Catalytic converter for motorcycle exhaust treatment and preparation method thereof

A catalytic converter and tail gas treatment technology, which is applied in the direction of chemical instruments and methods, separation methods, mechanical equipment, etc., can solve the problems of low control accuracy, affecting the activity and durability of catalytic converters, etc., and achieve improved conversion rate and synergistic Strong catalytic effect and enhanced synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

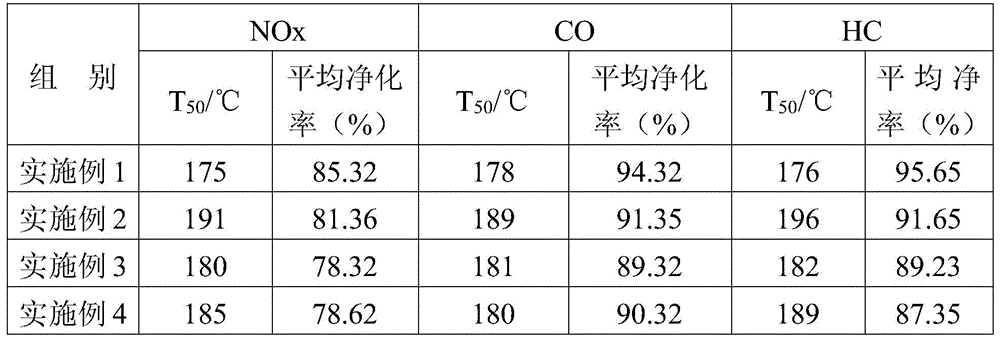

Examples

Embodiment 1

[0030] (1) Preparation of powder

[0031]①Impregnate 16.03g of palladium nitrate on 97.5g of oxygen storage material. The specific method is to pour 16.03g of palladium nitrate into a 2L plastic cup, then add water to the plastic cup until the solution is 200g, stir for 10min, and then add oxygen storage 97.5g of material, stirred for 1 hour, put the stirred powder into an oven for drying, the drying temperature is 90°C, and the drying time is 6h, put the dried powder into a muffle furnace for roasting, the roasting temperature is 550°C, Roasting time is 2h; Make powder D1, the weight percent content of palladium in D1 is 2.5%;

[0032] 2. palladium nitrate 16.03g is impregnated on the 97.5g aluminum oxide material, makes powder D2, and the weight percent content of palladium in D2 is 2.5%;

[0033] ③ 0.69g of platinum nitrate was impregnated on 99.8g of oxygen storage material to make powder P1, and the weight percent content of platinum in P1 was 0.22%;

[0034] 4. Rhodium...

Embodiment 2

[0045] (1) 60.23g of osmium nitrate is impregnated on 66.92g of oxygen storage material to make powder D1; 60.23g of osmium nitrate is impregnated on 66.92g of alumina material to make powder D2; 21.34g of iridium nitrate is impregnated in On 97.09g of oxygen storage material, make powder P1; impregnate 25.67g of ruthenium nitrate on 97.09g of oxygen storage material, make powder H1; impregnate 46.13g of cobalt nitrate on 89.69g of oxygen storage material, make powder Material T1; 52.08 g of ferric nitrate was impregnated on 89.69 g of alumina material to make powder T2.

[0046] The above-mentioned oxygen storage material is cerium-zirconium solid solution.

[0047] (2) Prepare the metal carrier, the carrier specification is: mesh number 300cell / in 2 , the wall thickness is 1.0mm, the outer diameter is Ф45mm, the length of the metal carrier is 120mm, and the length ratio of A1 section, A2 section and A3 section is 0.5:0.5:1.

[0048] (3) Get 57gT1, 40gT2, 3g aluminum oxide,...

Embodiment 3

[0054] (1) 8.85g palladium nitrate is impregnated on 98.62g oxygen storage material, makes powder material D1; Palladium nitrate 8.85g is impregnated on 98.62g alumina material, is made powder material D2; Platinum nitrate 0.38g is impregnated in On 99.9g of oxygen storage material, make powder P1; impregnate 1.88g of ferric nitrate on 99.95g of oxygen storage material, make powder T1; impregnate 2.13g of nickel nitrate on 99.95g of alumina material, make powder Material T2.

[0055] The above-mentioned oxygen storage material is cerium-zirconium solid solution.

[0056] (2) Prepare the metal carrier, the carrier specifications are: mesh number 300cell / in2, wall thickness 1.0mm, outer diameter Ф45mm, metal carrier length 70mm, and the length ratio of A1, A2 and A3 sections is 5:0:1.

[0057] (3) Get 57gT1, 40gT2, 3g aluminum oxide, 3g acetic acid and 100g pure water and mix, and ball mill to make slurry J1, the solid content of J1 is 50%;

[0058] (4) Get 20gD1, 11.64gD2, 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com