Corrosion and scale inhibition fountain solution and preparation method thereof

A technology of corrosion and scale inhibition and dampening solution, applied in the field of printing dampening solution, can solve the problems of contamination and other problems, and achieve the effect of maintaining equipment, reducing dirt, and reducing paper material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Preparation of fountain solution

[0020] A corrosion and scale inhibiting dampening solution, prepared from the following components by weight (kg): sucrose ester 8, liquid paraffin 1.5, lauryl amidopropyl hydroxysultaine 6, alkyl diphenyl ether disulfone Sodium acid 5, alkyl dimethyl amine oxide 1, zinc sulfate 2, sulfaguanidine 1.5, polyaspartic acid 1, polyepoxysuccinic acid 1.5, isothiazolone 0.8, sodium lactate 1.5, additive 8, water 40 ;

[0021] Among them, the auxiliary agent is made of the following raw materials by weight (kg): glycerin 7, polyethylene glycol 6, glycine 1, citric acid 2, oleic acid 1.5, clove oil 0.5, rhamnose 0.5, tea polyphenol 0.5, carbonic acid Sodium hydrogen 2, sodium citrate 18, Tween 80 3, water 40; first dissolve citric acid and sodium citrate in water, heat to 50-60°C, then add glycerin, polyethylene glycol, clove oil, oleic acid and sodium bicarbonate, stirred for 15 minutes, cooled to room temperature, added the re...

Embodiment 2

[0026] Embodiment 2: the test of fountain solution performance

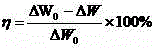

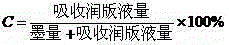

[0027] 1. Ink emulsification rate

[0028] Fountain solution mainly affects the balance performance of water and ink in the printing process, and the emulsification rate of ink is an important parameter. The nature of the fountain solution has an important influence on the ink emulsification rate. According to the principle of offset printing, it is feasible for the ink emulsification rate to be lower than 26% during the offset printing process.

[0029] Determination of ink emulsification rate C: by weight method.

[0030] Dilute the dampening solution described in Example 1 to 3% with distilled water, add 50 g of black ink and 50 g of the diluted dampening solution to the container at one time, stir at 100 r / min for 1 hour and then let it stand for 10 minutes, remove the unabsorbed dampening solution The liquid and the ink are separated in layers, and the emulsification rate of the ink is calculated accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com