Method for preparing lanthanum-free and cobalt-free calcium permanent magnet ferrite materials

A permanent magnet ferrite and main component technology, applied in the field of permanent magnet ferrite material preparation, can solve problems such as difficulty in ion co-precipitation, high pre-burning temperature, etc., and achieve industrial production, controllable process conditions, and reaction temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

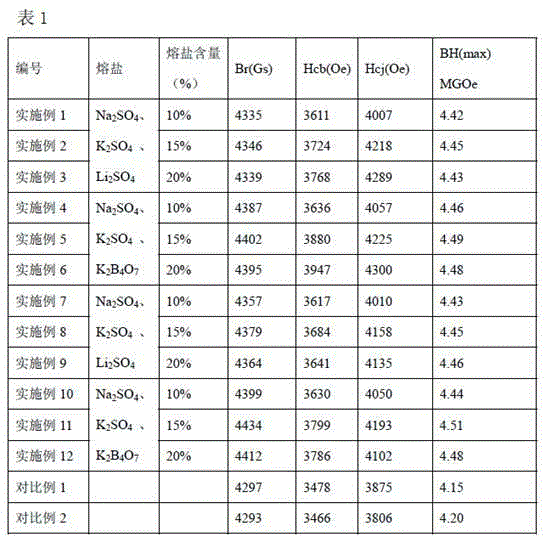

Embodiment 1

[0041] Embodiment 1: The main component raw material is pressed (1-x-y) AO · xBaO · Bi 2 o 3 ·(n-z-w)Fe 2 o 3 ·2zZnO·2wMnO composition formula, A is Ca. Among them, x=0.21, y=0.03, z=0.2, w=0.005, n=5.4 weigh the weight (the main component raw material is: Fe 2 o 3 , Bi 2 o 3 , Mn 2 o 3 , BaCO 3 , CaCO 3 , ZnO), and then weigh the molten salt: Na 2 SO 4 +K 2 SO 4 +Li 2 SO 4 (Respective molar percentages: 29.5%, 30%, 40.5%). The weight of the molten salt is 10% based on the total weight of the main components and each raw material. Put them together in a ball mill for wet ball milling. The ball milling time is 7 hours (average particle size 0.6-1μm), After the obtained mixture was dried, it was kept at 500°C for 2 hours under atmospheric conditions, then the temperature was raised to 920°C at 3°C / min, and the heat was kept for 3 hours. The particle size D50 is 2.8 μm. Then weigh the pre-fired powder and transfer it to the sedimentation tank. After washing the...

Embodiment 2

[0042] Example 2 The amount of molten salt is 15% of the total weight of each raw material as the main component, and the rest are the same as in Example 1.

Embodiment 3

[0043] The amount of molten salt in embodiment 3 is mainly composed of 20% of the total weight of each raw material, and the rest are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com