White light top emission type OLED (organic light emitting diodes) and preparation method thereof

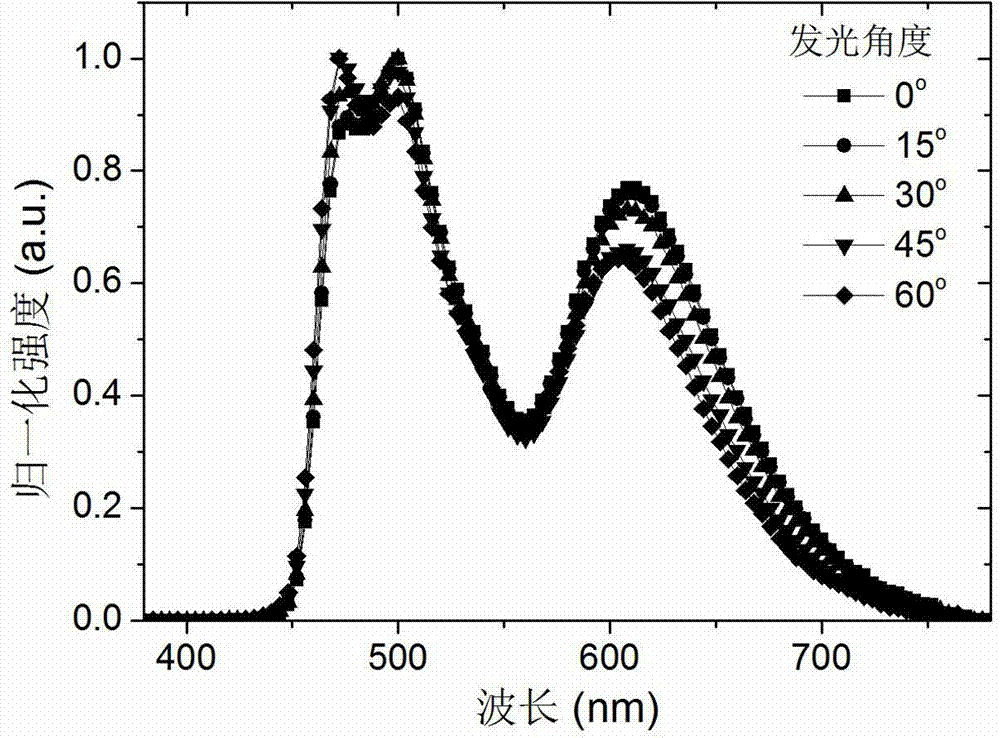

A light-emitting diode, top-emitting technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of low luminous efficiency of blue light-emitting materials, achieve simple preparation process, reduce angle dependence, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Clean the glass substrate as the substrate 1;

[0036] 2) After putting the glass substrate into the vacuum evaporation chamber, vacuumize to 5×10 -4 Above Pa; 3) Evaporate metal Ag reflective anode 2 at a deposition rate of 0.1 nm / S, with a thickness of 80 nm;

[0037] 4) Evaporation of hole injection layer 3: First, use a single-component organic material MoOx to evaporate the MoOx layer, wherein the deposition rate is 0.1 nm / S, the evaporation thickness is 2 nm, cool for 30 minutes, and then use a single-component organic material m- MTDATA evaporated the m-MTDATA layer with a deposition rate of 0.1 nm / S and a thickness of 25 nm; evaporated the hole transport layer 4 with a single-component organic material to evaporate the NPB layer with a deposition rate of 0.1 nm / S and evaporated Plating thickness is 15 nm;

[0038] 5) Evaporate the double blue light-emitting layer 5, first use the hole-type host material TCTA: the blue-light guest material FIrpic with a mass...

Embodiment 2

[0047] 1) Same as in Example 1, clean the glass substrate substrate 1, reflective anode 2, hole injection layer 3, hole transport layer 4, double blue light emitting layer 5, red light emitting layer 6, electron transport layer 7 , the evaporation of the electron injection layer 8 and the translucent cathode 9;

[0048] 2) The vapor-deposited light coupling output layer 10 is formed by vapor-depositing the single-component organic material m-MTDATA, with a thickness of 60 nm.

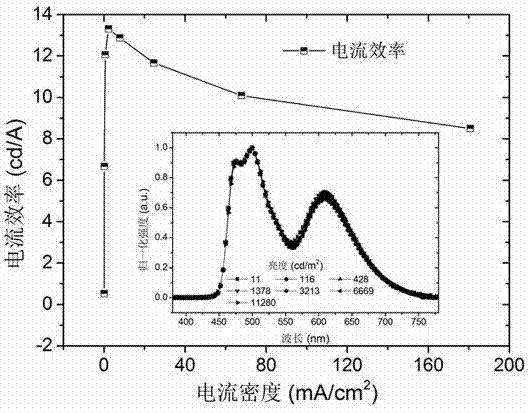

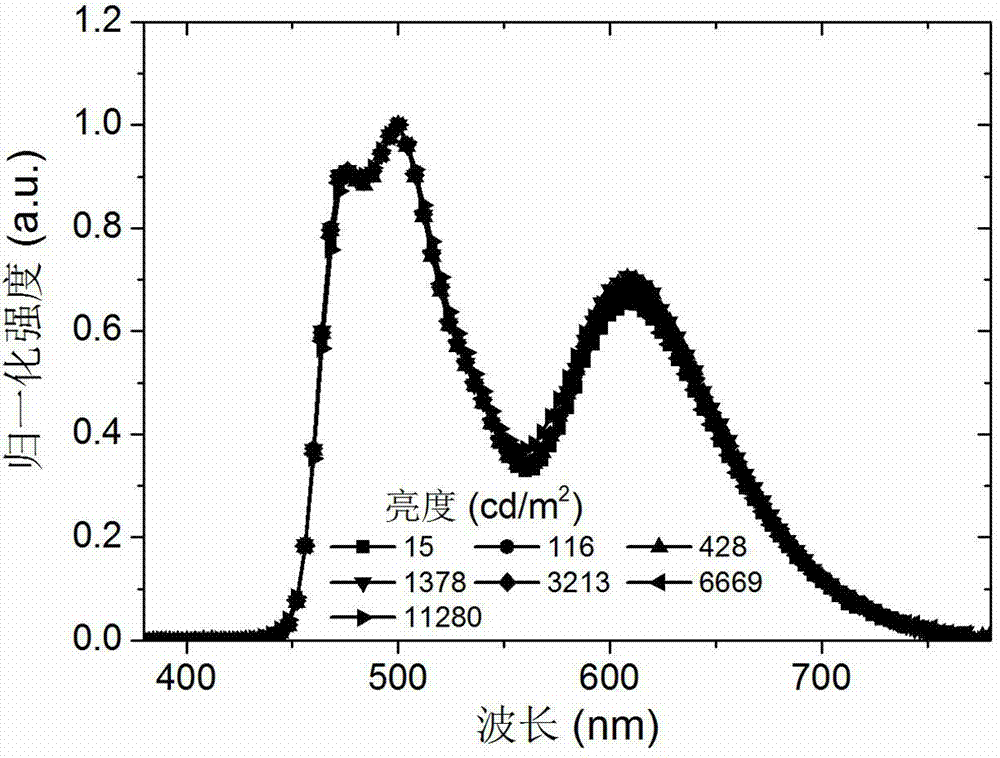

[0049] Compared with Example 1, the optical outcoupling layer of the device in Example 2 is increased to 60 nm. For m-MTDATA as the coupling output material, 60 nm is the optimal thickness, which can maximize the light output and improve the device efficiency. Through the improvement of this structure, the maximum brightness of the device in Example 2 reaches 18940 cd / m 2 , the maximum efficiency reaches 16.6 cd / A, the color coordinates are (0.31, 0.44), and the color coordinates drift during the whol...

Embodiment 3

[0052]1) Same as Example 1, cleaning of the glass substrate substrate 1, evaporation of the reflective anode 2, the hole injection layer 3, the hole transport layer 4, the double blue light emitting layer 5 and the red light emitting layer 6;

[0053] 2) The electron injection layer 8 is evaporated, and the electron transport material BPhen is used: the mass percentage is 2% Li evaporated, and the thickness is 20 nm;

[0054] 3) The same as in Example 1, conduct evaporation of the translucent cathode 9 and the optical coupling output layer 10;

[0055] 4) The current-voltage-luminance and spectral characteristics of the device are measured by Keithley2400 current source combined with PR-655 spectrometer.

[0056] Compared with Example 1, the doping concentration of Li in the electron injection layer of the device in Example 3 was reduced to 2%. Due to the reduction of electron concentration, the efficiency and chromaticity of the device are slightly changed. The device in Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com