Preparation method of tin antimony oxide (ATO) water-based nano-dispersion slurry

A water-based and nano-dispersion technology of antimony tin oxide, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of increasing the viscosity of the slurry, hindering the contact between particles, and reducing the antistatic performance of ATO. The effect of maintaining the characteristics and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

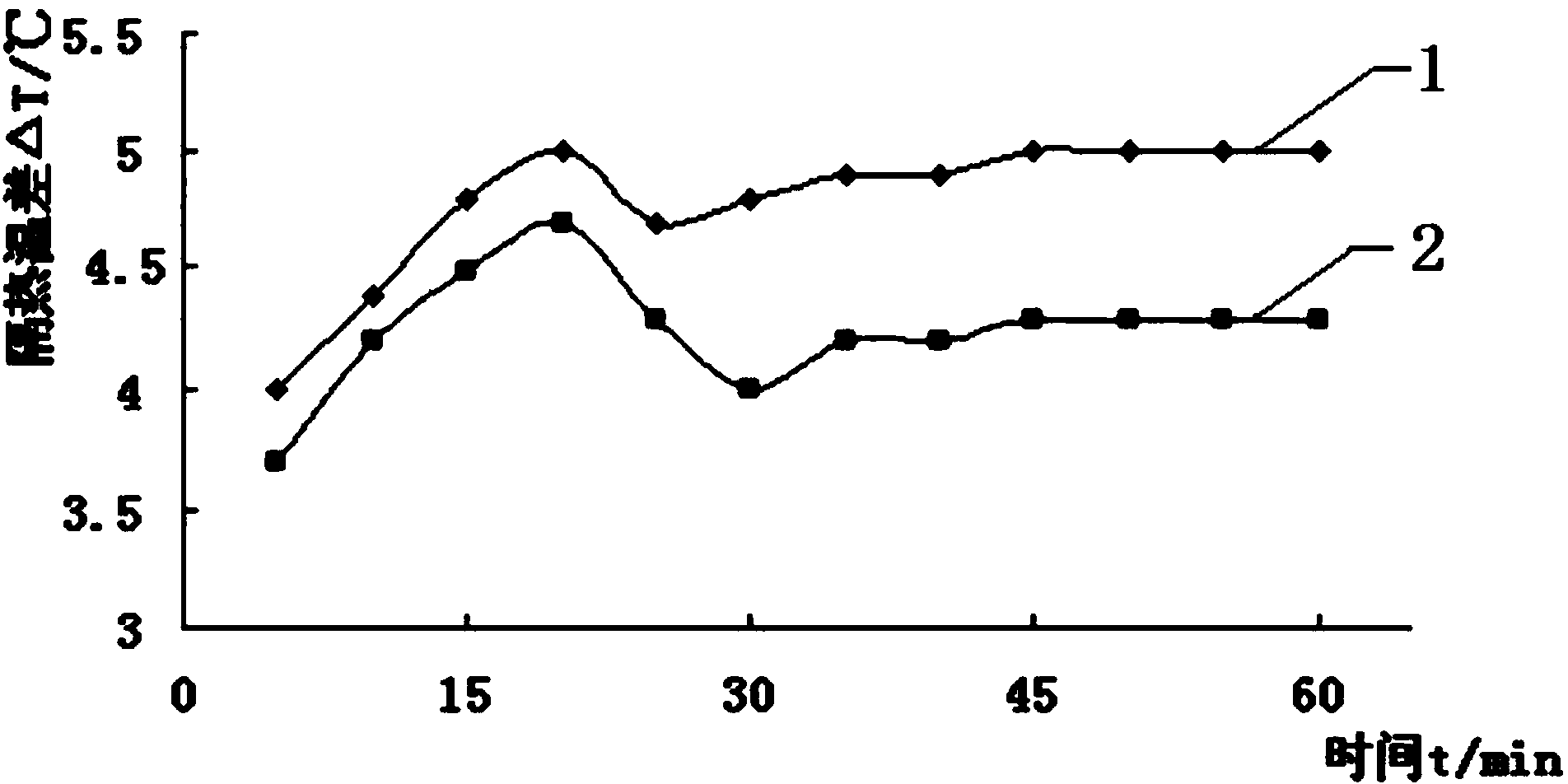

Image

Examples

Embodiment 1

[0030] Take 82.11g SnCl 4 and 3.91 g SbCl 3 (SnO 2 :Sb 2 o 3 =95:5) was dissolved in 300ml 2mol / L hydrochloric acid solution (to prevent the metal salts of tin and antimony from being hydrolyzed during the dissolution process), add ammonia water under stirring, control the reaction temperature at 5°C, react until the precipitation is complete, and finally control the pH =7.0. Then filter, wash with deionized water, dehydrate with ethanol, and dry in vacuum at 40°C for 6.0h to obtain the ATO precursor. Mix ATO precursor with 0.1mol / L H 2 SO 4 The solutions were mixed in a mass ratio of 1:2 (H 2 SO 4 The dosage is about 2% by weight of ATO), dispersed at high speed for 30 minutes, spray-dried (inlet air temperature 180°C, outlet temperature 60°C), after drying, the powder was calcined at 400°C for 5.0h to obtain modified ATO nanopowder.

[0031] The modified ATO nanopowder and deionized water are formulated into ATO slurry at a mass concentration of 10%, mixed evenly, a...

Embodiment 2

[0033] Take 82.11g SnCl 4 and 3.91 g SbCl 3 (SnO 2 :Sb 2 o 3 =95:5) was dissolved in 300ml 2mol / L hydrochloric acid solution, ammonia water was added under stirring, the reaction temperature was controlled at 0°C, and the reaction was carried out until the precipitation was complete, and finally the pH was controlled to be 7.0. Then filter, wash with deionized water, dehydrate with ethanol, and vacuum dry at 80° C. for 3.0 h to obtain the ATO precursor. Mix ATO precursor with 0.06mol / L H 3 PO 4 The solution was mixed in a mass ratio of 1:3.4 ((H 3 PO 4 The dosage is about 2% of the weight of ATO), dispersed at high speed for 30 minutes, and dried under vacuum stirring (drying temperature 65° C.). After drying, the powder was calcined at 600° C. for 3.0 hours to obtain the modified ATO nanopowder.

[0034]Prepare the modified ATO nanopowder and deionized water into ATO slurry at a mass concentration of 25%, mix well, grind and disperse in a sand mill, adjust the pH valu...

Embodiment 3

[0036] Take 77.79gSnCl 4 and 9.12gSb 2 (SO 4 ) 3 (SnO 2 :Sb 2 o 3 =90:10) was dissolved in 300ml of 2mol / L sulfuric acid solution, ammonia water was added under stirring, the reaction temperature was controlled at 30°C, and the reaction was carried out until the precipitation was complete, and finally the pH was controlled to be 7.0. Then filter, wash with deionized water, dehydrate with ethanol, and vacuum dry at 90° C. for 2.0 h to obtain the ATO precursor. Mix ATO precursor with 0.02mol / L H 2 SO 4 The solution was mixed at a mass ratio of 1:10.2 (H 2 SO 4 The dosage is about 2% of the weight of ATO), dispersed at high speed for 30 minutes, spray-dried (inlet air temperature 180°C, outlet temperature 80°C), after drying, the powder was calcined at 750°C for 1.0h to obtain modified ATO nanopowder.

[0037] The modified ATO nanopowder and deionized water are formulated into ATO slurry at a mass concentration of 40%, mixed evenly, and ground and dispersed in a sand mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com