Method for deproteinizing and decoloring oat beta-glucan

A dextran and deproteinization technology, which is applied in the field of refining and processing plant active ingredients, can solve problems affecting the biological activity of polysaccharides, achieve good results, avoid losses, and have high removal rates of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

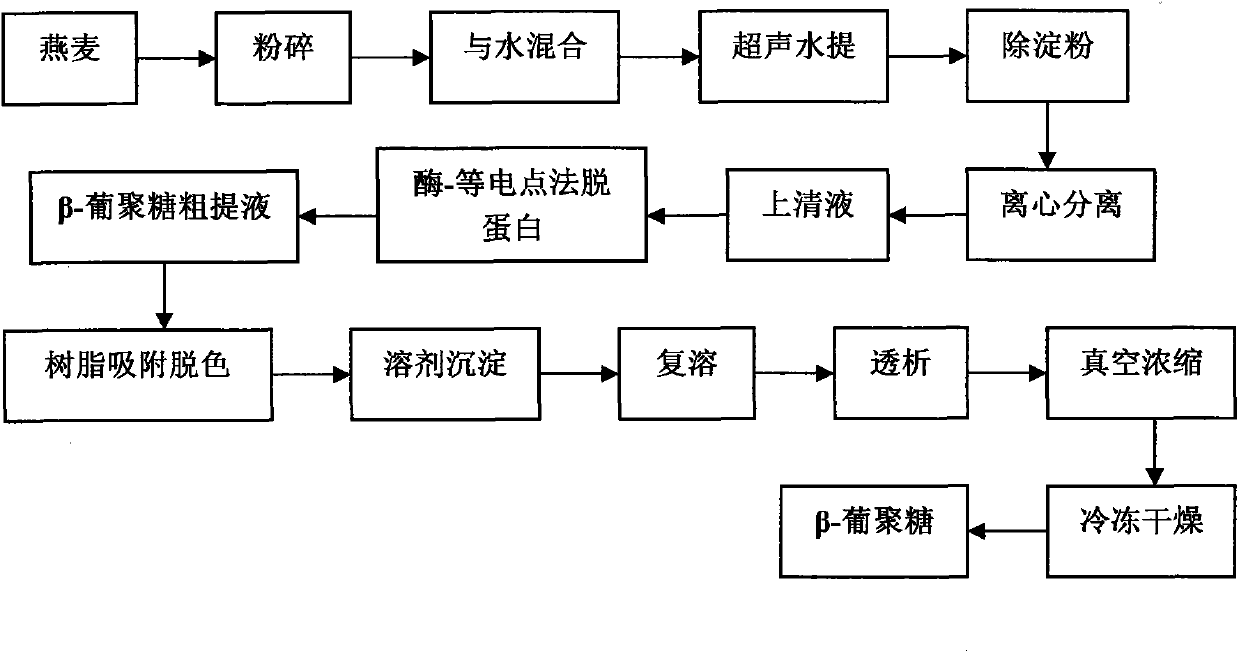

Image

Examples

Embodiment 1

[0019] The oatmeal is crushed and mixed with water to form a mixed solution, and the mixed solution is subjected to ultrasonic water extraction to obtain a β-glucan extract, and α-amylase is added to the extract to enzymatically degrade the starch, and the supernatant is obtained by centrifugation after enzymatic hydrolysis solution, add bromelain and trypsin with a mass ratio of 1:3 to the supernatant to carry out enzymatic hydrolysis and deproteinization to obtain an enzymolysis solution, then use 10% hydrochloric acid solution to adjust the pH of the enzymolysis solution to 4.4, then let it stand for a certain period of time, and centrifuge The supernatant was obtained, and the supernatant was concentrated in vacuo to obtain the crude extract of β-glucan, and the crude extract of β-glucan was subjected to the AB -8 type resin is adsorbed and decolorized for 80 minutes. After decolorization, ethanol precipitation and ammonium sulfate precipitation are carried out. After the p...

Embodiment 2

[0021] The oatmeal is crushed and mixed with water to form a mixed solution, and the mixed solution is subjected to ultrasonic water extraction to obtain a β-glucan extract, and α-amylase is added to the extract to enzymatically degrade the starch, and the supernatant is obtained by centrifugation after enzymatic hydrolysis solution, add bromelain and trypsin with a mass ratio of 1:4 to the supernatant to carry out enzymatic hydrolysis and deproteinization to obtain an enzymatic hydrolysis solution, then use 10% hydrochloric acid solution to adjust the pH of the enzymatic hydrolysis solution to 4.2, then let it stand for a certain period of time, and centrifuge The supernatant was obtained, and the supernatant was concentrated in vacuum to obtain a crude β-glucan extract, and the crude β-glucan extract was subjected to the AB -8 type resin adsorption and decolorization for 100 minutes, after decolorization, ethanol precipitation and ammonium sulfate precipitation were carried o...

Embodiment 3

[0023] The oatmeal is crushed and mixed with water to form a mixed solution, and the mixed solution is subjected to ultrasonic water extraction to obtain a β-glucan extract, and α-amylase is added to the extract to enzymatically degrade the starch, and the supernatant is obtained by centrifugation after enzymatic hydrolysis solution, add bromelain and trypsin with a mass ratio of 1:2 to the supernatant to carry out enzymatic hydrolysis and deproteinization to obtain an enzymatic hydrolysis solution, then use 10% hydrochloric acid solution to adjust the pH of the enzymatic hydrolysis solution to 4.6, then let it stand for a certain period of time, and centrifuge The supernatant was obtained, and the supernatant was concentrated in vacuum to obtain the crude extract of β-glucan, and the crude extract of β-glucan was subjected to the AB -8 type resin adsorption and decolorization for 60 minutes, after decolorization, ethanol precipitation and ammonium sulfate precipitation were ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com