Method for preparation of monohydric alcohol or dihydric alcohol by low temperature selective hydrogenation of organic acid water phase

An organic acid and selective technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve problems such as high reaction temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0013] Preparation of Catalyst by Impregnation

[0014] The soluble salt solution containing 10% (mass fraction) of A is added to the carrier for impregnation according to a certain metering ratio, aged at room temperature for 12 hours, then dried in an oven at 60°C for 6 hours, and then transferred to an oven at 120°C for 6 hours; Then weigh the soluble salt solution of component B according to a certain molar ratio of B / A, add it to the above-mentioned carrier impregnated with component A, age at room temperature for 12 hours, and then dry it in an oven at 60°C for 6 hours and then transfer it to 120°C Dry in an oven for 6 hours, and bake in air at 500° C. for 3 hours to obtain a supported A-B / S catalyst. The composition of catalyst in each embodiment, the kind of starting material of component A, B is shown in Table 1.

[0015] Table 1. The composition of each catalyst

[0016] Example

[0017] Note: in each embodiment, the mass loading of A is 4%, the molar rat...

Embodiment 8-9

[0019] Catalyst activity evaluation

[0020] The catalyst evaluation of the present invention is carried out in a fixed-bed mobile phase reactor, which is a stainless steel tube with an outer diameter of 6 mm and a length of 360 mm. The experimental process is as follows: 2g of catalyst is loaded into the reaction tube, the catalyst is reduced in situ at 300°C before the reaction, and after the reduction is completed, it is lowered to the reaction temperature, and the H 2 The flow rate is 60mL / min, the flow rate of the organic acid liquid is 0.08mL / min, and the reaction pressure is 6MPa. After 6 hours of reaction, samples are taken for analysis.

Embodiment 8

[0022] Activity Evaluation of Levulinic Acid Hydrogenation to 1,4-Pentanediol

[0023] 1) Accelerator V for Rh / SiO 2 Effect on levulinic acid hydrogenation activity

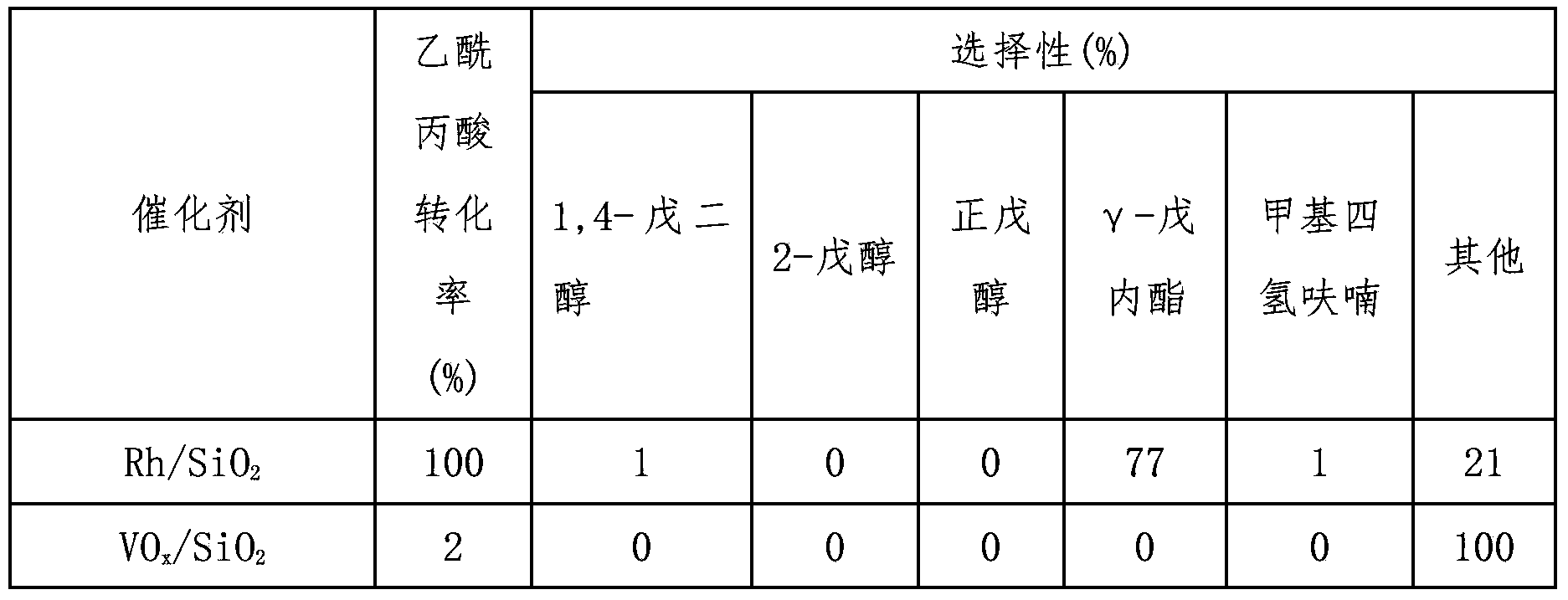

[0024] Table 2. Accelerator V for Rh / SiO 2 Influence on the hydrogenation activity of levulinic acid

[0025]

[0026]

[0027] Note: For 10% levulinic acid solution, the gas phase products are methane and pentane, etc., expressed by "other". The mass loading of Rh in a is 4%, V / Rh=0.13, and the V species in the catalyst can be either a simple substance or an oxide, so x=0-3. The reaction temperature is 80 °C.

[0028] It can be seen from Table 2 that the addition of V can significantly improve the Rh / SiO 2 The hydrogenation activity also shows that there is a synergistic effect between V and Rh so that Rh-VO x / SiO 2 It has good catalytic hydrogenation performance.

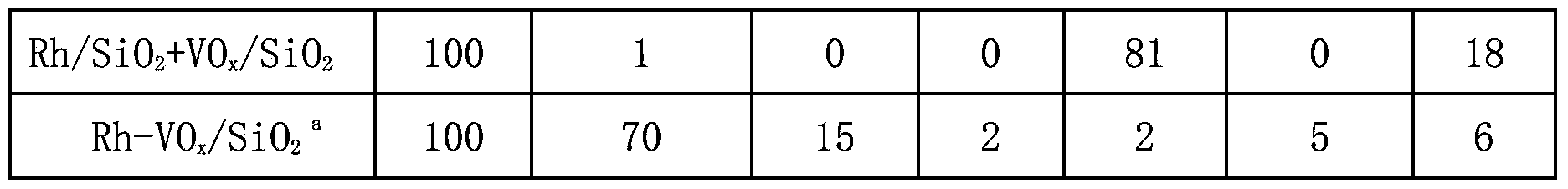

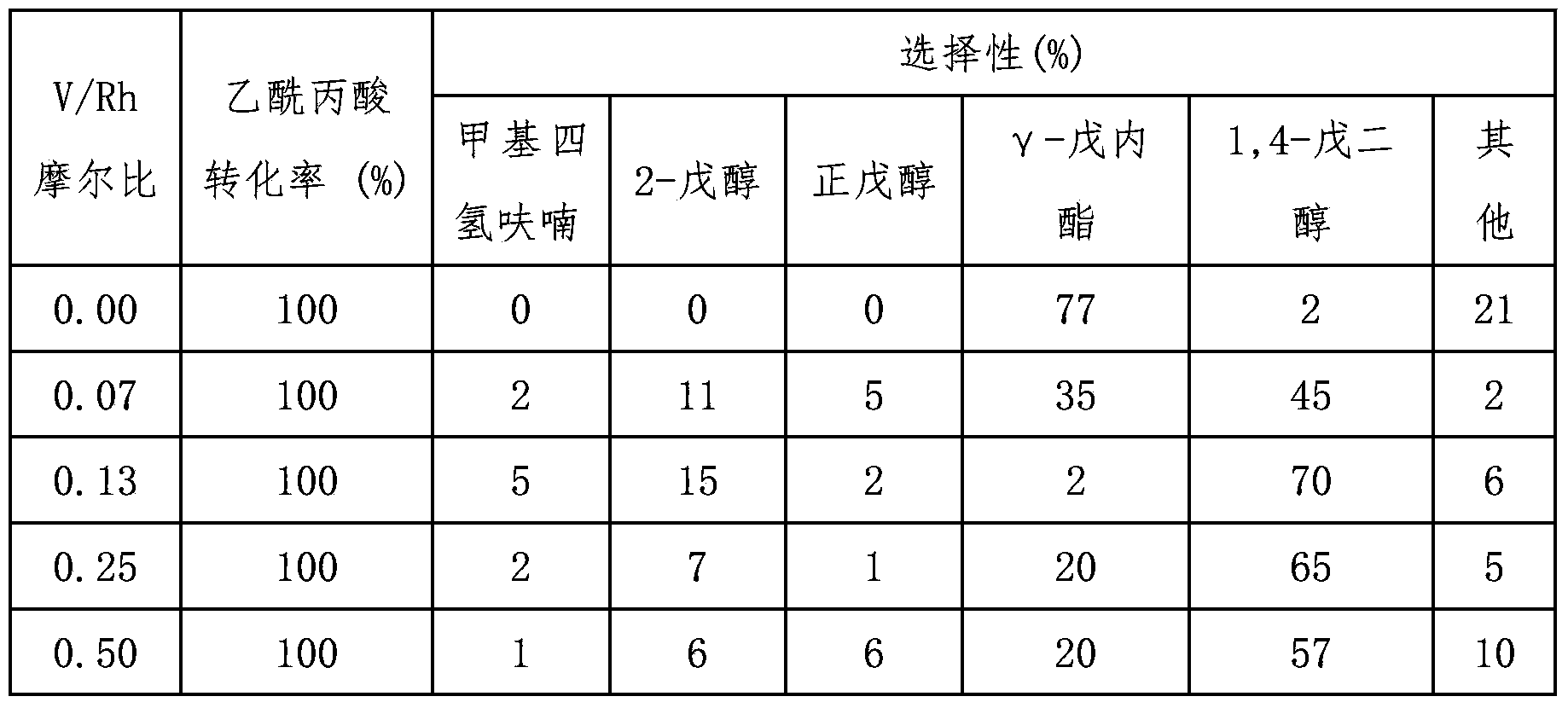

[0029] 2) The effect of catalyst V / Rh ratio on the hydrogenation activity of levulinic acid.

[0030] Table 3. Effect of V / Rh ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com