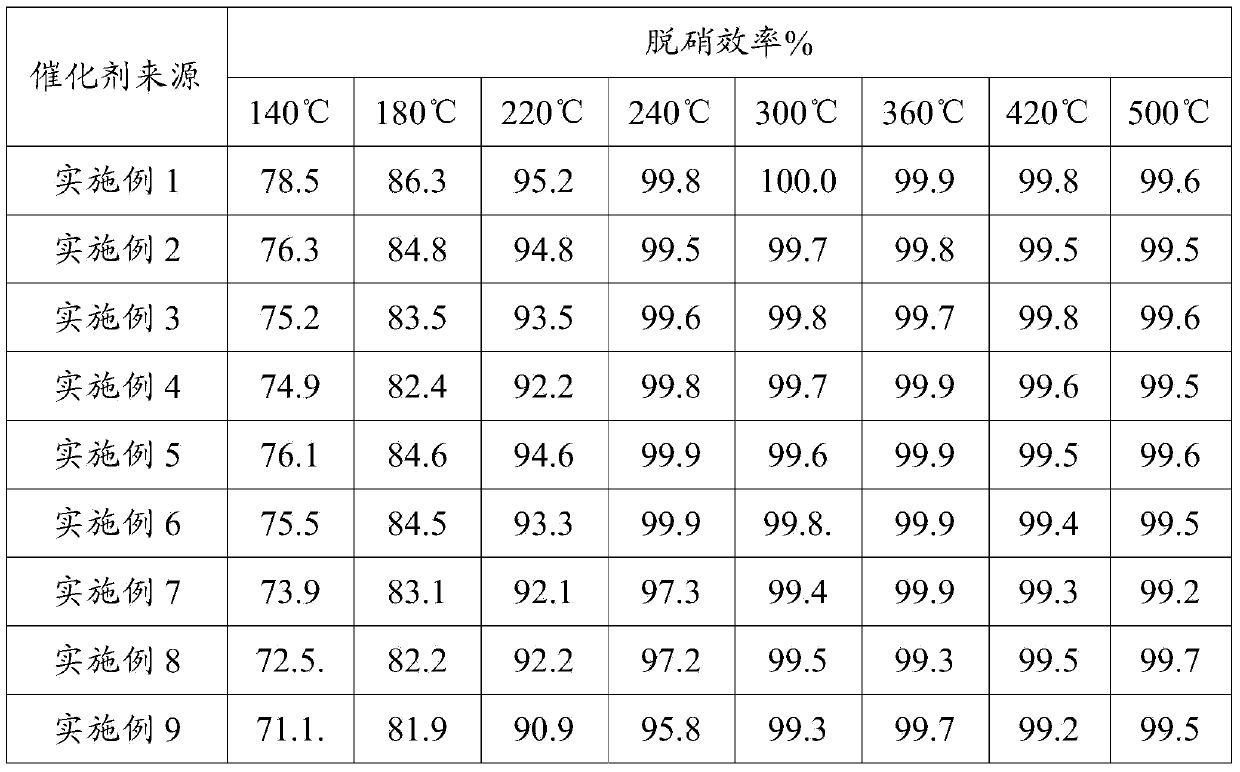

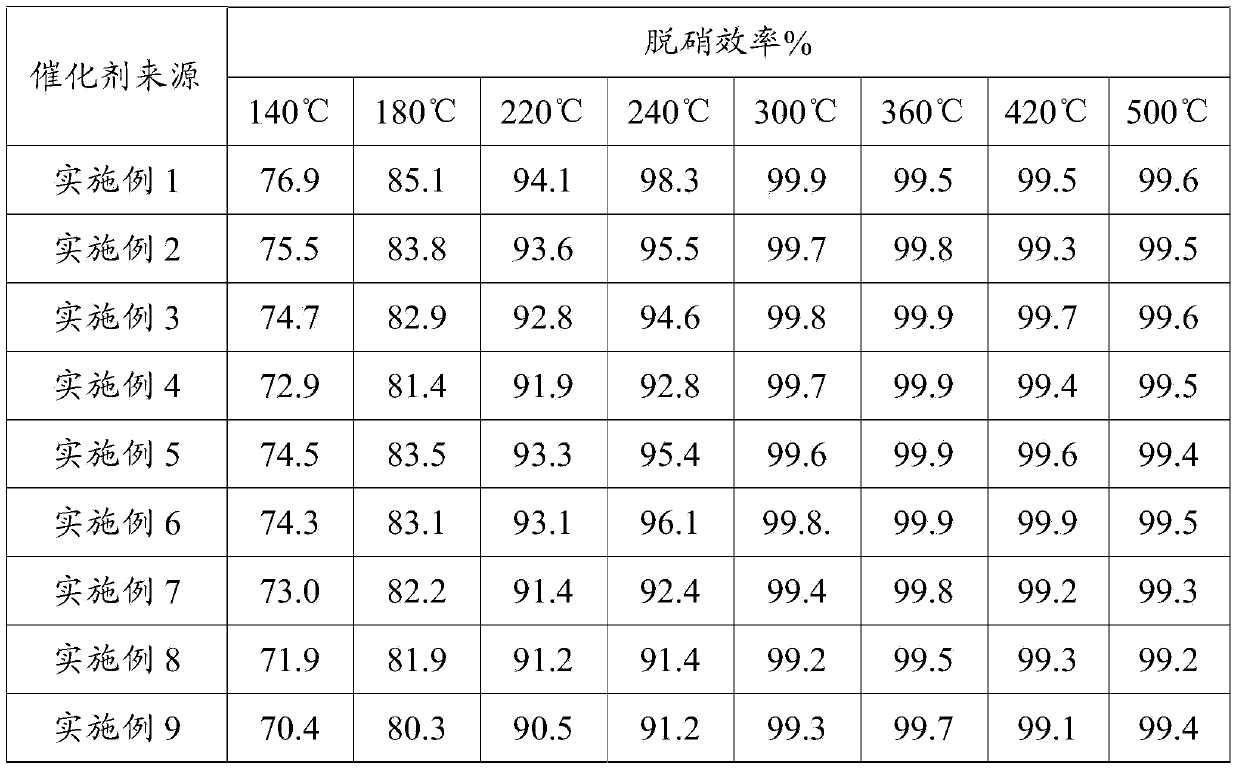

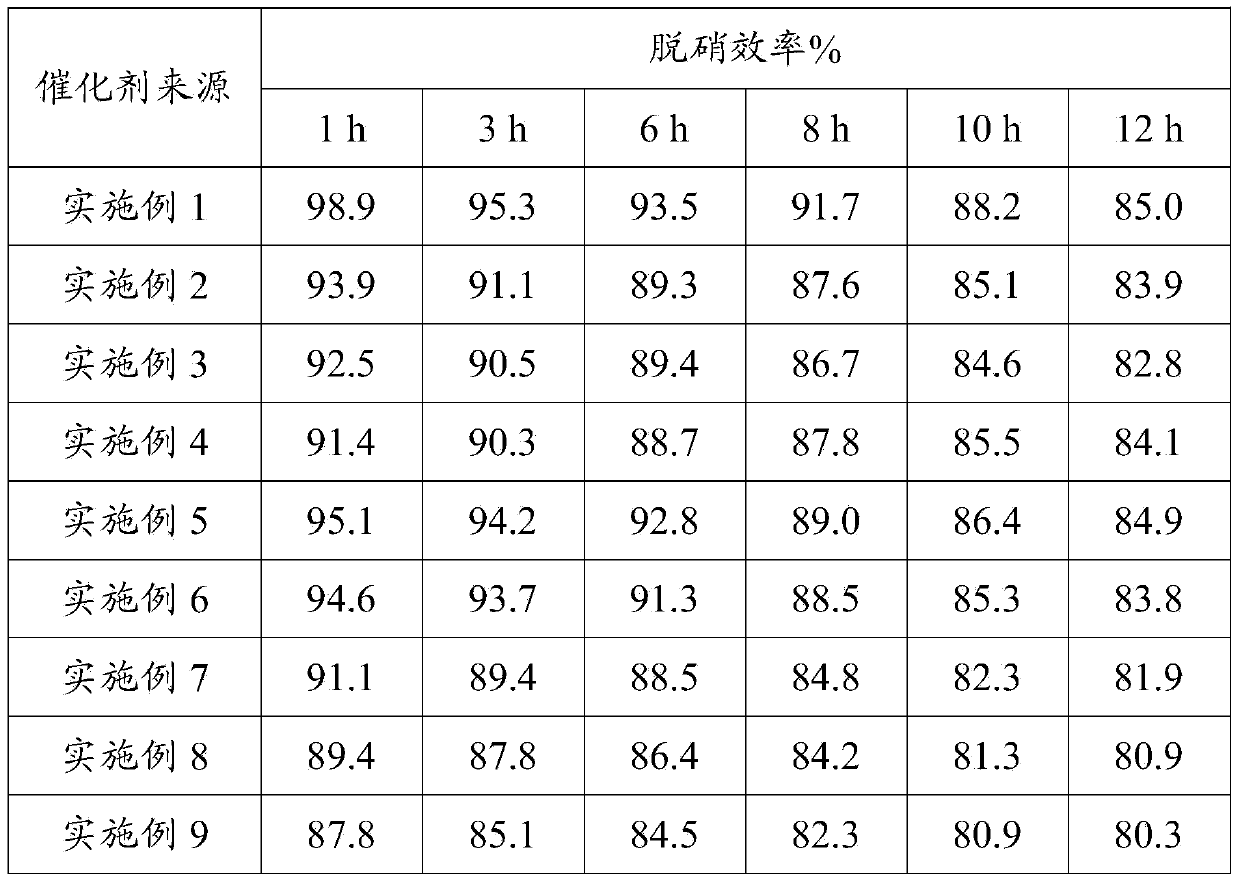

[0041] Put the prepared catalyst into a fixed-bed quartz tube reactor, and feed it with N 2 , O 2 , NO and NH 3 Composed of simulated flue gas for testing, where [NO]=600ppm, [NH 3 ]=600ppm, [O 2 ]=3%, the reaction temperature is 200~500℃, and the space velocity is 40000h -1 Under certain conditions, the denitrification efficiency is stable above 90%.

[0042] The test reactio...

Embodiment 2

[0051] 1) Calcining transition metal salt cobalt carbonate in an air atmosphere at 500°C for 2 hours to obtain cobalt oxide;

[0052] 2) Mix 50g of cobalt oxide and 50g of phosphotungstic acid into a planetary ball mill, and rotate and grind at a speed of 180r / min for 10 hours to obtain an intermediate;

[0053] 3) Calcining the obtained intermediate at a temperature of 80° C. for 1 hour to obtain a medium-low temperature SCR denitrification catalyst with anti-sulfur and anti-poisoning properties of alkali metals and alkaline earth metals.

[0054] Catalyst activity test:

[0055] Put the prepared catalyst into a fixed-bed quartz tube reactor, and feed it with N 2 , O 2 , NO and NH 3 Composed of simulated flue gas for testing, where [NO]=600ppm, [NH 3 ]=600ppm, [O 2 ]=3%, the reaction temperature is 200~500℃, and the space velocity is 40000h -1 Under certain conditions, the denitrification efficiency is stable above 90%.

[0056] The test reaction temperature is specifi...

Embodiment 3

[0065] 1) Calcining transition metal salt vanadium nitrate in an air atmosphere at 450°C for 7 hours to obtain vanadium oxide;

[0066] 2) Mix 50g of vanadium oxide and 50g of phosphotungstic acid into a planetary ball mill, and rotate and grind at a speed of 180r / min for 10 hours to obtain an intermediate;

[0067] 3) Calcining the obtained intermediate at a temperature of 80° C. for 1 hour to obtain a medium-low temperature SCR denitrification catalyst with anti-sulfur and anti-poisoning properties of alkali metals and alkaline earth metals.

[0068] Catalyst activity test:

[0069] Put the prepared catalyst into a fixed-bed quartz tube reactor, and feed it with N 2 , O 2 , NO and NH 3 Composed of simulated flue gas for testing, where [NO]=600ppm, [NH 3 ]=600ppm, [O 2 ]=3%, the reaction temperature is 200~500℃, the space velocity is 40000h -1 Under certain conditions, the denitrification efficiency is stable above 90%.

[0070] The test reaction temperature is specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com