Electrochromic device and manufacturing method thereof

A technology of electrochromic devices and electrochromic layers, which is applied in instruments, nonlinear optics, optics, etc., can solve the problems of high production costs, achieve the effects of reduced production costs, good compatibility, and simple and easy production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

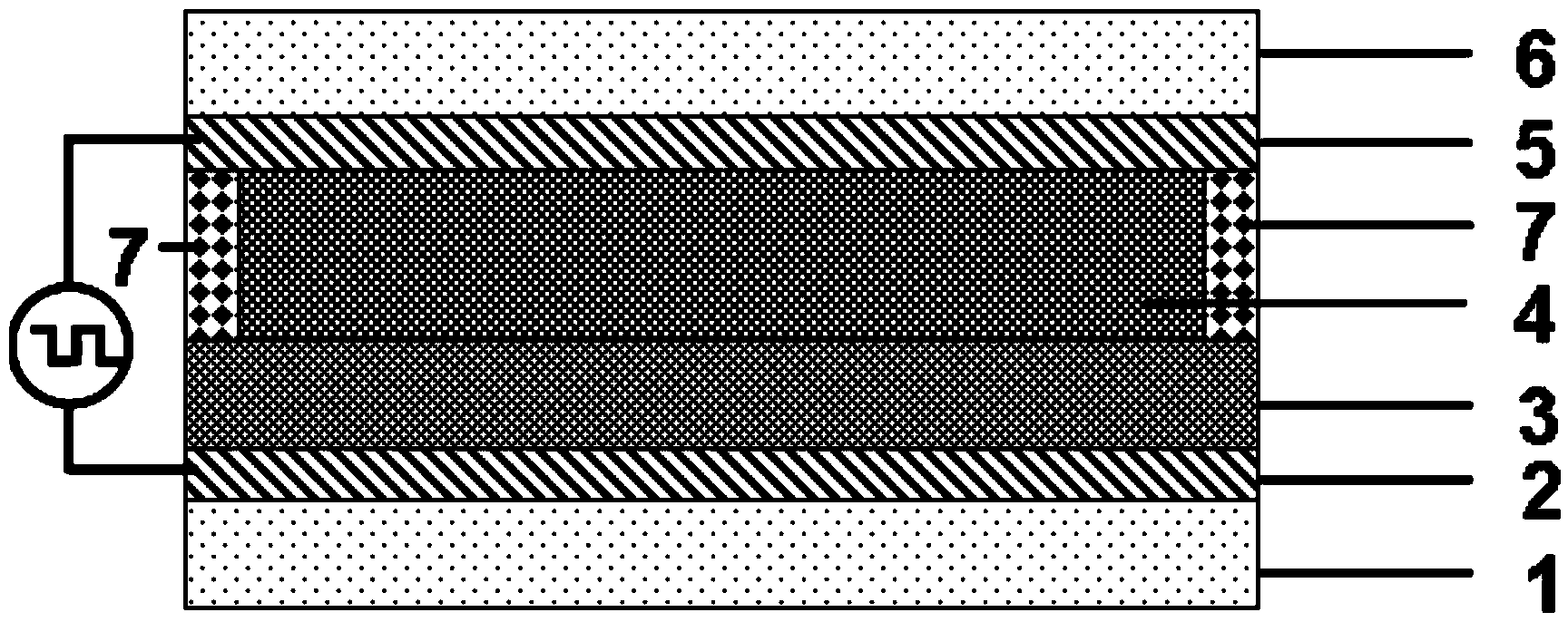

[0029] Such as figure 1 The single-layer electrochromic device of the present invention is shown, wherein the first transparent substrate 1 is an ordinary glass sheet and is arranged on the bottom layer; the first transparent conductive layer 2 is an indium zinc oxide (IZO) film, communicated with an external power supply, and serves as a cathode The electrode is arranged on the top of the first transparent substrate 1; the first electrochromic layer 3 is a molybdenum-doped vanadium pentoxide film, which is arranged on the top of the first transparent conductive layer 2; the electrolyte layer 4 is filled with LiClO 4 Propylene carbonate silica (SiO 2 ) transparent nanoparticle film as a solid electrolyte; the second transparent substrate 6 is an ordinary glass sheet; the second transparent conductive layer 5 is an indium zinc oxide film, which is communicated with an external power supply as an anode electrode; the epoxy resin 7 binds the electrolyte layer 4 Both sides are wr...

Embodiment 2

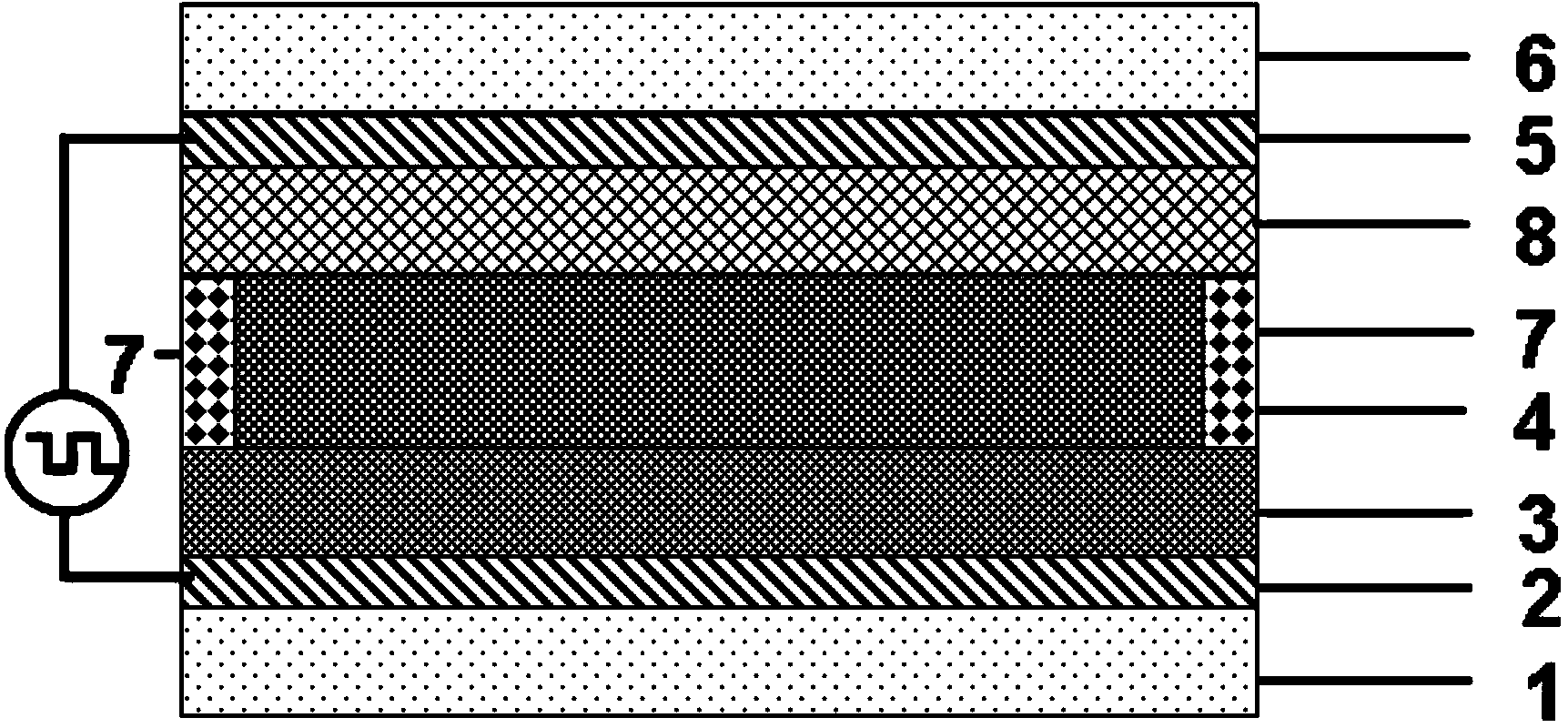

[0039] Such as figure 2 The electrochromic device of the present invention is shown, wherein the first transparent substrate 1 is arranged on the bottom layer for common glass sheets; the first transparent conductive layer 2 is an indium tin oxide (ITO) film, communicated with an external power supply, as a cathode electrode, It is arranged on the top of the first transparent substrate 1; the first electrochromic layer 3 is a molybdenum-doped vanadium pentoxide film, which is used as a cathodic color-changing layer, and is arranged on the top of the first transparent conductive layer 2; the electrolyte layer 4 is filled with LiPF 6 Silicon dioxide polysilsesquioxane (SiO 2 ) transparent nanoparticle film as a solid electrolyte; the second transparent substrate 6 is an ordinary glass sheet; the second transparent conductive layer 5 is an indium tin oxide (ITO) film, which is communicated with an external power supply as an anode electrode; the second electrochromic Layer 8 is...

Embodiment 3

[0053] Such as figure 2 The electrochromic device of the present invention is shown, wherein the first transparent substrate 1 is arranged on the bottom layer for common glass sheets; the first transparent conductive layer 2 is an indium tin oxide (ITO) film, communicated with an external power supply, as a cathode electrode, It is arranged on the top of the first transparent substrate 1; the first electrochromic layer 3 is a molybdenum-doped vanadium pentoxide film, which is used as a cathodic color-changing layer, and is arranged on the top of the first transparent conductive layer 2; the electrolyte layer 4 is filled with CH 5 Silicon dioxide (SiO 2 ) transparent nanoparticle film as a solid electrolyte; the second transparent substrate 6 is an ordinary glass sheet; the second transparent conductive layer 5 is an indium tin oxide (ITO) film, which is communicated with an external power supply as an anode electrode; the second electrochromic Layer 8 is tungsten oxide (WO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com