Power type heat pipe waste heat boiler device

A waste heat boiler and heat pipe type technology, which is applied in the field of power type heat pipe type waste heat boiler installations, can solve the problems of inability to accurately control the flue gas outlet temperature, high exhaust gas temperature, slow start-up, etc., achieves small irreversible thermodynamic losses, and avoids low temperature acidity. Effects of corrosion, efficient energy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

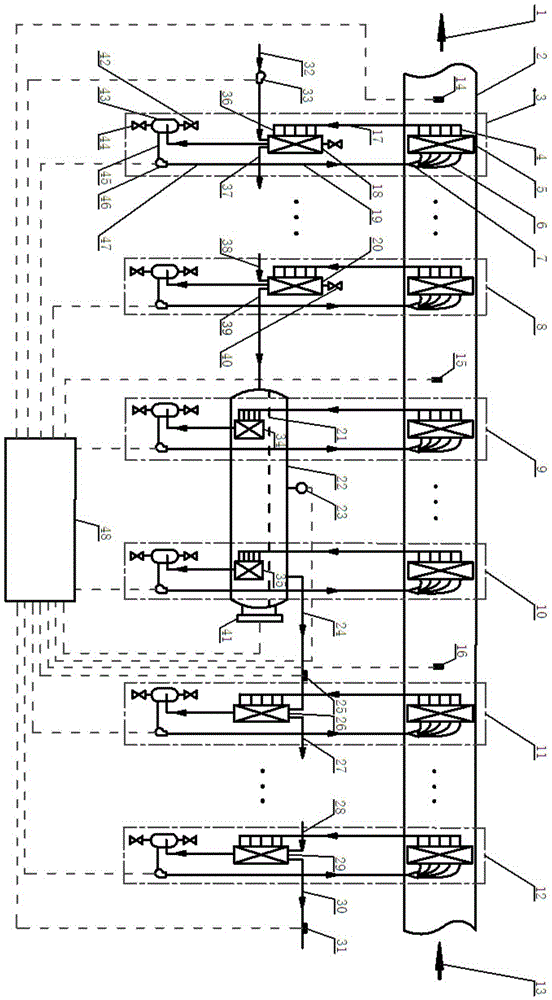

[0018] The main structure of the power type heat pipe waste heat boiler device described in this embodiment includes a flue gas outlet 1, a flue 2, a heat pipe circulation 3 for the first economizer, a gas-liquid collection pipe 4, a heat pipe evaporator 5, and a liquid equalizing pipe 6 , liquid separator 7, heat pipe circulation for the nth economizer 8, heat pipe circulation for the first boiling section 9, heat pipe circulation for the mth boiling section 10, heat pipe circulation for the first superheater 11, and kth superheater Heat pipe circulation 12, flue gas inlet 13, temperature sensor after economizer 14, temperature sensor after boiling section 15, temperature sensor after superheater 16, gas-liquid two-phase flow main pipe 17, heat pipe circulation condenser for the first economizer 18. Liquid supply main pipe 19, heat pipe circulation condenser 20 for the nth economizer, steam drum water level line 21, steam drum 22, steam drum pressure indicator sensor 23, satur...

Embodiment 2

[0026] In this embodiment, the start-up and operation process of producing superheated steam from waste heat of flue gas is as follows: figure 1 After the structural principle shown in the combination is installed into a power heat pipe waste heat boiler system device, the inside of each heat pipe circulation pipeline is blown and cleaned first, and then the inside of each heat pipe circulation pipeline is subjected to physical and chemical passivation treatment. After the treatment is completed , to evacuate n economizer heat pipe cycles, m boiling section heat pipe cycles and k superheater heat pipe cycles. The flue gas temperature, the flue gas temperature after the boiling section, the flue gas temperature after the superheater, and the position of the water level line of the steam drum are set to specific values. The subsystem will compare the actual value of the control parameters such as the flue gas temperature after the economizer with the set specific value, and star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com