A kind of soil conditioner produced by utilizing magnesium ore and shell and its production method

A technology of soil conditioner and magnesium ore, which is applied in application, fertilizer mixture, fertilization device, etc., can solve the problems of hidden dangers in food safety, decline in the quality of agricultural products, and restrictions on the development of animal husbandry, so as to achieve abundant raw materials, increase utilization rate, improve The effect of crop quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

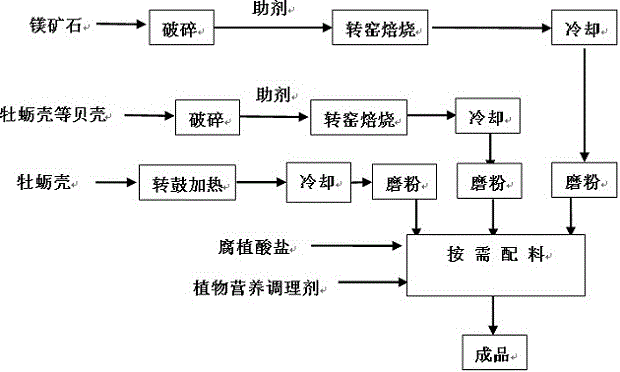

[0036] A kind of soil conditioner that utilizes magnesium ore and shell to produce and production method thereof, the technological process of present embodiment is as follows figure 1 shown. Mix magnesium ore, gypsum, and magnesium sulfate crushed to a size of about 25kg at a mass ratio of 10:1:1, and crush the mixture to a size of 50-100mm by jaw crusher or other means. Add a certain amount of coal or other fuels to the crushed mixture for roasting in a rotary kiln. The roasting temperature is controlled at 1200°C for 2 hours. After the calcination, the ingredients are cooled to about 100°C, and then ground into 0.15-0.6mm powder.

[0037]Mix marine shells such as oyster shells, gypsum, and magnesium sulfate in a mass ratio of 10:1:3, and put them into a rotary kiln for roasting. The temperature is controlled at 1100°C, and roasted for 2 hours. After the roasting, the ingredients are cooled to about 100 ℃, and then pulverized into 0.15 ~ 0.6mm powder.

[0038] The oyster ...

Embodiment 2

[0043] A kind of soil conditioner that utilizes magnesium ore and shell to produce and production method thereof, the technological process of present embodiment is as follows figure 1 shown. Mix magnesium ore, gypsum, magnesium sulfate, and sodium sulfate crushed to a size of about 25kg in parts by mass of 10:1:1:1, and crush the mixture to 50-100mm by jaw crusher or other means. Add a certain amount of coal or other fuels to the crushed mixture in the rotary kiln for roasting, the roasting temperature is controlled at 1300°C, and roasted for 1 hour. After the calcination, the ingredients are cooled to about 100°C, and then ground into 0.15-0.6mm powder.

[0044] Mix marine shells such as oyster shells, gypsum, magnesium sulfate, and sodium sulfate in a mass ratio of 10:2:3:1, and put them into a rotary kiln for roasting. The temperature is controlled at 1200°C for 1 hour. After the roasting, the ingredients Cool to about 100°C, and then grind into 0.15-0.6mm powder.

[00...

Embodiment 3

[0050] A kind of soil conditioner that utilizes magnesium ore and shell to produce and production method thereof, the technological process of present embodiment is as follows figure 1 shown. Mix magnesium ore and gypsum that have been crushed to a size of about 25kg at a mass ratio of 10:1, and crush the mixture to 50-100mm by jaw crusher or other methods. Add a certain amount of coal or other fuels to the crushed mixture in the rotary kiln for roasting, the roasting temperature is controlled at 1300°C, and roasted for 1 hour. After the calcination, the ingredients are cooled to about 100°C, and then ground into 0.15-0.6mm powder.

[0051] Mix marine shells such as oyster shells, gypsum, magnesium sulfate, and sodium sulfate in a mass ratio of 10:1:1:1, and put them into a rotary kiln for roasting. The temperature is controlled at 1200°C for 1.5 hours. After the roasting, the ingredients Cool to about 100°C, and then grind into 0.15-0.6mm powder.

[0052] The oyster shells...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com