High-F-ratio leech oligopeptide, and enzymatic hydrolysis preparation method and application thereof

A leech and oligopeptide technology, which is applied in the preparation method of peptides, from leech inhibitors, applications, etc., can solve the problems of single product type and forgetting, and achieve the effect of simple preparation process and easy intestinal absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

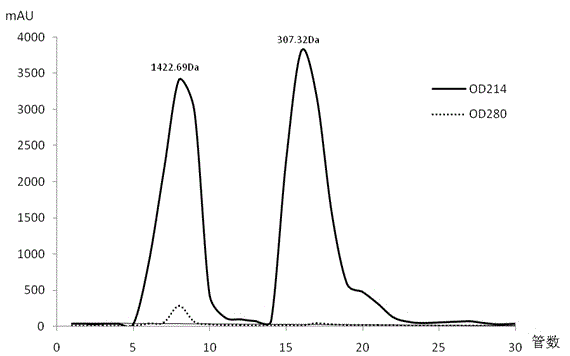

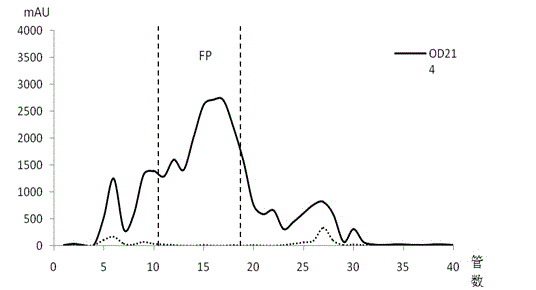

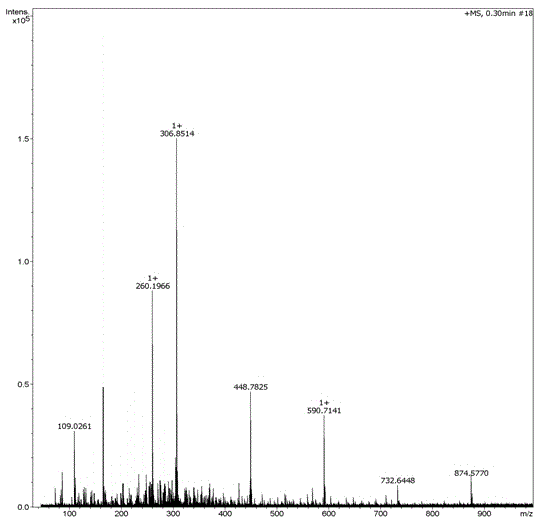

[0043] Take 500g of dried leeches, clean them, soak them in deionized water and ethanol for 12 hours, put them in an oven at 45°C and dry them until the water content is less than 3%, grind them into fine powder at high speed, add water to dissolve, and the weight ratio of dry powder to water is 5: 100 to prepare the suspension, and homogenize it with a high-speed homogenizer, then adjust the pH to 10 with 1mol / L NaOH, soak for 20min; then adjust the pH to 9, add Alcalase2.4L alkaline protease (Novozymes company, Denmark), the reaction temperature was maintained at 60°C, and the enzymolysis was carried out for 4 hours; boiled for 10 minutes, inactivated, cooled, centrifuged at 8000r / min for 5 minutes, the supernatant was collected, the pH was adjusted to 7.0, and papain was added at 4000U / g pro ( Novozymes Company, Denmark), the reaction temperature was kept at 60°C, and the enzymolysis was carried out for 4 hours; boiled for 10 minutes to inactivate the enzyme, cooled, centrif...

Embodiment 2

[0045] Take 500g of dried leeches, clean them, soak them in deionized water and ethanol for 10 hours, put them in an oven at 45°C and dry them until the water content is less than 3%, grind them into fine powder at high speed, add water to dissolve, and the weight ratio of dry powder to water is 8: 100 to prepare the suspension, and homogenize it with a high-speed homogenizer, then adjust the pH to 11 with 1mol / L NaOH, soak for 50min; then adjust the pH to 10, add Alcalase2.4L alkaline protease (Novozymes company, Denmark), the reaction temperature was maintained at 50°C, and the enzymolysis was carried out for 3 hours; boiled for 20 minutes, inactivated, cooled, centrifuged at 6000r / min for 10 minutes, the supernatant was collected, the pH was adjusted to 8.0, and papain was added at 6000U / g pro ( Novozymes Company, Denmark), the reaction temperature was kept at 60°C, and the enzymolysis was carried out for 3 hours; boiled for 15 minutes to inactivate the enzyme, cooled, centr...

Embodiment 3

[0047] Take 500g of dried leeches, clean them, soak them in deionized water and ethanol for 15 hours, put them in an oven at 45°C and dry them until the water content is less than 3%, grind them into fine powder at high speed, add water to dissolve, and the weight ratio of dry powder to water is 2: Prepare the suspension at 100, and homogenize with a high-speed homogenizer, then adjust the pH to 8 with 1mol / L NaOH, and soak for 60 minutes; then adjust the pH to 8.5, add Alcalase2.4L alkaline protease ( Novozymes company, Denmark), keep the reaction temperature at 65°C, enzymolysis for 3.5h; boil for 10min, inactivate the enzyme, cool, centrifuge at 5000r / min for 20min, collect the supernatant, adjust the pH to 7.0, add papaya at 5000U / g pro Protease (Novozymes, Denmark), the reaction temperature was kept at 55°C, and the enzymolysis was carried out for 2.5 hours; boiled for 10 minutes, inactivated, cooled, centrifuged at 8000r / min for 10 minutes, and the supernatant was collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com