A continuous production method of high-activity fly maggot protein powder

A protein powder, high activity technology, applied in the direction of protein composition of microorganisms, protein components of waste, protein components of plant materials, etc., can solve the problem of not using deodorization and deodorization technology, less active ingredients, long reaction time, etc. problem, achieve the effect of retaining the activity of fly maggot protein, increasing the specific surface area and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

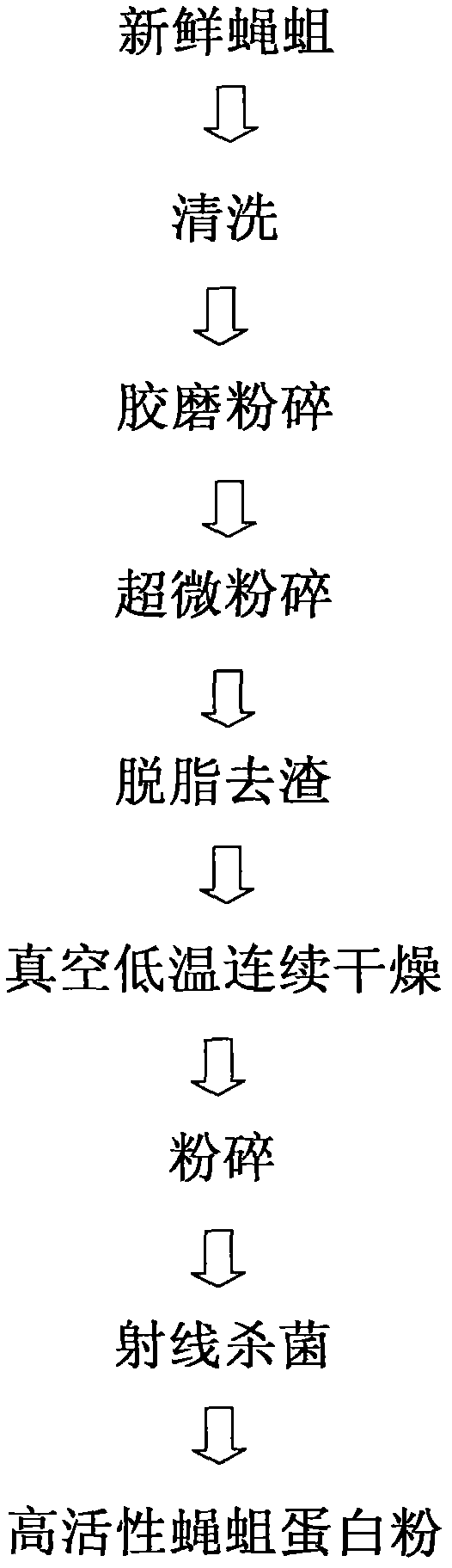

[0029] Using fresh fly maggots as raw materials, the highly active fly maggot protein powder is prepared by washing, rubber mill crushing, superfine crushing, degreasing and slag removal, vacuum low-temperature continuous drying, crushing, and radiation sterilization. The specific implementation is as follows:

[0030] (1) Cleaning: fresh fly maggots are cleaned;

[0031] (2) Rubber mill crushing: add 2 to 3 parts of water to mix and carry out rubber mill crushing to obtain 3 to 4 parts of fly maggot slurry, the particle size of fly maggot crushing is below 50μ, and the temperature condition is 20-40°C;

[0032] (3) Superfine crushing: carry out superfine crushing to the fly maggot slurry, the particle size of the fly maggot crushing is 2-10μ, and the temperature condition is 20-40°C;

[0033] (4) Degreasing and slag removal: remove the fat in the fly maggot slurry, remove the liquid slag composed of impurities and larger particle size maggot skin to obtain the maggot protein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com