Catalyst composition for ethylene gas-phase polymerization or co-polymerization, preparation and applications thereof

A gas-phase polymerization and catalyst technology, applied in the field of bimetallic silica gel carrier catalyst composition and preparation thereof, can solve the problems of narrow molecular weight distribution of polyethylene resin, difficulty in achieving complete and uniform blending of resin, affecting the final performance of resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

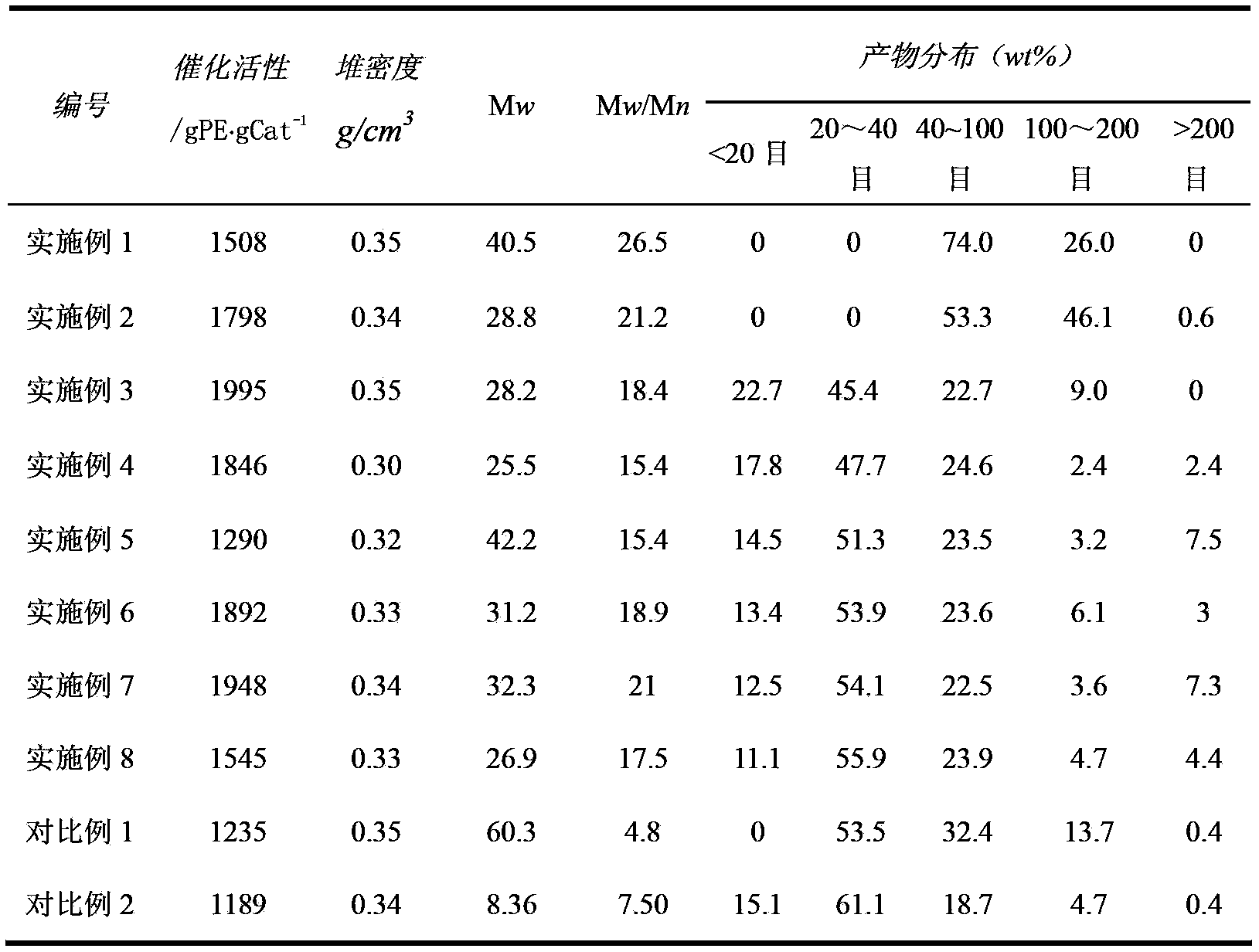

Examples

Embodiment 1

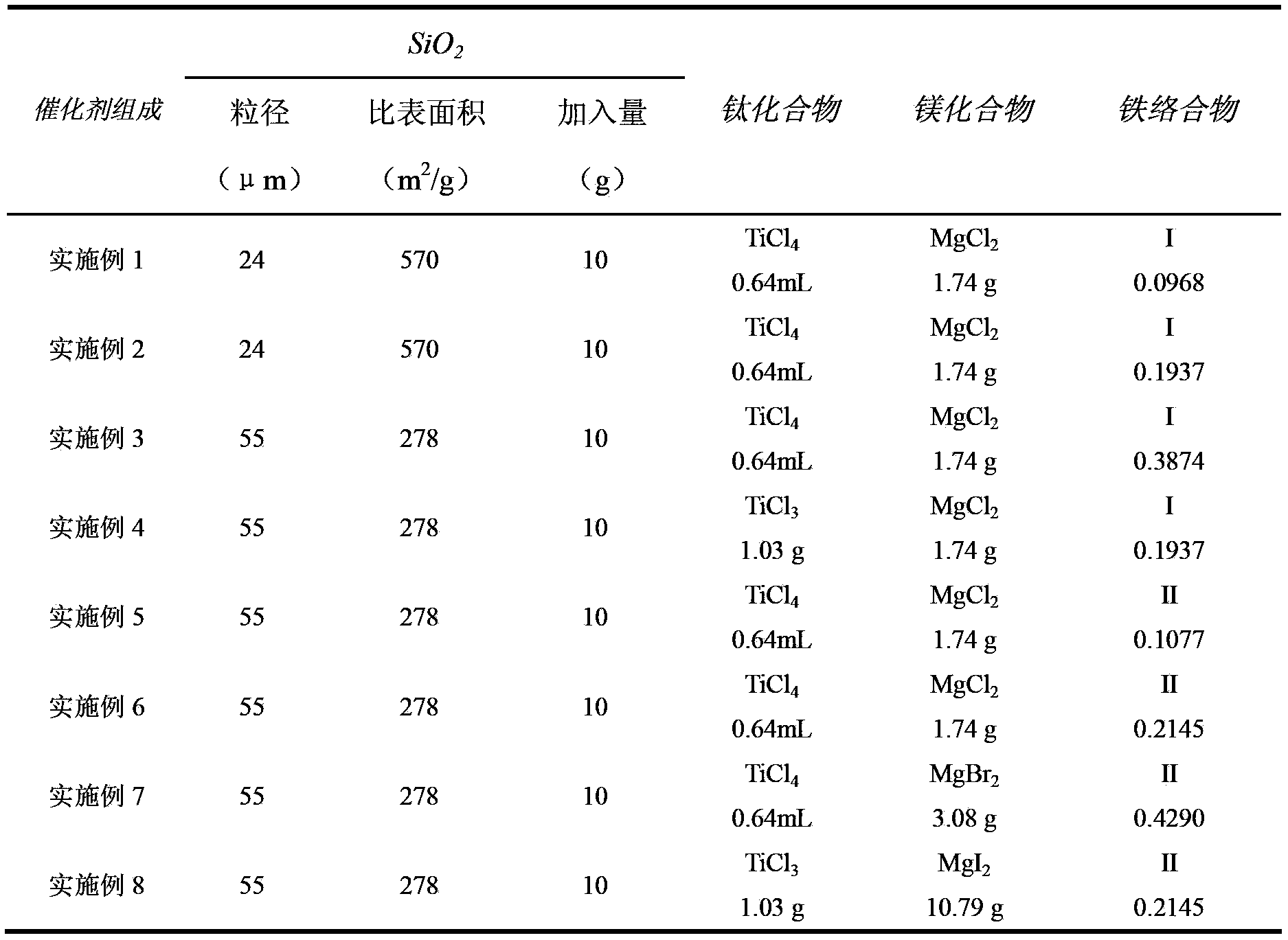

[0046] Preparation of bimetallic catalyst composition:

[0047] (1) Weigh 20g of spherical silica gel (produced by Grace Company in the United States, with an average particle size of 45μm and a specific surface area of 350m 2 / g), put silicon dioxide in a gas-phase fluidized bed activator, blow and fluidize it with anhydrous and oxygen-free nitrogen, gradually raise the temperature to 600°C, and dehydrate at constant temperature for 6 hours to obtain dehydrated silicon dioxide.

[0048] (2) Add 100mL of isopentane to a reaction flask with a stirrer under nitrogen protection, add 10g of silica gel after thermal activation treatment in step (1) and 5.6mL of AlEt with a concentration of 1mmol / mL 3 Add the hexane solution, react at 20-30°C for 1 hour, heat to evaporate the alkane solvent, and obtain fluid activated silica.

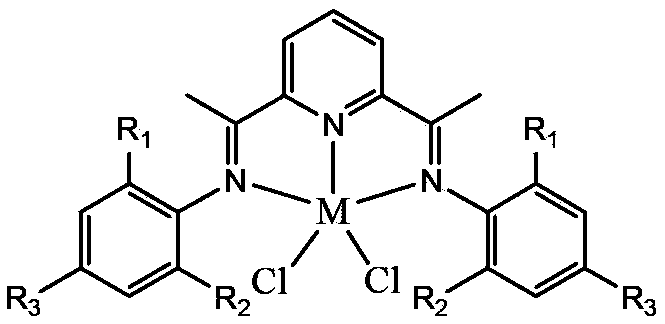

[0049] (3) In another reaction flask with a stirrer, add 0.64mL TiCl 4 , 2,6-bis[1-(2,6-dimethylbenimine)ethyl]pyridine ferric dichloride 0.0968g, 1.74g ...

Embodiment 2

[0055] Preparation of bimetallic catalyst composition:

[0056] (1) Weigh about 20g of spherical silica gel (produced by Grace Company in the United States, with an average particle size of 45μm and a specific surface area of 350m 2 / g), put silicon dioxide in a gas-phase fluidized bed activator, blow and fluidize it with anhydrous and oxygen-free nitrogen, gradually raise the temperature to 600°C, and dehydrate at constant temperature for 4 hours to obtain dehydrated silicon dioxide.

[0057] (2) Add 100mL of isopentane to a reaction flask with a stirrer under nitrogen protection, add 10g of silica gel after thermal activation treatment in step (1) and 5.6mL of AlEt with a concentration of 1mmol / mL 3 Add the hexane solution, react at 20-30°C for 1 hour, heat to evaporate the alkane solvent, and obtain fluid activated silica.

[0058] (3) In another reaction flask with a stirrer, add 0.64mL TiCl 4 , 2,6-bis[1-(2,6-dimethylbenimine)ethyl]pyridine ferric dichloride 0.1937g, ...

Embodiment 3

[0064] Preparation of catalyst composition

[0065] (1) Weigh about 20g of spherical silica gel (produced by Grace Company in the United States, with an average particle size of 55μm and a specific surface area of 278m 2 / g), put silicon dioxide in a gas-phase fluidized bed activator, blow and fluidize it with anhydrous and oxygen-free nitrogen, gradually raise the temperature to 600°C, and dehydrate at constant temperature for 10 hours to obtain dehydrated silicon dioxide.

[0066] (2) Add 100mL of isopentane to a reaction flask with a stirrer under nitrogen protection, add 10g of silica gel after thermal activation treatment in step (1) and 5.6mL of AlEt with a concentration of 1mmol / mL 3 Add the hexane solution, react at 20-30°C for 1 hour, heat to evaporate the alkane solvent, and obtain fluid activated silica.

[0067] (3) In another reaction flask with a stirrer, add 1.74g MgCl 2 , 2,6-bis[1-(2,6-dimethylbenimine)ethyl]pyridine ferric dichloride 0.3874g, 0.64mL TiCl 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com