Preparation of Ag loaded TiO2-ZnO inverse opal photonic crystal photocatalytic material

A technology of photocatalytic materials and photonic crystals, applied in the field of photocatalysis, can solve the problems of inconvenient use, complicated post-processing, difficult recycling, etc., achieve effective degradation and improve photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

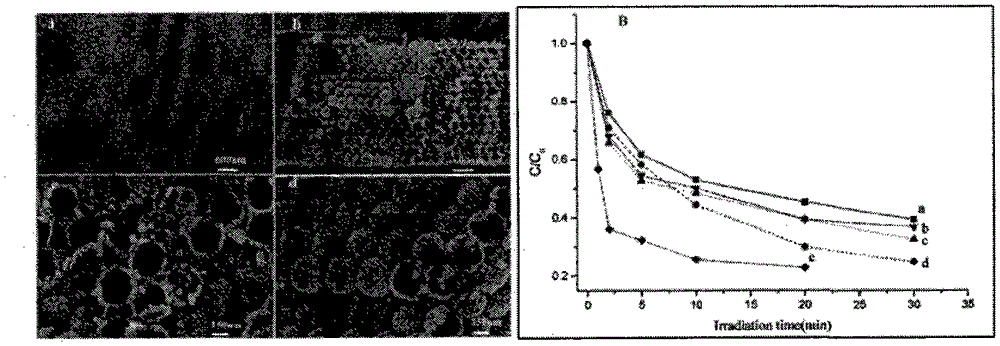

Image

Examples

Embodiment 1

[0031] 1. Preparation of opal-type polymer photonic crystal template

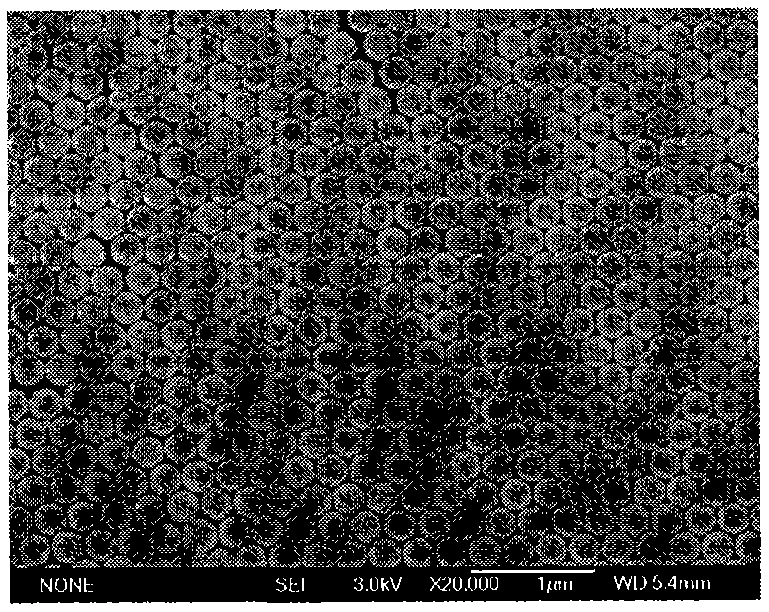

[0032] The core-shell polymer poly(styrene-acrylamide) latex microspheres with a particle size of 255 nm self-assembled on a glass substrate to form a film by vertical deposition method under constant temperature conditions. Glass substrate (1cm×3cm) in hydrogen peroxide (H 2 o 2 ) and concentrated sulfuric acid (H 2 SO 4 ) soaked in the washing solution prepared at a volume ratio of 3:7 for 2h, rinsed with a large amount of water, rinsed with distilled water, and then vertically placed in a monodisperse poly(styrene-acrylamide) water with a concentration of 0.2wt%. In a small beaker of the emulsion, the self-assembled film was formed at a constant temperature of 60°C for about 48 hours, and a red opal-type polymer photonic crystal film was obtained. The surface morphology was characterized by scanning electron microscopy, and the photonic band gap was characterized by ultraviolet-visible reflectance sp...

Embodiment 2

[0049] 1. Preparation of opal-type polymer photonic crystal template

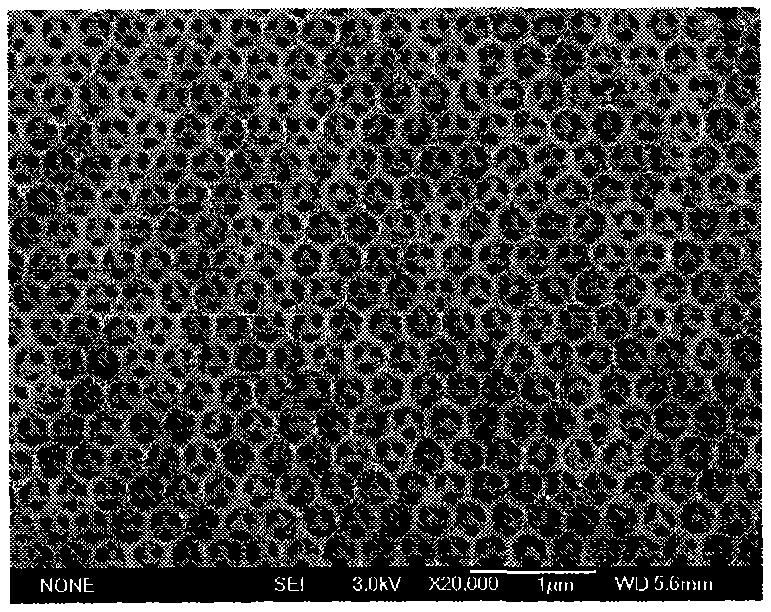

[0050] Similarly, core-shell polymer poly(styrene-acrylamide) latex microspheres with a particle size of 255 nm self-assembled on a glass substrate to form a film by vertical deposition method under constant temperature conditions. Glass substrate (1cm×3cm) in hydrogen peroxide (H 2 o 2 ) and concentrated sulfuric acid (H 2 SO 4 ) soaked in the washing solution prepared at a volume ratio of 3:7 for 1.5h, rinsed with a large amount of water, rinsed with distilled water, and then placed vertically in a monodisperse poly(styrene-acrylamide) with a concentration of 0.4wt%. In a small beaker of the water emulsion, self-assemble into a film at a constant temperature of 65° C. for about 36 hours, and a red opal-type polymer photonic crystal film is obtained. The surface morphology was characterized by scanning electron microscopy, and the photonic band gap was characterized by ultraviolet-visible reflectance s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com