Micro-nano modified super bright polyester fibers and preparation method thereof

A bright polyester, micro-nano technology, applied in the field of polyester fibers, can solve the problems of no substantial progress, complex process, low specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

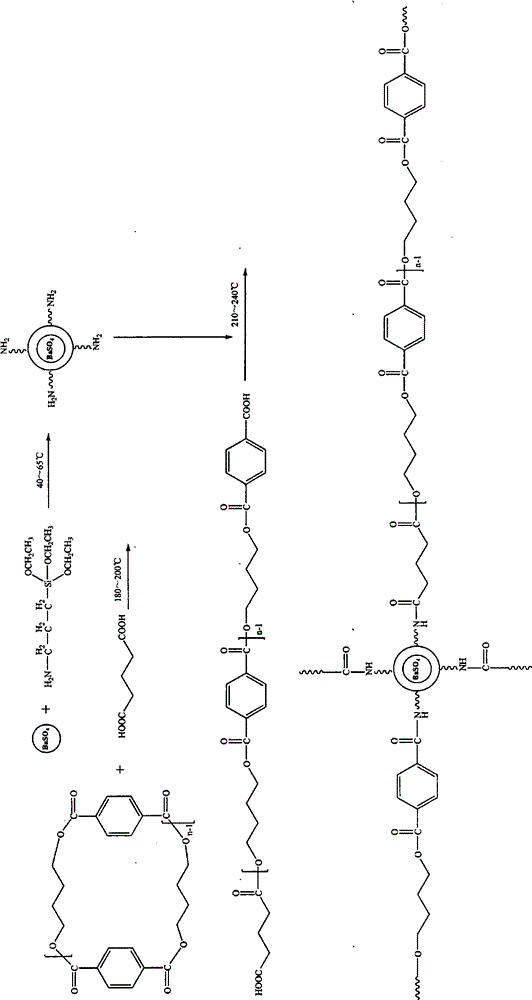

[0044] A preparation method of micro-nano modified bright polyester fiber, the specific process is:

[0045] (1) Amination treatment of nano barium sulfate

[0046] Dissolve nano barium sulfate in ethanol solvent, the concentration of nano barium sulfate in ethanol is 10kg / m 3 , the pH of the ethanol solvent is controlled to be 8, and then aminopropyltriethoxysilane is added for reaction; the aminopropyltriethoxysilane is 1% of the mass of nano barium sulfate, the reaction temperature is 60°C, and the reaction time is 60-80min Carry out centrifugation after the completion of the reaction, and vacuum dry the solid to prepare aminated nano-barium sulfate;

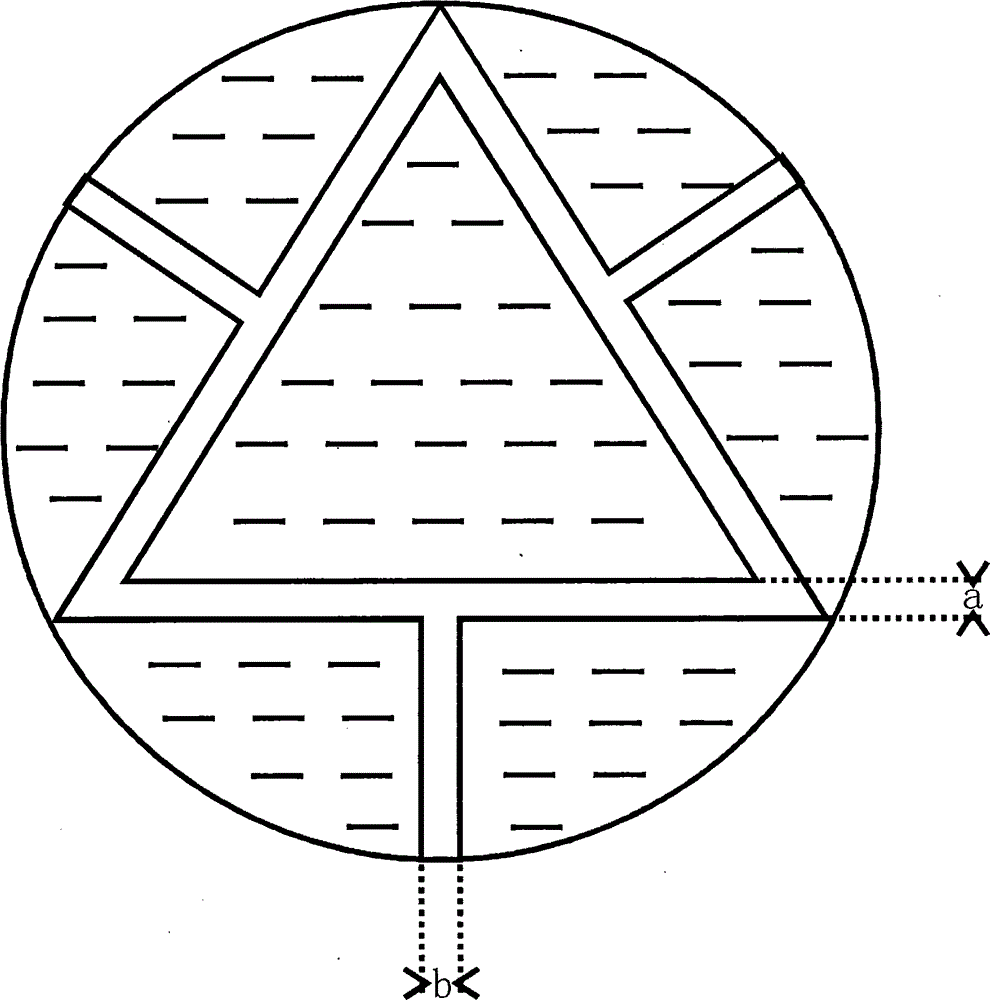

[0047] (2) spinning

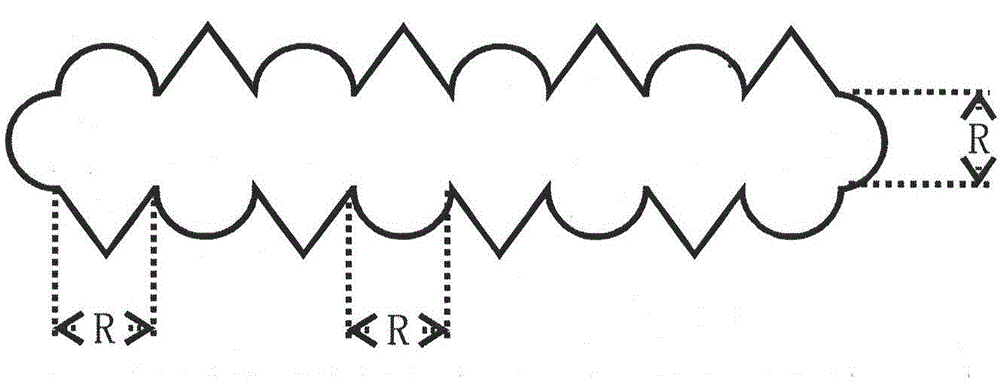

[0048] Under the protection of nitrogen, according to the molar ratio of terephthalic acid and ethylene glycol in the raw material is 1: 1.2, the added amount of aminated nano-barium sulfate is 5% of the mass fraction of terephthalic acid for batching; the aminated nano-barium sulfate Barium sulfate is ...

Embodiment 2

[0055] A preparation method of micro-nano modified bright polyester fiber, the specific process is:

[0056] (1) Amination treatment of nano barium sulfate

[0057] Dissolve nano barium sulfate in ethanol solvent, the concentration of nano barium sulfate in ethanol is 10kg / m 3 , the pH of the ethanol solvent is controlled to be 8, and then aminopropyltriethoxysilane is added for reaction; the aminopropyltriethoxysilane is 1% of the mass of nano barium sulfate, the reaction temperature is 60°C, and the reaction time is 60-80min Carry out centrifugation after the completion of the reaction, and vacuum dry the solid to prepare aminated nano-barium sulfate;

[0059] (1) Heat the CBT powder to 180-200°C, then add bio-based glutaric acid, and at the same time add the catalyst dihydroxyalkyl tin chloride to carry out carboxylation of CBT, the reaction time is 20-30min, and carboxyl Acid-terminated CBT initial polymer;

[0060] Described catalyst is dihy...

Embodiment 3

[0079] A preparation method of micro-nano modified bright polyester fiber, the specific process is:

[0080] (1) Amination treatment of nano barium sulfate

[0081] Dissolve nano barium sulfate in ethanol solvent, the concentration of nano barium sulfate in ethanol is 40kg / m 3 , the pH of the ethanol solvent is controlled to be 9, and then aminopropyltriethoxysilane is added to react; aminopropyltriethoxysilane is 0.5% of the quality of nano-barium sulfate, the reaction temperature is 60 ° C, and the reaction time is 80min; Carry out centrifugation after completion, vacuum-dry the solid to prepare aminated nano-barium sulfate;

[0082] (2) spinning

[0083] Under the protection of nitrogen, according to the molar ratio of terephthalic acid and ethylene glycol in the raw material is 1: 1.6, the added amount of aminated nano barium sulfate is 5% of the mass fraction of terephthalic acid for batching; the aminated nano Barium sulfate is added to the ethylene glycol raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com