Granule sludge and biological film coupled integrated sewage treatment method and treatment device suitable for same

The technology of a sewage treatment device and a sewage treatment method is applied in the field of a granular sludge biofilm coupling integrated sewage treatment method and its treatment device, which can solve the problem that a high-speed anaerobic biological treatment system cannot solve the problem of N, P removal, N, P The removal effect is not ideal, affecting the treatment effect of the system, etc., to achieve the effect of reducing sludge discharge, compact structure and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

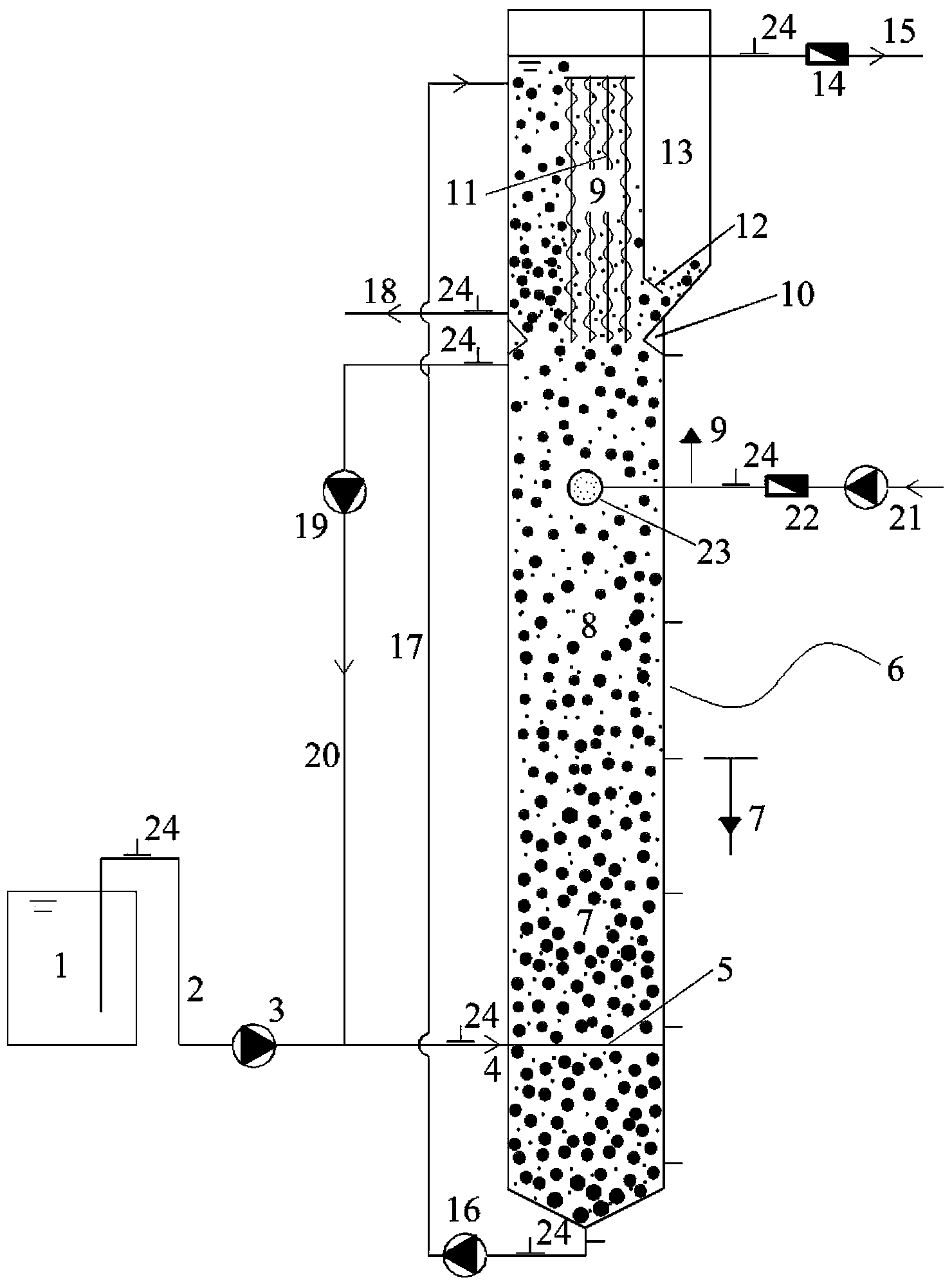

[0052] The structure of the granular sludge biofilm coupling integrated sewage treatment device is as follows: figure 1 As shown, it consists of a reactor 6 and a waste water storage tank 1.

[0053] The reactor is made of stainless steel and is divided into two parts: reaction zone (including anaerobic zone 7, anoxic zone 8 and aerobic zone 9) and clarification zone 13. Among them, the lower part of the reaction zone has an inner diameter of 100mm and a height of 1.8m; the upper part has an inner diameter of 90mm and a height of 0.6m, with a total volume of 18L; the clarification zone is a ring column with an inner diameter of 90mm and an inner diameter of the outer ring of 150mm, with a height of 0.6m and a volume of 3.5L (half one volume). The reactor is pre-corrosion-treated, and contains granular sludge, suspended sludge and biofilm for degrading pollutants in wastewater.

[0054] The waste water storage tank is used for storing sewage, and its water outlet is connected...

Embodiment 2

[0067] Take the dewatered sludge from the digestion tank of a sewage treatment plant in Taiyuan for activity recovery, mix it with a small amount of loose granular sludge (the granular sludge was originally used to treat beer wastewater, and it was submerged in water for two years without any nutrients) and inoculated into In the experimental reactor, self-prepared beer wastewater was used, and the operation was started at 35°C, and the HRT was maintained for 3.4h. The influent COD was increased from 300mg / L to 1200mg / L within a week, and the influent load was increased from 2.37kgCOD / m 3 ·d increased to 9.0kgCOD / m 3 d, Granular sludge was formed rapidly, at this time the sludge concentration reached 31.3g / L, VSS / SS reached 0.68, and the COD removal rate reached 91.7%. Then use this granular sludge to directly treat domestic sewage, while keeping the operating temperature at an ambient temperature of 11-24°C, when the influent HRT is 1.7h, and the COD concentration is 127-424m...

Embodiment 3

[0070] Take the granular sludge from the stable running coking wastewater pilot plant (COD removal rate can reach 70%-80%, ammonia nitrogen removal rate can reach 40%-50%), and inoculate it into the experimental reactor to treat coking wastewater , coking wastewater was taken from a coking plant in Taiyuan City, and the concentrations of influent COD, ammonia nitrogen, phenols, SCN and CN were 630-950mg·L -1 , 79-178mg·L -1 , 19.6-453.3mg·L -1 , 87.7-537.5mg·L -1 , 0.79-51.8mg·L -1 .

[0071] Simultaneously start the sewage backflow, sludge backflow and aeration to form an effective circulation of sewage and sludge as well as a micro-oxygen environment in an appropriate position in the reactor, and gradually form biofilm, suspended sludge and granular sludge in the reactor Coupling of aerobic zone, anoxic zone and anaerobic zone; coupling of aerobic microenvironment, anoxic microenvironment and anaerobic microenvironment. An obvious feature of this stage is: the removal of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com