Flavored fermented soybean milk formula and preparation method thereof

A technology for fermented soybean milk and flavor, applied in the field of new fermented soybean milk formulation and preparation, can solve the problems of lack of lactose, no large-scale production, reduced nutrient absorption rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

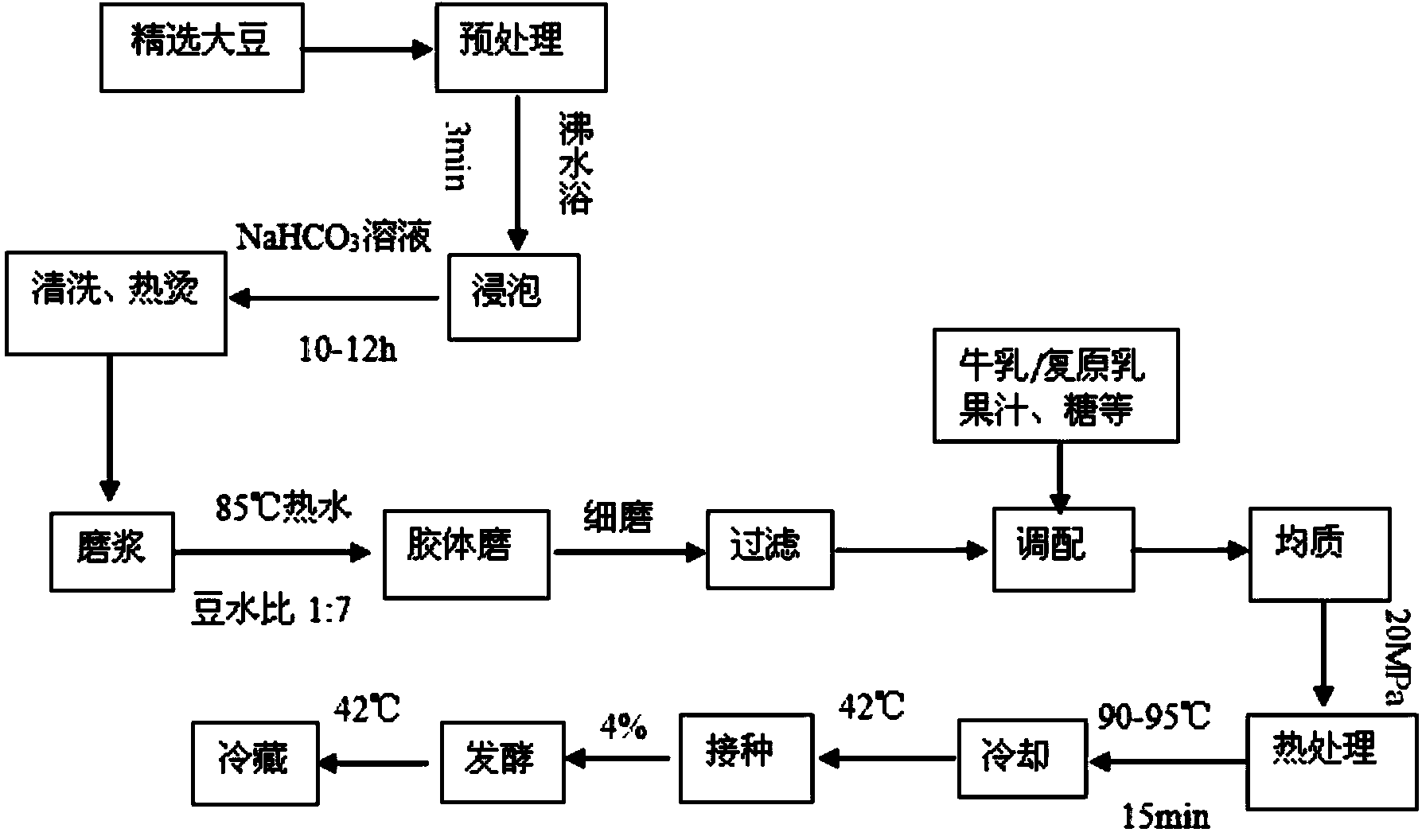

Method used

Image

Examples

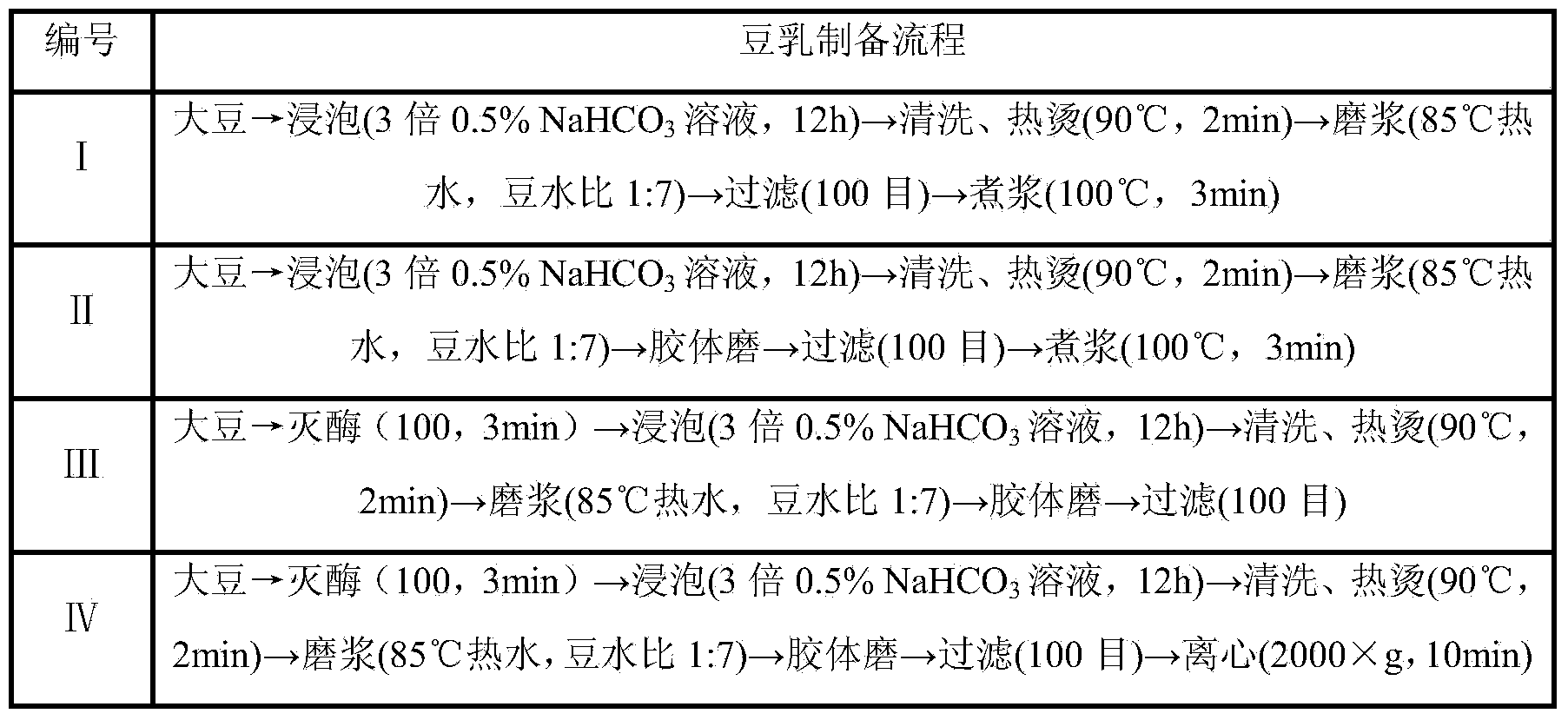

preparation example Construction

[0029] 2. Preparation of Flavored Fermented Soymilk Formula

[0030] (1) Effects of different fruit juice types and addition amounts on the quality of flavored fermented soybean milk

[0031] Five kinds of fruits used in the present invention, kiwi fruit, orange, apple, juicy peach and tomato, are all purchased from supermarkets. Wash and blanch the 5 kinds of fruits for 1 min, peel and remove the stalks, centrifuge at 2000×g for 5 min after juicing, and wash with saturated Na 2 CO 3 and 20% citric acid solution to adjust the pH of the obtained fruit juice to 4.0, and then adjust the sugar content to 12°Bix with saturated sucrose solution, then pasteurize, and store in a refrigerator at 4°C for future use.

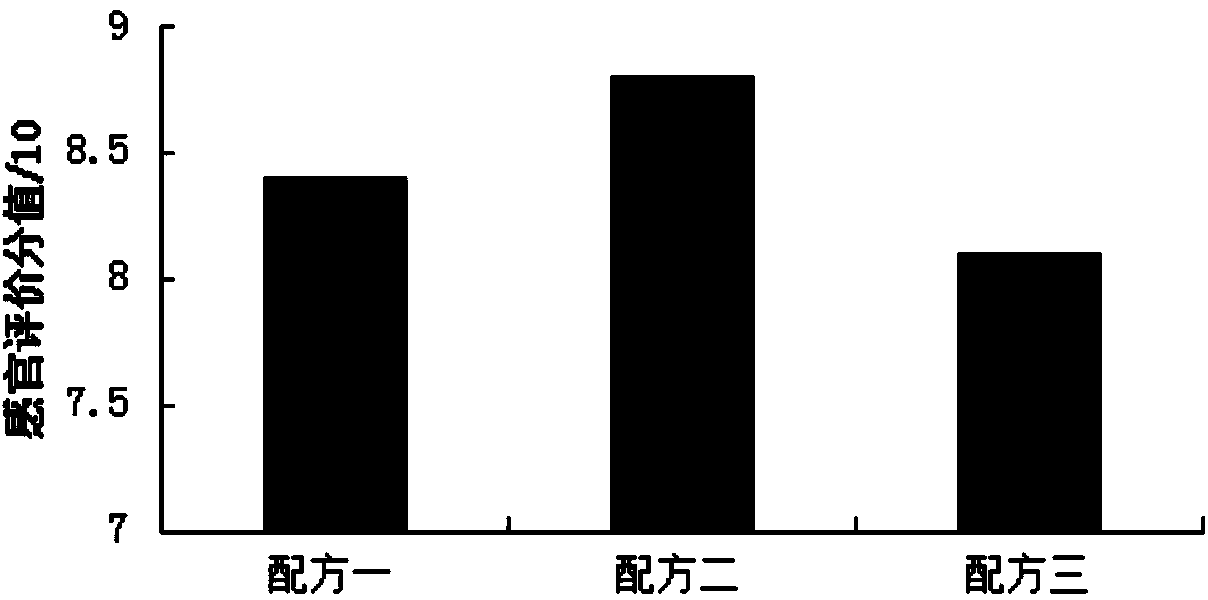

[0032] Soymilk and cow's milk (or reconstituted milk) prepared by the above process III are mixed at a volume ratio of 7:3, and 5%, 7%, 9% (v / v) fruit juice and 6% (w / v) sucrose are added respectively , after heat treatment, inoculated with 4% (v / v) yogurt starter, ferm...

Embodiment 1

[0056] Such as figure 2 100kg of impurity-removed soybeans were weighed, boiled at 100°C for 3 minutes to kill enzymes, and then soaked in 300 liters of 0.5% (w / v) NaHCO 3 In the solution for 12 hours, wash the soybeans and scald them with 90°C hot water for 2 minutes, then use 700 liters of 85°C hot water for grinding, mix the ground soybean milk and bean dregs, finely grind them through a colloid mill, and filter the bean dregs through a 100-mesh sieve. soy milk. After the raw milk is standardized, take 300 liters and mix it with 700 liters of soybean milk, add 8kg of sucrose, 1kg of D40 whey powder and 70 liters of compound fruit juice, homogenize at 20MPa, heat treat at 90-95°C for 15 minutes, and then cool to 42 ℃, inoculated with 40 liters of starter cultured by Streptococcus thermophilus CGMCC No: 3622, fermented to curd at 42 ℃, and refrigerated at 4 ℃ for 24 hours to make 1000 liters of flavored fermented soybean milk.

Embodiment 2

[0058] Weigh 36kg of whole milk powder, reconstitute it into 12% (w / w) reconstituted milk with 264kg of deionized water, mix with 700 liters of soybean milk prepared in Example 1, add 8kg of sucrose, 0.8kg of D40 whey powder And 60 liters of compound fruit juice, homogenized at 20MPa, heat-treated at 90-95°C for 15 minutes, then cooled to 42°C, inoculated with 30 liters of starter cultured by Streptococcus thermophilus CGMCC No: 3622, fermented at 42°C until curdling, Refrigerate at 4°C for 24 hours to make 1000 liters of flavored fermented soybean milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com