Halogenn-free flame retardant polyurethane sealant and preparation method thereof

A polyurethane sealant and sealant technology, applied in the field of sealant, can solve the problems of red phosphorus explosion, easy precipitation, and low flame retardant efficiency of flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Mix 1000g of PPG with a molecular weight of 2000 and 200g of polyoxyglycerol with a molecular weight of 5000, remove water under low vacuum at 120°C for 1 hour, cool down to 45°C, add 330g of crude MDI and 0.007% of the above mixture by weight Stannous octoate was reacted for 4 hours, and after the residual isocyanate content reached the theoretical value, the temperature was lowered to obtain a polyurethane prepolymer.

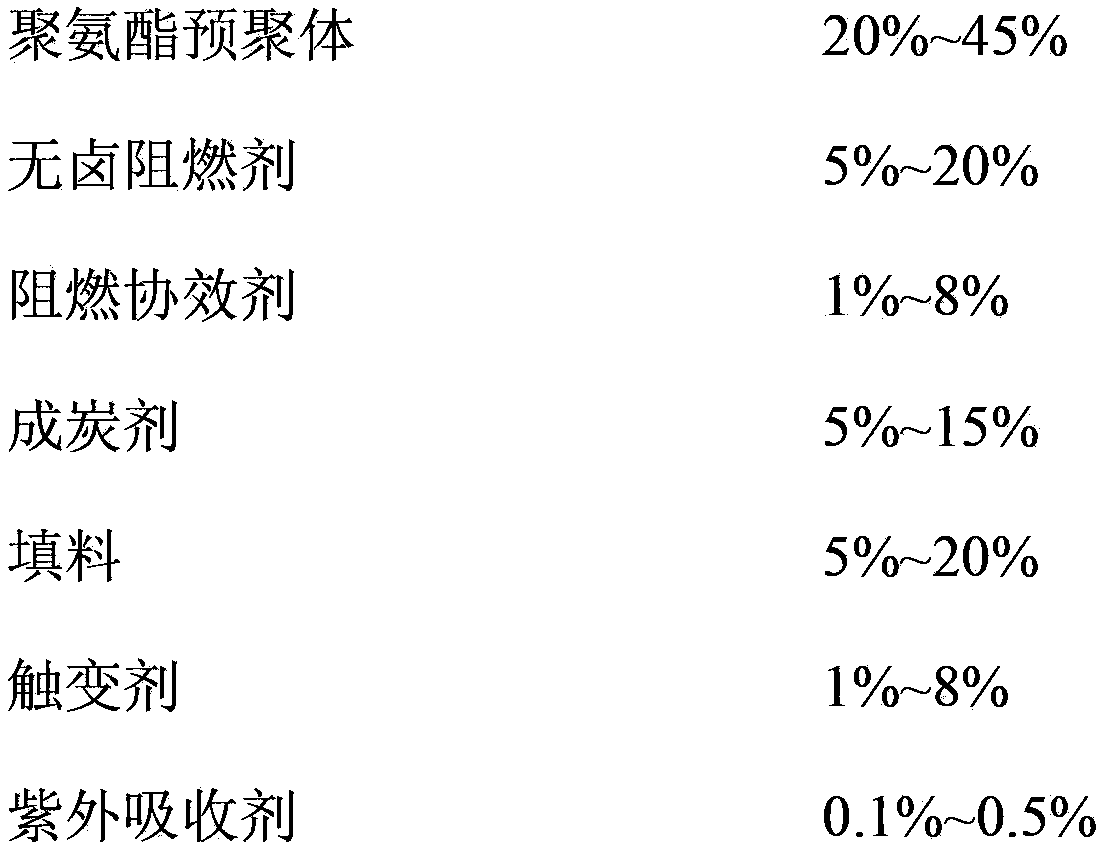

[0030] (2) Prepare raw materials according to the following formula

[0031]

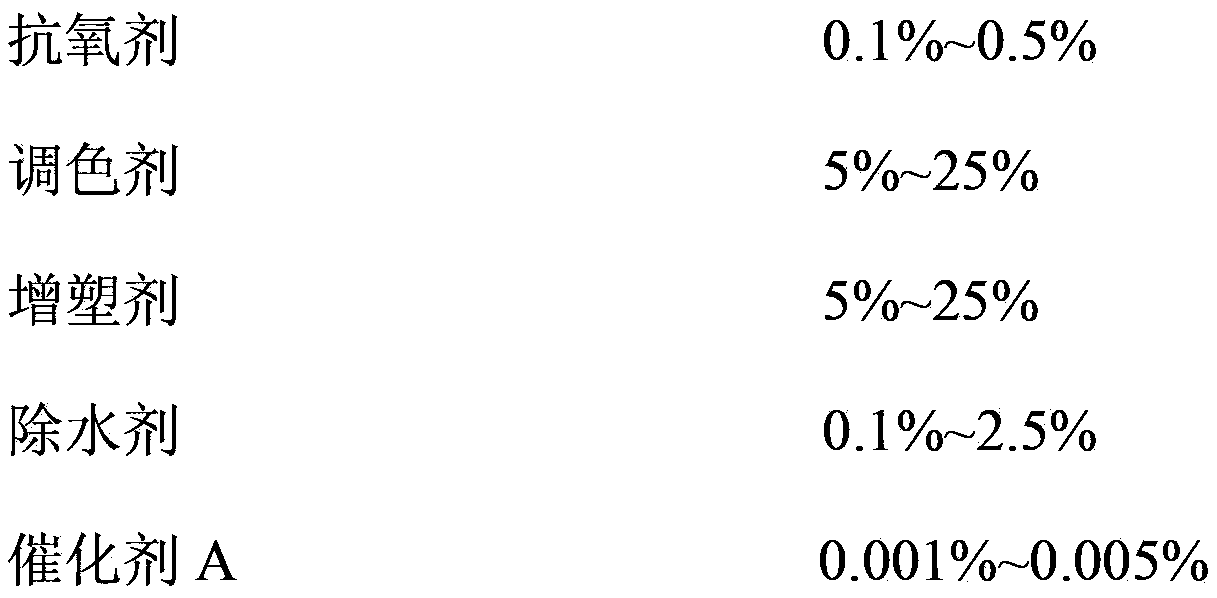

[0032]

[0033] (3) According to the above formula, mix 200g of polyurethane prepolymer with 50g of BDP, 50g of TRIMER, 30g of hydrotalcite, 30g of PER, 30g of ethylene glycol, 150g of 10μm light calcium calcium, 20g of hydrogenated castor oil, 24g of UV6224g, antioxidant Add 10101g of agent, 240g of carbon black and 180g of chlorinated paraffin oil into a double planetary mixer with a high-speed dispersing head, stir and mix it at 45°C and a low vacuum of less tha...

Embodiment example 2

[0035] (1) Mix 1000g of PPG with a molecular weight of 3000 and 300g of polyoxyglycerol with a molecular weight of 5000, remove water under low vacuum at 140°C for 1 hour, cool down to 45°C, add 200g of TDI and 0.0001% of the above mixture by weight of dilaurel Dibutyltin acid, reacted for 3 hours, and after the residual isocyanate content reached the theoretical value, the temperature was lowered to obtain a polyurethane prepolymer.

[0036] (2) Prepare raw materials according to the following formula

[0037]

[0038]

[0039](3) According to the above formula, mix 220g of polyurethane prepolymer with 20g of MEL, 40g of APP, 20g of zinc borate, 110g of ultrafine pentaerythritol, 160g of 10μm heavy calcium, 30g of hydrogenated castor oil, UV3274g, antioxidant 10761g, Add 220g of carbon black and DOP170g into a double planetary mixer with a high-speed dispersing head, stir and mix it at 35°C and a low vacuum of less than 2kpa for 2h, and then add PTSI8g and BDMAEE0. 02g...

Embodiment example 3

[0041] (1) Mix 800g of PPG with a molecular weight of 2000 and 250g of polyoxyglycerol with a molecular weight of 6000, remove water under low vacuum at 120°C for 1 hour, cool down to 55°C, add 180g of MDI and 0.005% of the above mixture by weight. tin, react for 5 hours, and after the residual isocyanate content reaches the theoretical value, the temperature is lowered to obtain a polyurethane prepolymer.

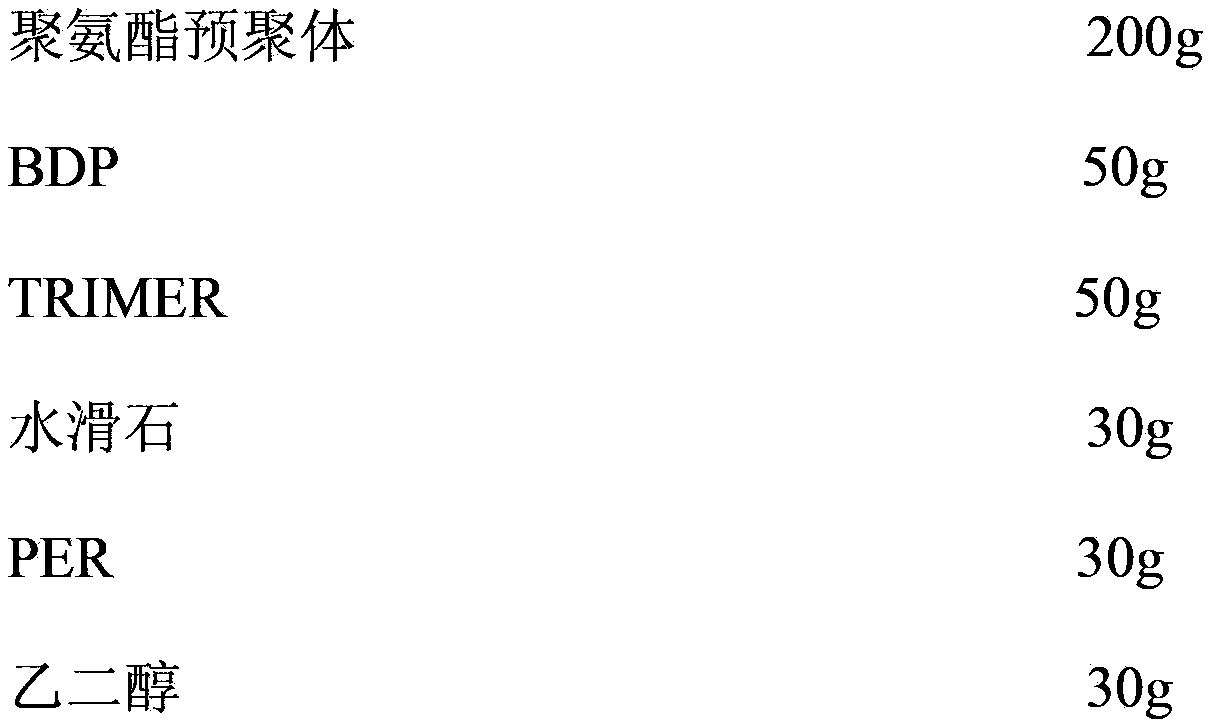

[0042] (2) Prepare raw materials according to the following formula

[0043]

[0044] (3) According to the above formula, mix 320g of polyurethane prepolymer with MEL30g, RDP50g, ammonium octamolybdate 10g, EG60g, 5μm kaolin 60g, fumed silica 10g, UV5315g, antioxidant 10102g, carbon Add 160g of black and 200g of DIDP into a double planetary mixer with a high-speed dispersing head, stir and mix it at 45°C and a low vacuum of less than 2kpa for 1.5h, then add 1g of VOS and 0.01g of DMDEE under the protection of air or high-purity nitrogen , Stir and disperse for 0.3h, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com