Composite gel polymer electrolyte as well as preparation method and application thereof

A composite gel and polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve problems such as low conductivity and poor interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

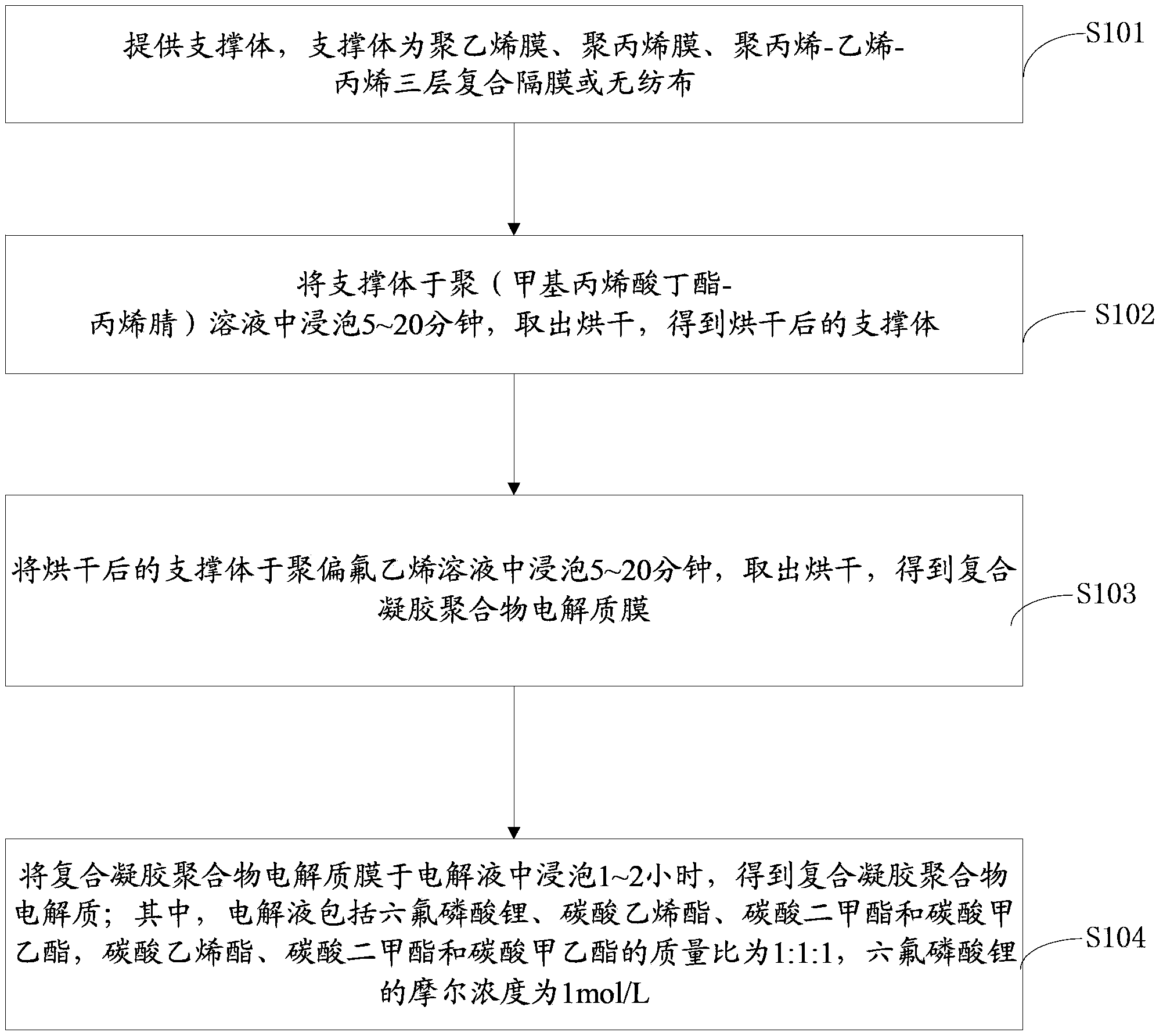

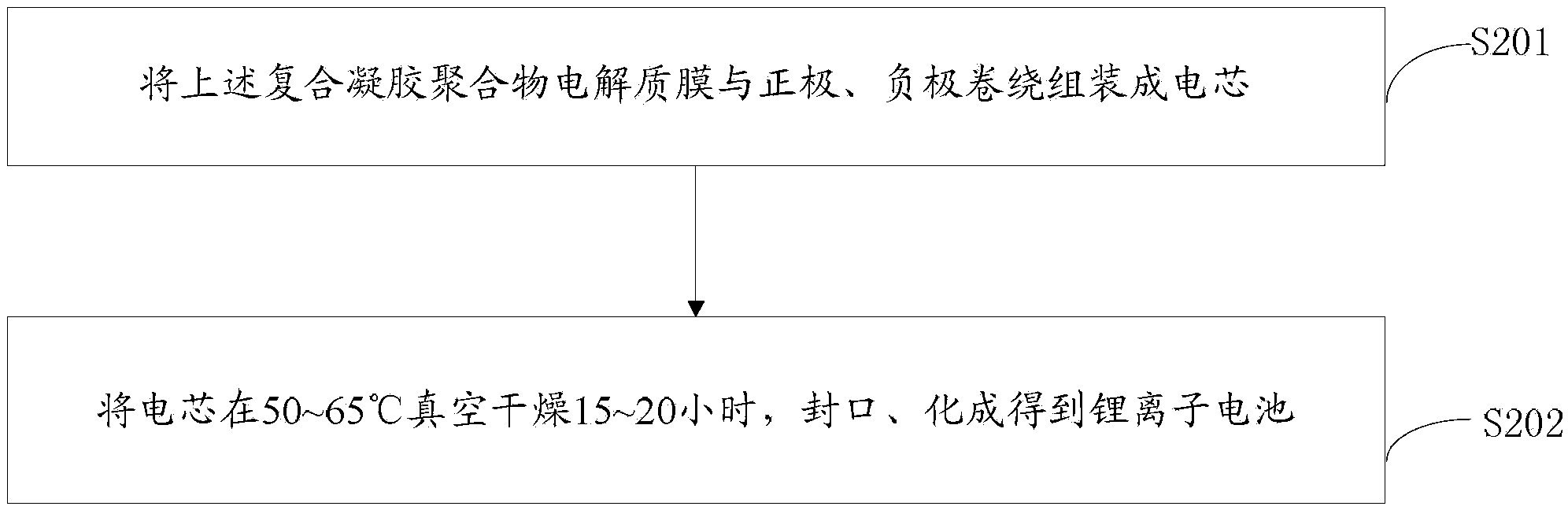

[0042] see figure 1 , the preparation method of the composite gel polymer electrolyte of an embodiment, comprises the following steps:

[0043]Step S101: providing a support body, the support body is polyethylene film, polypropylene film, polypropylene-ethylene-propylene three-layer composite membrane or non-woven fabric.

[0044] The support can enhance the mechanical strength of the composite gel polymer electrolyte and provide conditions for industrial production.

[0045] The thickness of the support is preferably 0.015 to 0.030 mm.

[0046] Step S102: Soak the support body in the poly(butyl methacrylate-acrylonitrile) solution for 5-20 minutes, take it out and dry it, and obtain the dried support body.

[0047] The preparation method of the poly(butyl methacrylate-acrylonitrile) solution is: in the atmosphere of the first protective gas, dissolve the poly(butyl methacrylate-acrylonitrile) in the first solvent, and reflux at 30-80°C Stir for 0.5-5 hours to obtain a poly...

Embodiment 1

[0074] Preparation of Composite Gel Polymer Electrolytes

[0075] (1) Dissolve P(BMA-AN) in tetrahydrofuran in a nitrogen atmosphere, reflux and stir at 45°C for 4 hours, and prepare a poly(butyl methacrylate-acrylonitrile) solution with a concentration of 3% by mass;

[0076] (2) In a nitrogen atmosphere, dissolve PVDF in acetone, reflux and stir at 45°C for 4 hours, and prepare a polyvinylidene fluoride solution with a concentration of 3% by mass;

[0077] (3) Use a polypropylene (PP) film with a thickness of 0.015mm as a support, soak the support in the poly(butyl methacrylate-acrylonitrile) solution obtained in step (1), take it out after 10 minutes, Blow drying to obtain the dried support body, then soak the dried support body in the polyvinylidene fluoride solution obtained in step (2), take it out after 10 minutes, and blow dry to obtain a composite gel polymer electrolyte membrane.

[0078] (4) After the composite gel polymer electrolyte membrane was cut to an approp...

Embodiment 2

[0080] Preparation of Composite Gel Polymer Electrolytes

[0081] (1) Dissolve P(BMA-AN) in tetrahydrofuran in a nitrogen atmosphere, reflux and stir at 30°C for 5 hours, and prepare a poly(butyl methacrylate-acrylonitrile) solution with a concentration of 6% by mass;

[0082] (2) In a nitrogen atmosphere, dissolve PVDF in tetrahydrofuran, reflux and stir at 30°C for 5 hours, and prepare a polyvinylidene fluoride solution with a concentration of 6% by mass;

[0083] (3) Use a polyethylene film (PE) with a thickness of 0.020mm as a support, soak the support in the poly(butyl methacrylate-acrylonitrile) solution obtained in step (1), take it out after 5 minutes, Blow drying to obtain the dried support body, then soak the dried support body in the polyvinylidene fluoride solution obtained in step (2), take it out after 5 minutes, and blow dry to obtain a composite gel polymer electrolyte membrane.

[0084] (4) After the composite gel polymer electrolyte membrane was cut to an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com