High-density electric flocculation device with slidable pole plates and use method thereof

An electro-flocculation, high-density technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high power consumption, short anode life, and easy passivation of electrodes. , to achieve the effect of improving the life of the electrode, prolonging the replacement cycle, and increasing the relative flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

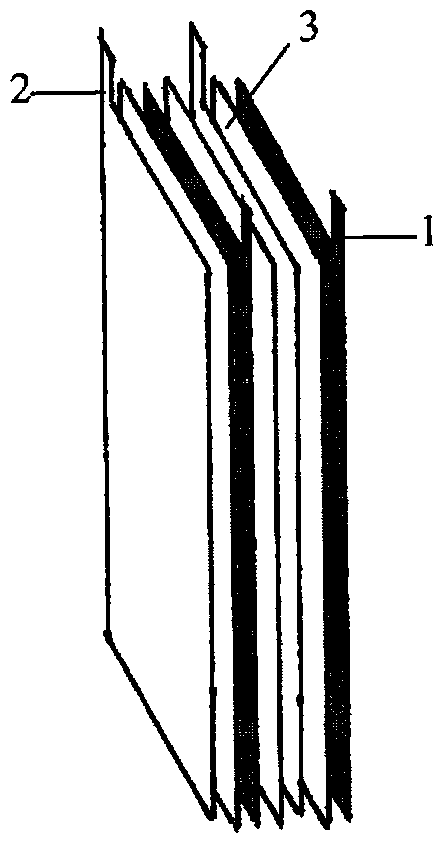

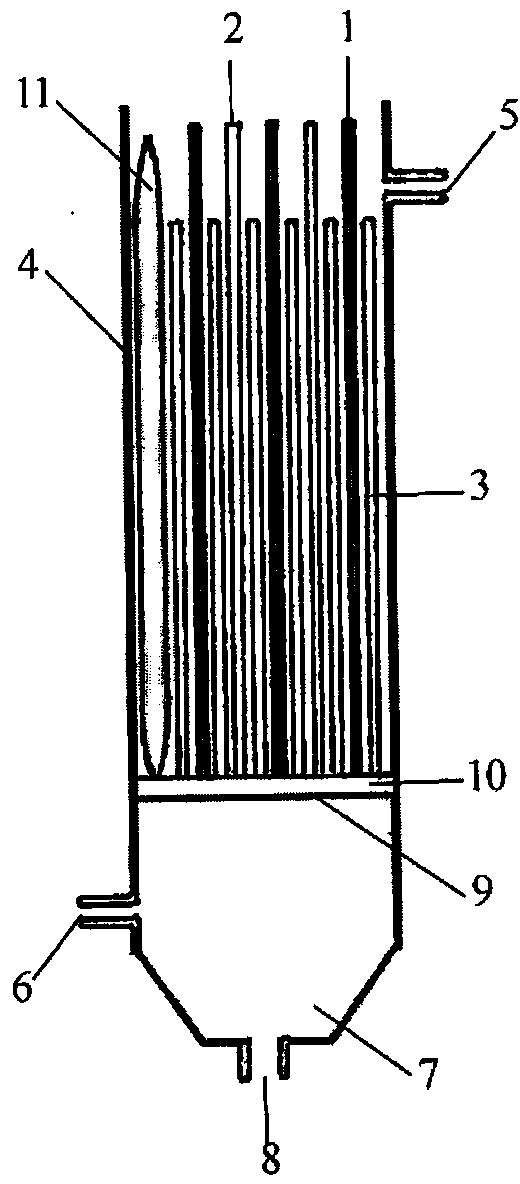

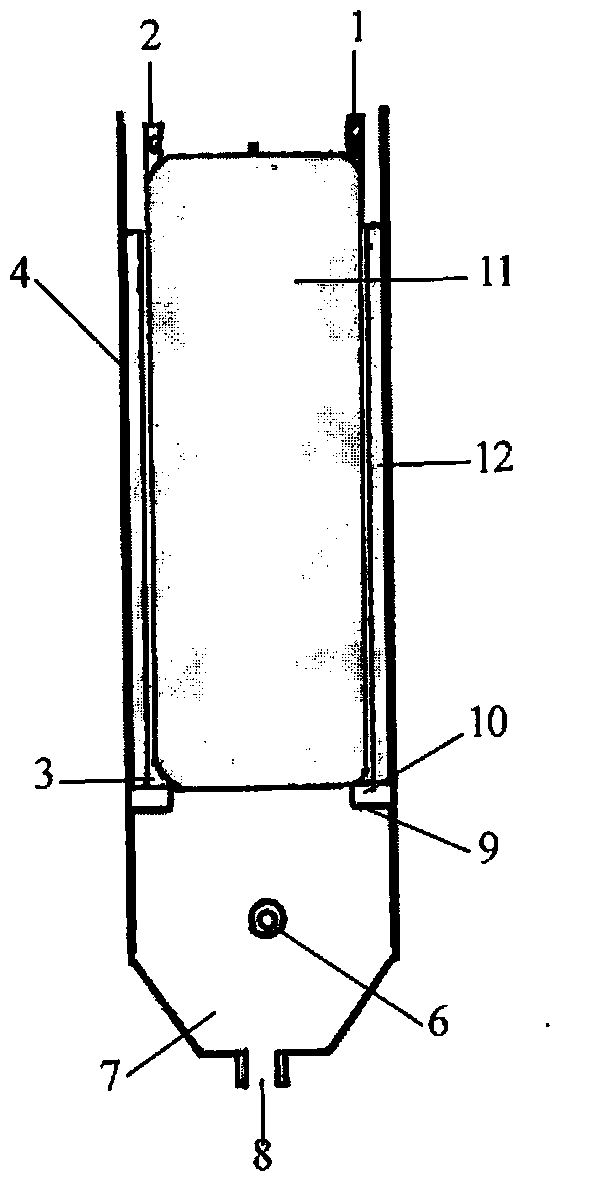

[0039] Two 65×65×600mm stainless steel square tubes are used as shells, 2mm thick carbon steel plates are used as anodes and bipolar electrodes, and 2mm thick stainless steel plates are used as cathodes to make electroflocculation devices. The volume of the device is 2L when no electrodes are installed. A traditional electrocoagulation device (device 1) is made with a shell, the distance between the plates is 6mm, and 7 plates can be installed. Another shell is made device (device 2) of the present invention, and the polar plate pitch is 1.2mm, can adorn 19 polar plates.

[0040] The original arsenic concentration of arsenic-containing wastewater in a concentrator is 22.3 mg / L, and it is treated by device 1 and device 2 respectively. The specific steps are:

[0041] After adjusting the pH value to 5 with quicklime, they enter device 1 and device 2 at a rate of 30L / hour respectively, and the working current is set to 4A. At this time, the operating voltage of device 1 is 5.2...

Embodiment 2

[0044] Two 65×65×600mm stainless steel square tubes are used as shells, 3mm thick magnesium alloy plates (brand: AZ31) are used as anodes and amphoteric electrodes, and 2mm thick stainless steel plates are used as cathodes to make a traditional electroflocculation device ( Device 3) and the electrocoagulation device (device 4) according to the present invention. The volume of the device is 2L when no electrodes are installed. The distance between the 3 pole plates of the device is 5mm, and 7 pole plates can be installed. The distance between the 4 pole plates of the device is 1.5mm, and 15 pole plates can be installed.

[0045] The zinc and cadmium in wastewater from a smelter exceeded the standard. The original zinc concentration was 44.7mg / L, the cadmium concentration was 16.9mg / L, and the pH value was 3.8. Device 3 and device 4 were used to treat it respectively. The specific steps are:

[0046] The raw water directly enters device 3 and device 4 without adjusting the pH...

Embodiment 3

[0049] Using two 110×110×600mm stainless steel square tubes as shells, 2mm thick aluminum plates (grade: 1100) as anodes and amphoteric electrodes, and 2mm thick stainless steel plates as cathodes, a traditional electroflocculation device (device 5 ) and the electrocoagulation device (device 6) of the present invention. The volume of the device is 6L when no electrodes are installed. The distance between the 5 pole plates of the device is 11mm, and 8 pole plates can be installed. The distance between the 6 pole plates of the device is 1.5mm, and 27 pole plates can be installed.

[0050] A certain electroplating wastewater containing 23.5 mg / L of copper was treated with device 5 and device 6 respectively. The specific steps are:

[0051] The raw water is adjusted to pH 6 with sodium hydroxide and then enters device 5 and device 6 for treatment. The water inflow rate is 60L / hour and the working current is 12A. At this time, the operating voltage of device 5 is 9.8V, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com