High temperature-resistant acidic cross-linked polymer thickening agent, and preparation method and application thereof

A technology of cross-linked polymer and thickening agent, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of thermal stability, poor compatibility of salt-tolerant formation water, etc., and achieve good compatibility and low damage degree. , the effect of reducing core permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

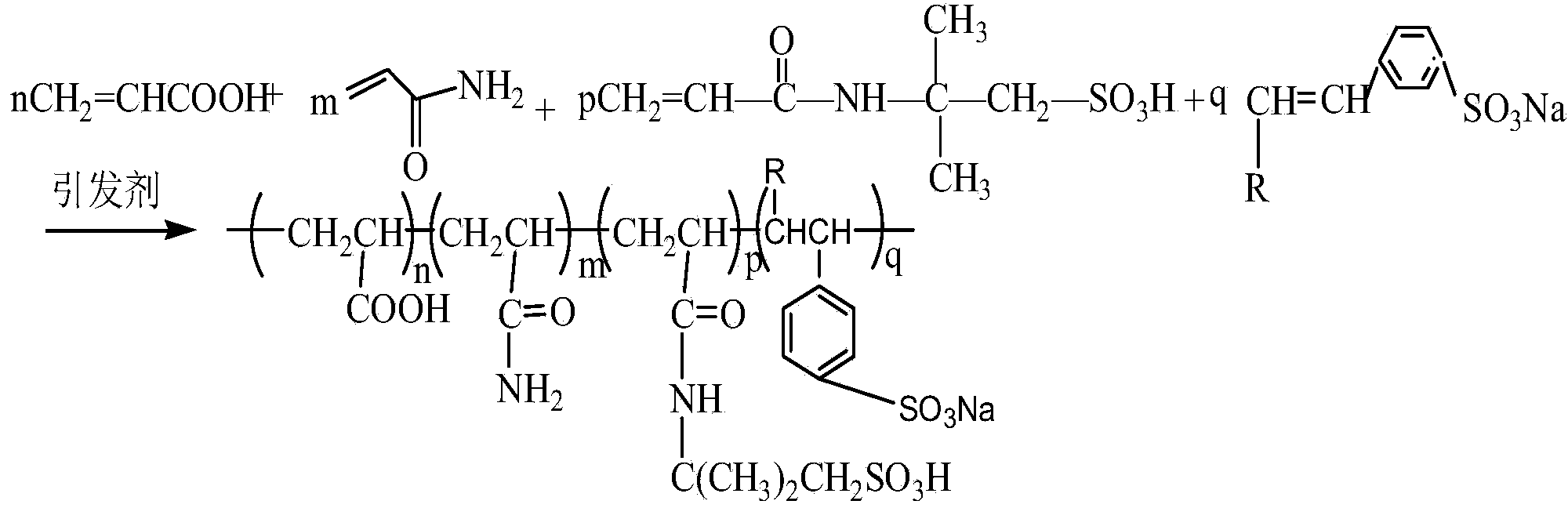

Method used

Image

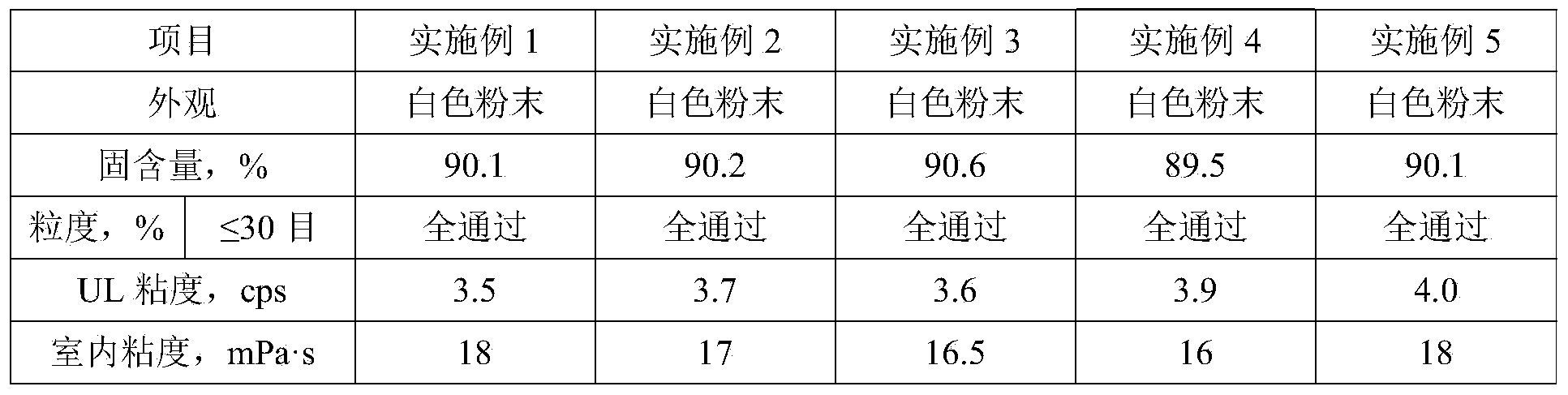

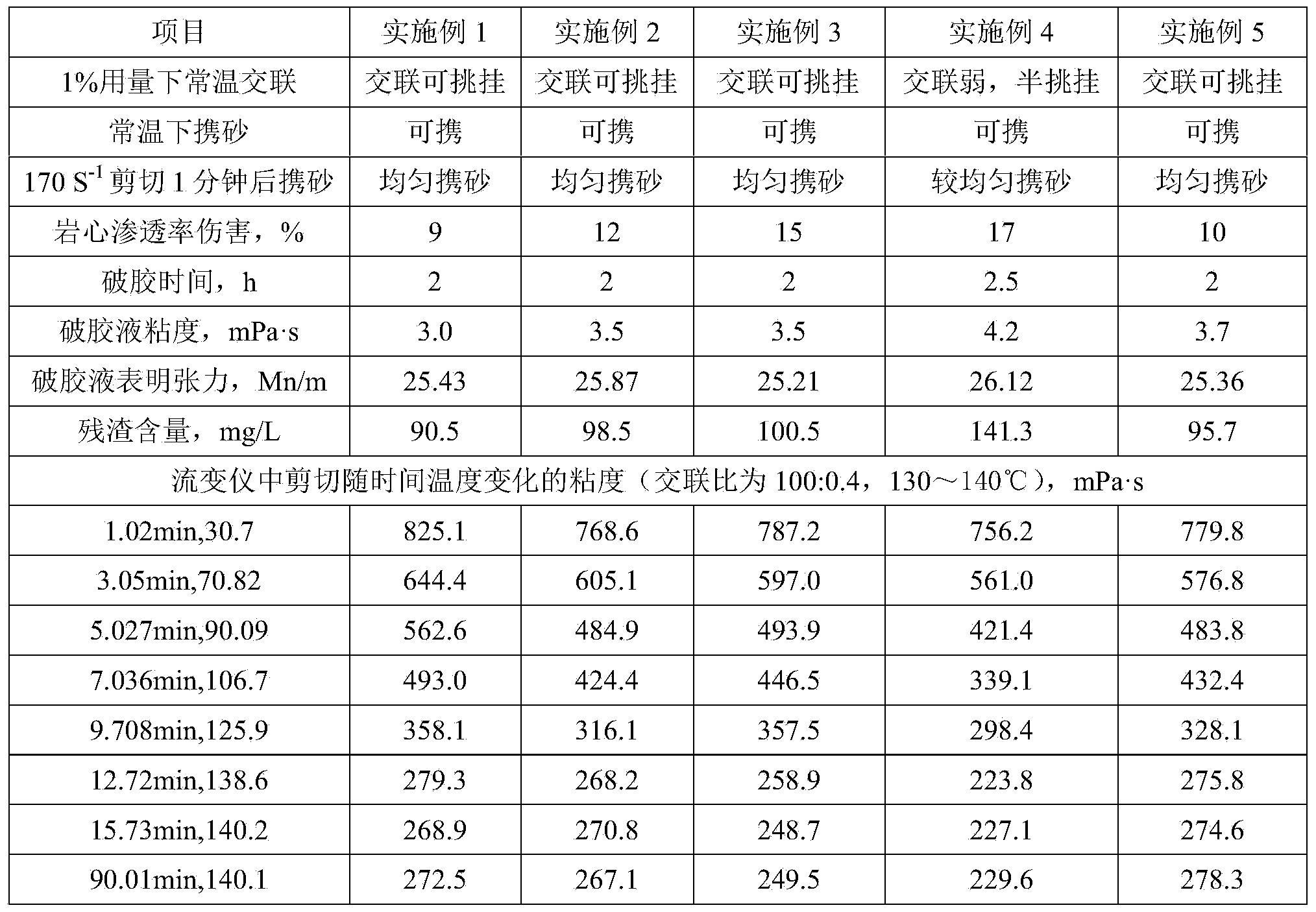

Examples

Embodiment 1

[0044] The high temperature resistant acidic cross-linked polymer thickener in this embodiment consists of four monomers of acrylic acid, acrylamide, 2-acrylamido-2-methylpropanesulfonic acid and sodium p-vinylbenzenesulfonate at a pH value of 6 aqueous solution copolymerization, wherein the mass ratio of 2-acrylamide-2-methylpropanesulfonic acid to sodium p-vinylbenzenesulfonate is 4:1, acrylic acid, acrylamide and 2-acrylamide-2 - The mass ratio of the mixture of methylpropanesulfonic acid and sodium p-vinylbenzenesulfonate is 1:8:2.

[0045] The preparation method of high temperature resistant acidic crosslinked polymer thickener in the present embodiment comprises the following steps:

[0046] (1) Solution preparation: Accurately take each monomer according to the mass ratio, add water to prepare a monomer solution with a concentration of 30%, stir and dissolve for 30 minutes, adjust the pH value of the solution to 6.5 under stirring conditions, and continue to stir and ma...

Embodiment 2

[0051] The high-temperature-resistant acidic cross-linked polymer thickener in this embodiment is composed of four monomers of acrylic acid, acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, and sodium p-propenylbenzenesulfonate at a pH value of 7 aqueous solution copolymerization, wherein the mass ratio of 2-acrylamide-2-methylpropanesulfonic acid to sodium p-propenylbenzenesulfonate is 5:1, acrylic acid, acrylamide and 2-acrylamide- The mass ratio of the mixture of 2-methylpropanesulfonic acid and sodium p-propenylbenzenesulfonate is 1.5:10:2.

[0052] The preparation method of high temperature resistant acidic crosslinked polymer thickener in the present embodiment comprises the following steps:

[0053] (1) Solution preparation: Accurately take each monomer according to the mass ratio, add water to prepare a monomer solution with a concentration of 25%, stir and dissolve for 30 minutes, adjust the pH value of the solution to 7 under stirring conditions, and continue t...

Embodiment 3

[0058] The high temperature resistant acidic cross-linked polymer thickener in this embodiment consists of four monomers of acrylic acid, acrylamide, 2-acrylamido-2-methylpropanesulfonic acid and sodium p-vinylbenzenesulfonate at a pH value of 8 aqueous solution copolymerization, wherein the mass ratio of 2-acrylamide-2-methylpropanesulfonic acid to sodium p-vinylbenzenesulfonate is 8:1, acrylic acid, acrylamide and 2-acrylamide-2 - The mass ratio of the mixture of methylpropanesulfonic acid and sodium p-vinylbenzenesulfonate is 1:15:4.

[0059] The preparation method of high temperature resistant acidic crosslinked polymer thickener in the present embodiment comprises the following steps:

[0060] (1) Solution preparation: Accurately take each monomer according to the mass ratio, add water to prepare a monomer solution with a concentration of 40%, stir and dissolve for 30 minutes, adjust the pH value of the solution to 7 under stirring conditions, and continue to stir and mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com