Method for functionally modifying surface of conductive substrate

A technology of surface functionalization and conductive substrate, applied in the direction of electrolytic organic material coating, etc., can solve problems such as hindering the application of polydopamine surface modification technology, reducing the effective utilization of dopamine molecules, increasing the surface roughness of the coating, etc., to achieve fast polymer Effect of coating formation rate, shortening polymerization time, avoiding the formation of polymer particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

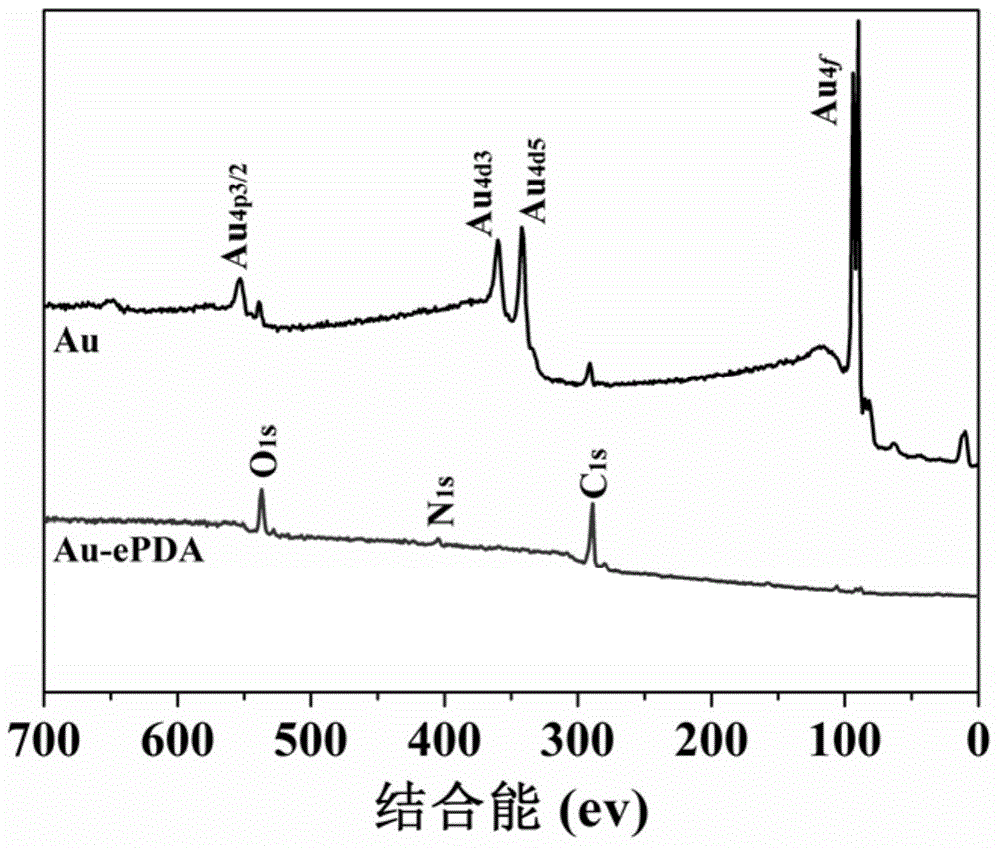

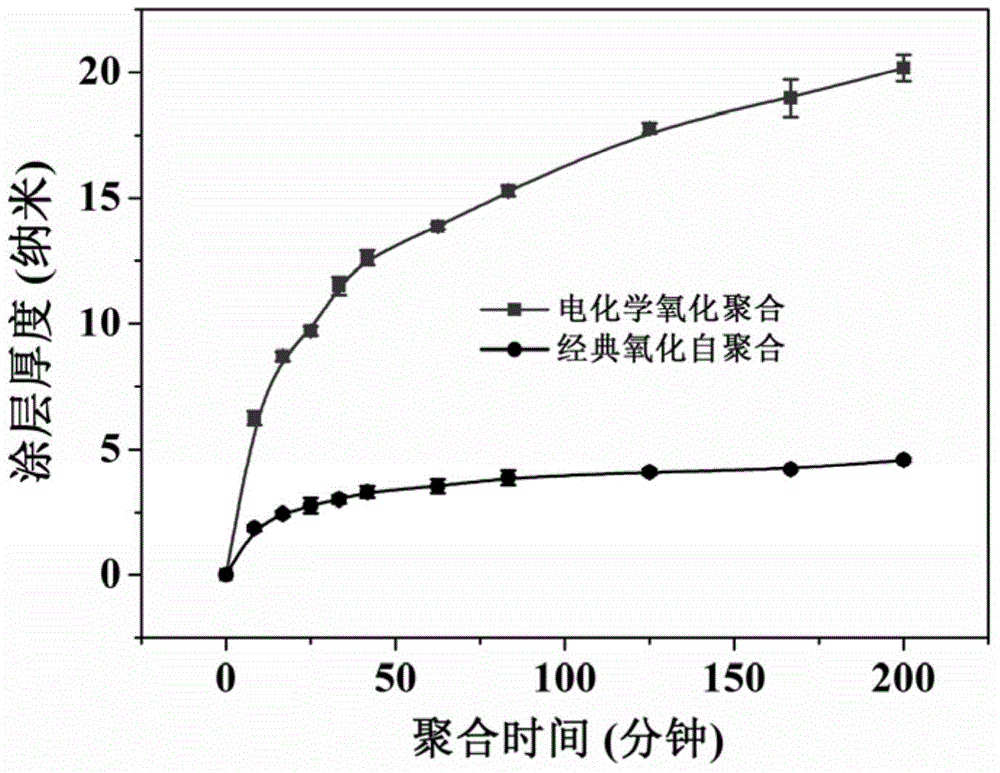

[0043] (1) Place the cleaned gold-plated silicon chip as a working electrode in tris hydrochloride buffer containing 1 mg / mL dopamine (containing 25 mM Tris, 140 mM NaCl and 3 mM KCl, pH=7.4).

[0044] The electrochemical polymerization reaction was carried out on a CHI660D electrochemical workstation, using a three-electrode system, in which the reference electrode was a 232-type saturated calomel electrode, and the counter electrode was a platinum sheet electrode. Electrochemical oxidative polymerization of dopamine was carried out by cyclic voltammetry under room temperature and nitrogen protection conditions. The selected potential scanning range was –0.5 to 0.5V, and the scanning speed was 20mV / s. After 3 hours of polymerization, the gold-plated silicon chip was taken out and deionized water was used. Rinse and dry with nitrogen gas for later use.

[0045] (2) Place polydopamine-modified gold-coated silicon wafers in 170 mg / mL silver nitrate solution and react at room tem...

Embodiment 2

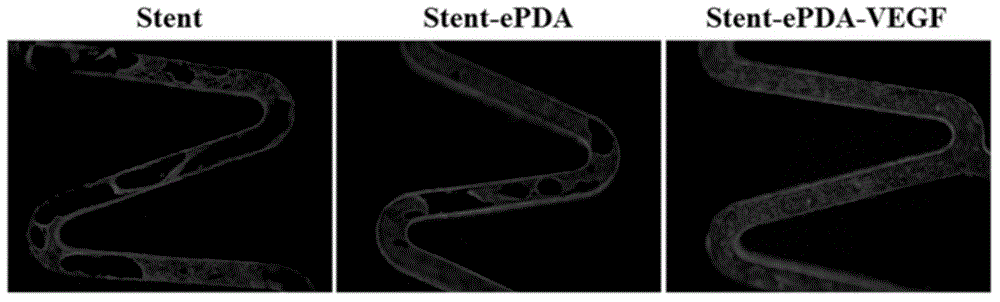

[0049] (1) A 316L stainless steel cardiovascular stent was placed as a working electrode in tris hydrochloride buffer containing 1 mg / mL dopamine (containing 25 mM Tris, 140 mM NaCl and 3 mM KCl, pH=7.4).

[0050] The electrochemical polymerization was carried out on a CHI660D electrochemical workstation, using a three-electrode system, in which the reference electrode was a 232-type saturated calomel electrode, and the counter electrode was a platinum sheet electrode. Electrochemical oxidative polymerization of dopamine was carried out by cyclic voltammetry under room temperature and nitrogen protection conditions, the selected potential scanning range was –0.5 to 0.5V, and the scanning speed was 20mV / s. After 3 hours of polymerization, the cardiovascular stent was taken out with deionized water Rinse and dry with nitrogen gas for later use.

[0051] (2) Place polydopamine-modified cardiovascular stents in Tris hydrochloride buffer (10 mM, pH=8.5) containing 500 ng / mL of vasc...

Embodiment 3

[0055] (1) Place the ITO conductive glass as a working electrode in a phosphate buffer containing 2mg / mL norepinephrine (containing 137mM NaCl, 2.7mM KCl, 10mM NaCl, 2 HPO 4 and 2mMKH 2 PO 4 , pH=7.4).

[0056] The electrochemical polymerization was carried out on a CHI660D electrochemical workstation, using a three-electrode system, in which the reference electrode was a 232-type saturated calomel electrode, and the counter electrode was a platinum sheet electrode. The electrochemical oxidative polymerization of norepinephrine was carried out by cyclic voltammetry at room temperature and under the protection of nitrogen. The selected potential scanning range was –0.3~0.8V, and the scanning speed was 10mV / s. After 3 hours of polymerization, the ITO conductive glass was taken out, rinsed with deionized water, dried with nitrogen gas, and then used for later use.

[0057] (2) Place the polynorepinephrine-modified ITO conductive glass in tris hydrochloride buffer solution (10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com