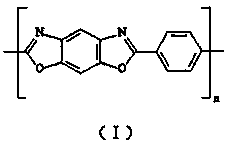

Preparation method of PBO

A section and reaction technology, applied in the new preparation field of PBO (poly-p-phenylene benzobisoxazole), can solve the problems of difficult transportation, high viscosity of the system, long time, etc., and achieve strong controllability and improved The effect of simple and convenient production scale and process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 6.42g (0.03mol) 4,6-diamino-1,3-resorcinol hydrochloride, 152g polyphosphoric acid, 0.1g stannous chloride dihydrate to a volume of 500ml under nitrogen atmosphere In the batching degassing tank with stirring paddle, temperature control and vacuum system, maintain the system temperature at 120°C to fully stir and degas, then add 4.99g (0.03mol) terephthalic acid and 40g phosphorus pentoxide to the system , so that the raw materials are fully dispersed and mixed evenly. Then turn on the precise metering pump under the raw material preparation degassing tank, and continuously send the prepared polymerization raw materials into the capillary-type microfluidic polymerization reaction tube with a diameter of Φ2~3mm under heating for polymerization reaction. The microfluidic polymerization reaction tubes can be arranged in a grid pattern, in a spiral coil arrangement, etc., so as to be heated by a high-temperature bath. These microfluidic polymerization reaction tube...

Embodiment 2

[0025] Add 102g (0.3mol) 4,6-diaminoresorcinol phosphate, 1520g polyphosphoric acid, 1.5g stannous chloride dihydrate to a volume of 5000ml with stirring paddle, temperature In the ingredient degassing tank of the control and vacuum system, keep the system temperature at 90°C and stir thoroughly for 2 hours, then add 49.9g (0.3mol) terephthalic acid and 40g phosphorus pentoxide to the system to fully disperse and mix the raw materials evenly. Then turn on the precise metering pump under the raw material preparation degassing tank, and continuously send the prepared polymerization raw materials into the capillary-type microfluidic polymerization reaction tube with a diameter of Φ7~8mm under heating for polymerization reaction. The microfluidic polymerization reaction tubes can be arranged in a grid pattern, in a spiral coil arrangement, etc., so as to be heated by a high-temperature bath. These microfluidic polymerization reaction tubes can be divided into four reaction tempera...

Embodiment 3

[0027] Refer to the method of preparing DAR-TA salt in Example 1 in Patent No. 201310735715.7: Dissolve 3.20g of 4,6-diaminoresorcinol hydrochloride (0.015mol) in deionized aqueous solution containing 0.01g of stannous chloride 2.50g of terephthalic acid (0.015mol) was dissolved in 300ml of NaOH solution, and gradually added dropwise to the aforementioned aqueous solution of 4,6-diaminoresorcinol hydrochloride under nitrogen protection. After the dropwise addition was completed, the temperature was raised to 90° C. for 10 minutes to react. After the white solid was precipitated, it was filtered and washed under a nitrogen atmosphere, and then dried in a vacuum oven at 60°C for 48 hours to obtain 4,6-diaminoresorcinol-terephthalate (DAR-TA complex salt), and the samples were taken out and stored under vacuum.

[0028] Add 15.22g of polyphosphoric acid, 6.35g of phosphorus pentasulfide, and 0.02g of tin powder into the reaction kettle. After mixing and stirring, replace the air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com