Metal nanoparticle-doped columbate luminescent material and preparation method thereof

A technology of metal nanoparticles and luminescent materials, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of reducing the luminous efficiency of phosphors, shortening the service life, low luminous efficiency, etc., and achieving the process conditions are not harsh, easy to achieve, high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

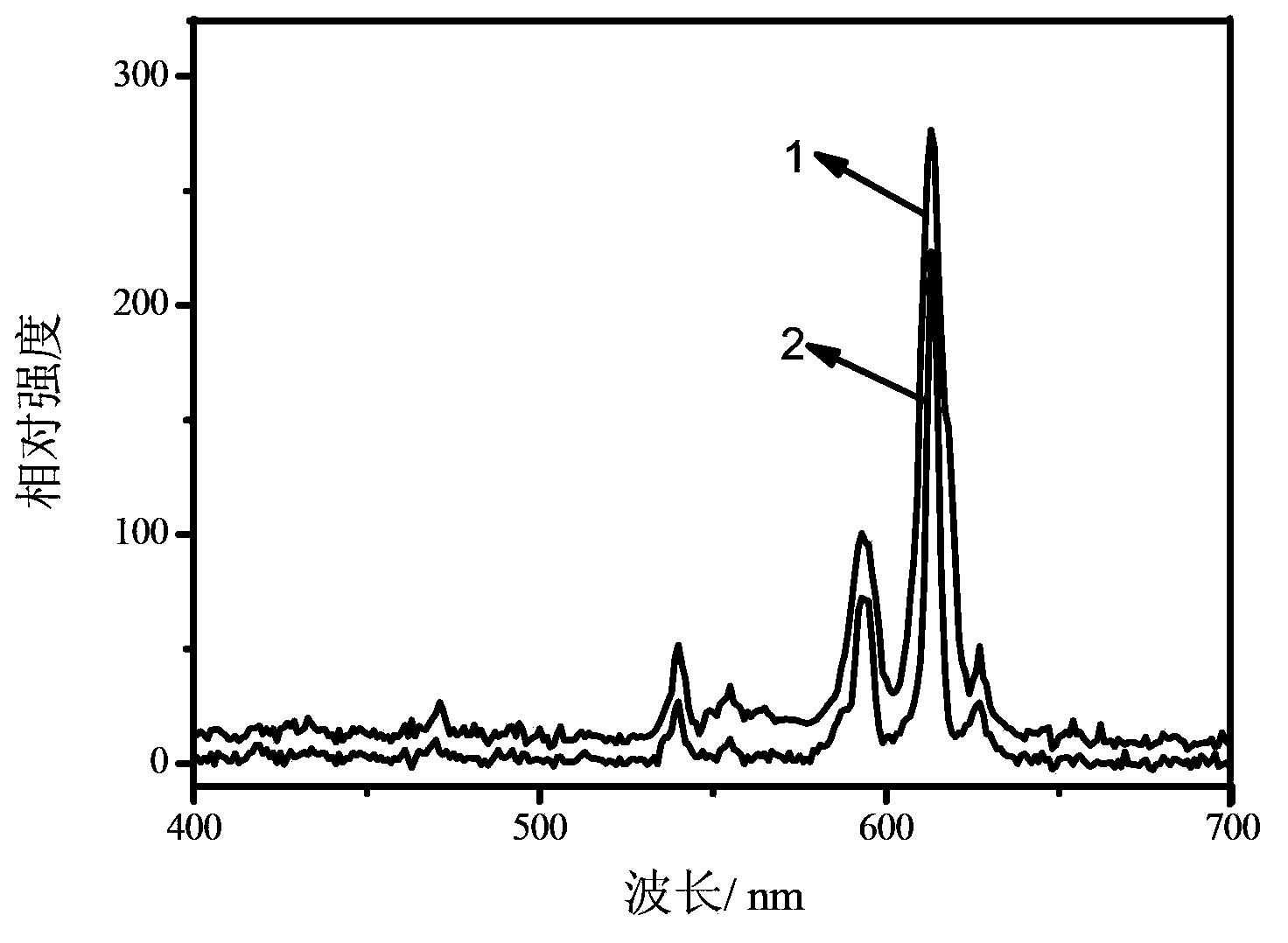

Image

Examples

Embodiment 1

[0029] Preparation of Gd by sol-gel method 1.98 CaNbO 7 :Eu 0.02 ,Pd 1×10 -5

[0030] Preparation of Pd-containing nanoparticle sol: Weigh 0.22 mg palladium chloride (PdCl 2 2H 2 O) be dissolved in the deionized water of 10mL; Under the condition of magnetic stirring, 11.0mg sodium citrate and 4.0mg sodium lauryl sulfate are dissolved in the above-mentioned palladium chloride solution; Weigh 0.38mg sodium borohydride and dissolve in 100mL deionized water to obtain a concentration of 1×10 -4 mol / L sodium borohydride solution; under the condition of magnetic stirring, quickly add 10mL of the above-mentioned sodium borohydride solution to the above-mentioned palladium chloride solution, react for 20min, and obtain 20mL of Pd nanoparticles with a concentration of 5×10 -5 mol / L of sol.

[0031] Weigh 33.2263gNb 2 o 5 And 14.0275g KOH uniform mixing, calcined at 350 ℃ for 2h to obtain soluble potassium niobate. Dissolve potassium niobate in distilled water, add nitric acid...

Embodiment 2

[0035] Preparation of Gd by sol-gel method 1.9 CaNbO 7 :Eu 0.1 , Ag 2.5×10 -4:

[0036] Preparation of Ag nanoparticles sol: weigh 3.4 mg silver nitrate (AgNO 3 ) was dissolved in 18.4mL of deionized water; under the condition of magnetic stirring, 42mg of sodium citrate was dissolved in the above silver nitrate solution; 5.7mg of sodium borohydride was weighed and dissolved in 10mL of deionized water to obtain a concentration of 1.5×10 -2 mol / L sodium borohydride solution; under the condition of magnetic stirring, add 1.6mL of the above-mentioned sodium borohydride solution to the above-mentioned silver nitrate solution at one time, and continue to react for 10min to obtain 20mL of Ag nanoparticles with a concentration of 1×10 -3 mol / L of sol.

[0037] Nb 5+ The preparation of oxalic acid solution is identical with embodiment 1.

[0038] Weigh 2.6088g Gd(NO 3 ) 3 , 0.9238g Sc (NO 3 ) 3 , 0.1352g Eu(NO 3 ) 3 and 4mL1mol / L prepared Nb 5+ Put the oxalic acid soluti...

Embodiment 3

[0043] Preparation of Gd by sol-gel method 1.5 CaNbO 7 :Eu 0.5 ,Pt 5×10 -3

[0044] Containing the preparation of Pt nanoparticle sol: take by weighing 25.9mg chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) be dissolved in 17mL of deionized water; under the condition of magnetic stirring, 400mg sodium citrate and 600mg sodium dodecylsulfonate are dissolved in the above-mentioned chloroplatinic acid solution; 1.9mg sodium borohydride is weighed and dissolved in 10mL deionized water to obtain a concentration of 5 x 10 -3 mol / L sodium borohydride solution; at the same time prepare 10mL concentration of 5×10 -2 mol / L hydrazine hydrate solution; under the condition of magnetic stirring, first add 0.4mL of the above-mentioned sodium borohydride solution dropwise to the above-mentioned chloroplatinic acid solution, after reacting for 5min, then add 2.6mL of the above-mentioned hydrazine hydrate solution to the above-mentioned chloroplatinic acid solution Hydrazine solution, continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com