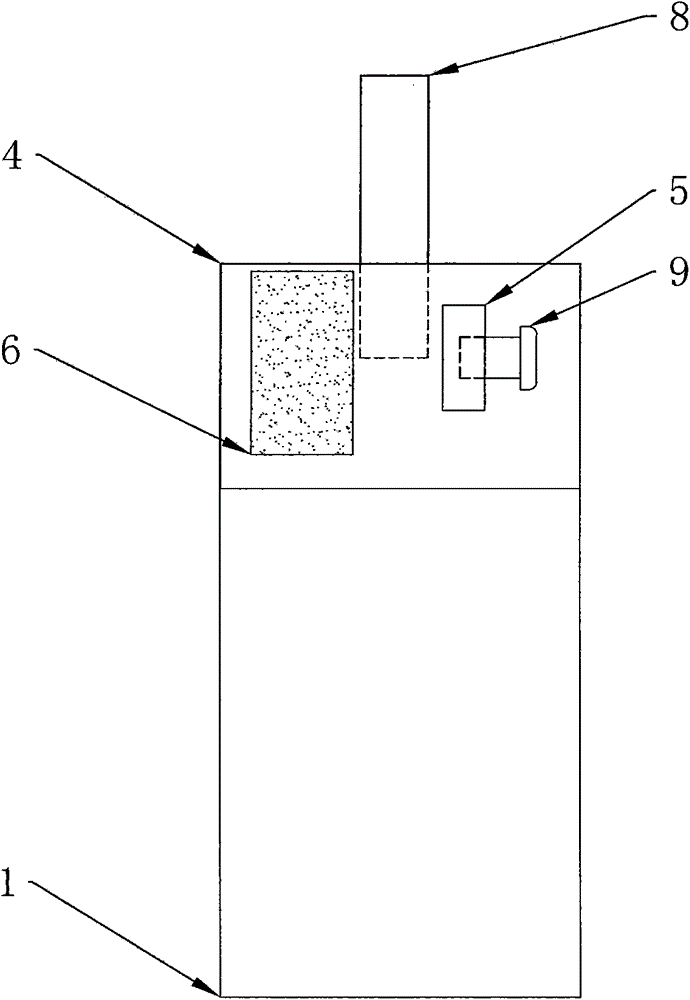

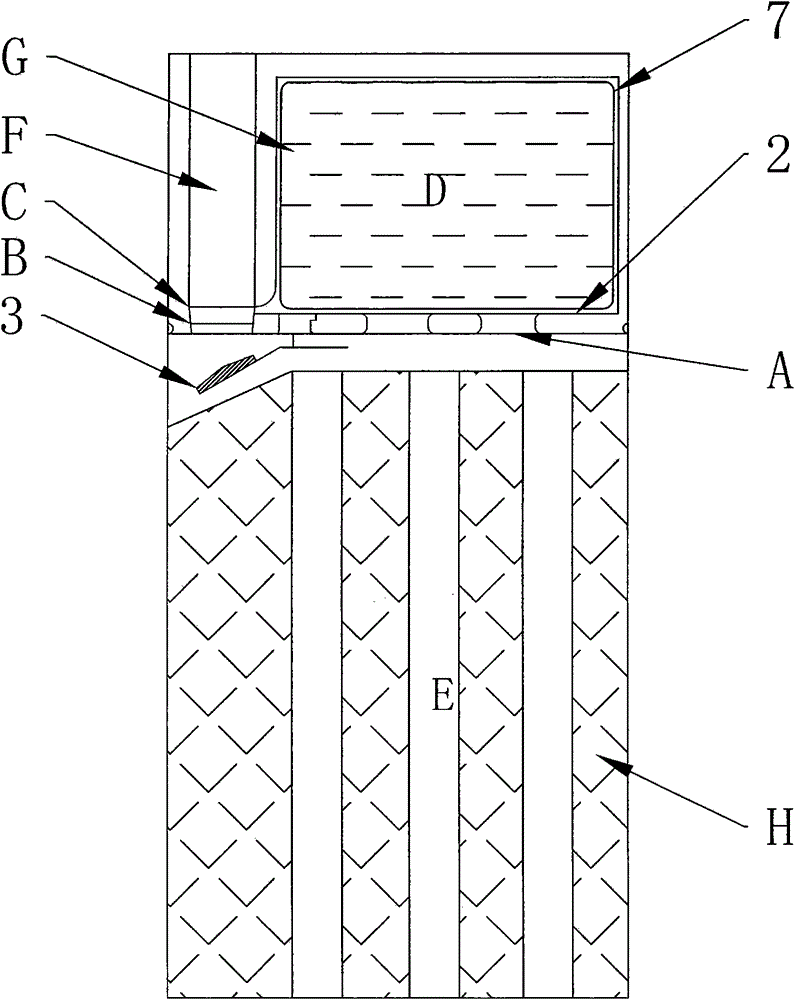

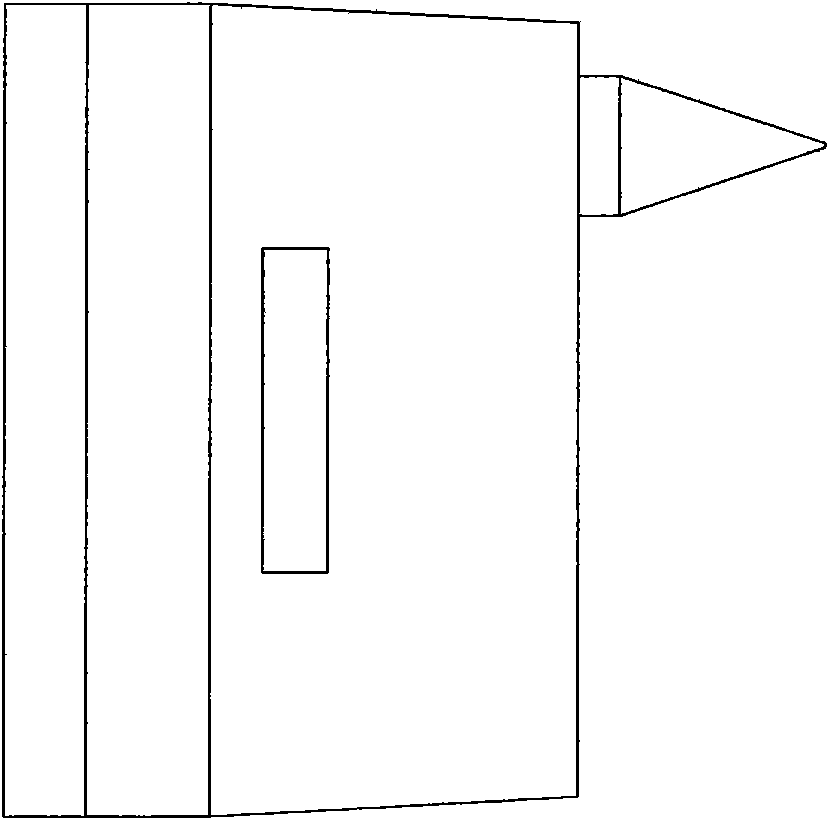

Portable oxygen production apparatus

An oxygen-generating device and a substrate technology, applied in the direction of oxygen preparation, etc., can solve the problems such as portability is difficult to achieve, achieve the effects of improving portability and practicability, optimizing device structure, and avoiding phase transition substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-4

[0038] Oxidized urea synthesis Mix food-grade urea, hydrogen peroxide aqueous solution, stabilizer, and coating agent, stir at 35 degrees Celsius for a certain period of time, and precipitate product crystals at low temperature. In the stage of solid precipitation, keep stirring to make the crystal particles small and uniform. The crystal particle size was obtained by visually observing the diameter of 10 crystal particles with a low-power microscope, and repeated 3 times. In the vacuum filtration stage, the filtration time is controlled to obtain urea peroxide with different mother liquor contents. The actual mother liquor content is about 1%-12%. The specific results are shown in Table 1.

[0039] By example 1-4 see stirring speed has direct impact on the crystal particle size that generates when urea peroxide crystallization. The crystal particle size has a direct impact on the substrate mother liquor content, molding pressure, shape, physical stability and dissolution r...

example 5-10

[0044] Examples 5-10 were carried out with the results of Example 3. In the stage of oxidized urea compression molding, because the pressure is different from that of the mold, the remaining amount of mother liquor and the physical stability of the particles after molding are also different. The final substrate mother liquor content is obtained by subtraction method after drying under reduced pressure at 50 degrees centigrade under 0.05 atmospheric pressure. The physical stability is obtained by the actual loading of the prototype, and the integrity of the 2-meter free fall after 2 drops. The actual results are shown in Table 2.

[0045] Table 2. Example 5-10 Experimental Results

[0046]

[0047] From examples 5-10, it can be seen that the molding conditions of the substrate have a direct impact on the mother liquor content and physical stability of the substrate. A substrate with a moderate mother liquor content can effectively increase the overall available oxygen con...

example 11-14

[0049] Examples 11-13 were carried out with the results of Example 9. The measured effective oxygen content of Example 9 is 19.7%. Add a certain amount of water / ethylene glycol solvent and catalyst into a container containing 100 g of a honeycomb-type oxygen-generating substrate at a room temperature of 25 degrees Celsius. Measure the solution temperature and oxygen generation rate in the vessel. Add example 14 as a contrast, and the contrast oxygen-generating substrate is honeycomb sodium peroxycarbonate.

[0050] Table 3. Example 11-14 Experimental Results

[0051]

[0052] The mass ratio of solvent and urea peroxide has a direct impact on system temperature and oxygen generation rate. The larger the amount of solvent used, the smaller the temperature fluctuation during the oxygen production process of the system, and the more stable the oxygen generation rate, but too much solvent will destroy the portability of the device. The mass ratio of solvent to urea peroxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com