A treatment method for white mud industrial waste residue in pulp mill

A technology of industrial waste slag and treatment method, applied in the direction of solid waste removal, etc., can solve the problems of environmental pollution, high water content, and inability to directly comprehensively utilize, etc., and achieve significant economic benefits and stable content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

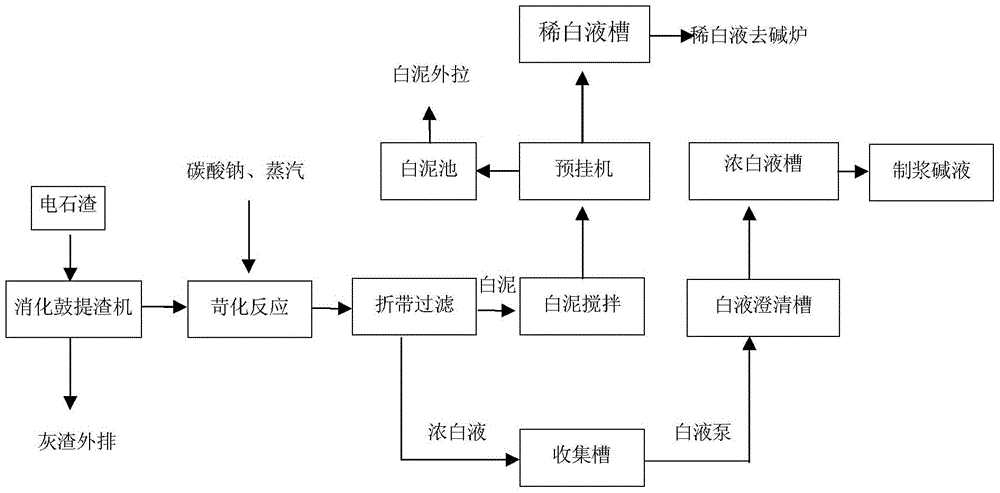

Image

Examples

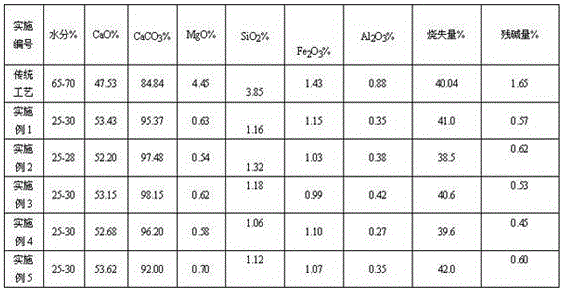

Embodiment 1

[0026] The sources of raw materials for this implementation are as follows:

[0027] White mud is the industrial waste discharged from the alkali recovery section of the paper mill.

[0028] Carbide slag is the industrial waste produced after the hydrolysis of calcium carbide to obtain acetylene gas, and its Ca(OH) 2 The content is 93%-95%.

[0029] Industrial wastewater is weakly acidic wastewater (containing a small amount of sulfuric acid) discharged from pulp and paper mills.

[0030] The calcium carbide slag is sent to the digestion drum slag extractor to be mixed with Na 2 CO 3 A causticization reaction occurs. After the reaction is completed, the product is placed on the belt folding machine and washed with industrial wastewater, so that the NaOH remaining in the reaction product enters the collection tank. The water content of the washed reaction product is kept at about 70%. The reaction after washing After the product and white mud are evenly stirred, the reaction...

Embodiment 2

[0033] The sources of raw materials for this implementation are as follows:

[0034] White mud is industrial waste discharged from pulp mills.

[0035] Carbide slag is the industrial waste produced after the hydrolysis of calcium carbide to obtain acetylene gas, and its Ca(OH) 2 The content is 90%-93%.

[0036] Industrial wastewater is weakly acidic wastewater discharged from pulp and paper mills.

[0037] The calcium carbide slag is sent to the digestion drum slag extractor to be mixed with Na 2 CO 3 A causticization reaction occurs. After the reaction is completed, the product is placed on a belt folding machine and washed with industrial wastewater, so that the NaOH remaining in the reaction product enters the collection tank. The water content of the washed reaction product is kept at about 65%. The reaction after washing After the product and white mud are evenly stirred, the reaction product and white mud are mixed and stirred according to the volume ratio of 1L:2.5...

Embodiment 3

[0040] The sources of raw materials for this implementation are as follows:

[0041] White mud is industrial waste discharged from paper mills.

[0042] Carbide slag is the industrial waste produced after the hydrolysis of calcium carbide to obtain acetylene gas, and its Ca(OH) 2 The content is 97%.

[0043] Industrial wastewater is weakly acidic wastewater discharged from pulp and paper mills.

[0044] The calcium carbide slag is sent to the digestion drum slag extractor to be mixed with Na 2 CO 3 A causticization reaction occurs. After the reaction is completed, the product is placed on the belt folding machine and washed with industrial wastewater, so that the NaOH remaining in the reaction product enters the collection tank. The water content of the washed reaction product is kept at about 75%. The reaction after washing After the product and white mud are evenly stirred, the reaction product and white mud are mixed and stirred according to the volume ratio of 1L:1.5L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com