Composite functional infrared reflective engineering machinery powder coating and its production process

An infrared reflective pigment and infrared reflective technology, applied in the production of powder coatings, reflective/signal coatings, bulk chemicals, etc., can solve problems such as not very easy, numerous devices, cumbersome production processes, etc. Baking temperature, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of polyester / acrylic resin composite 1: It is prepared by mixing polyester resin and acrylic resin in a weight ratio of 7:3, and reacting in a high-temperature reactor at 150° C. for 1 hour.

[0046] Preparation of epoxy-modified acrylic resin: using methyl methacrylate, acrylic acid, octyl acrylate, styrene, hydroxypropyl acrylate, trimethylolpropane triacrylate as monomers, benzoyl peroxide as initiator, E-44 epoxy resin is used as modifier and polymerized.

[0047] Preparation of nanocomposite cross-linking agent: 4,5-imidazole dicarboxylic acid and benzimidazole-5,6-dicarboxylic acid as sensitized organic ligands, grafted onto mesoporous SiO through covalent bonds 2 On the nanoparticles, a nanocomposite cross-linking agent is prepared.

[0048] The infrared reflective pigment is rutile nano-titanium dioxide, and the polyester resin is 9855 polyester resin supplied by Baotian New Materials.

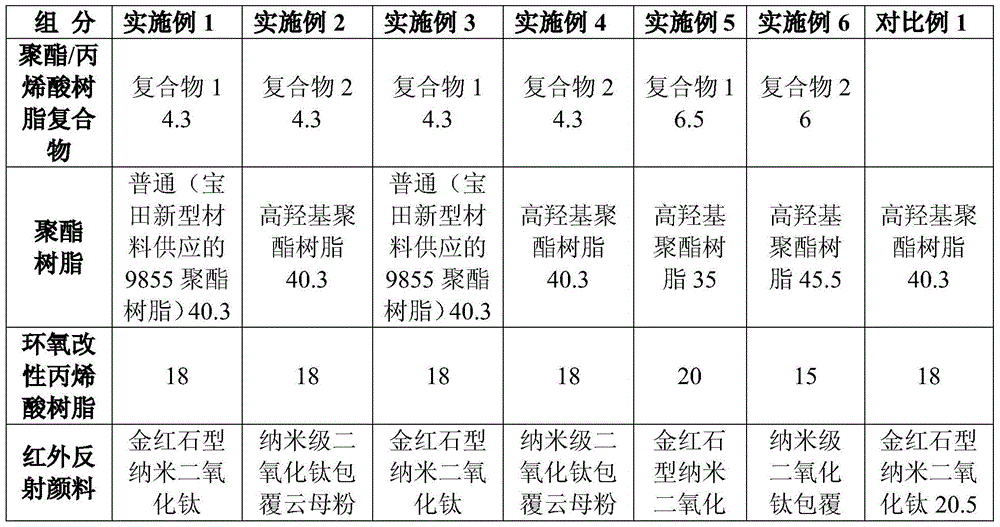

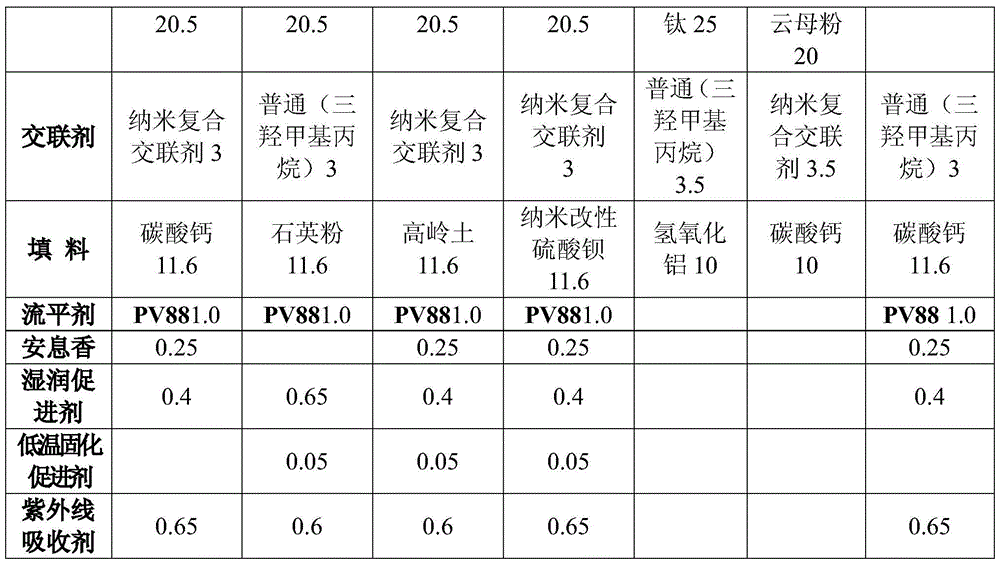

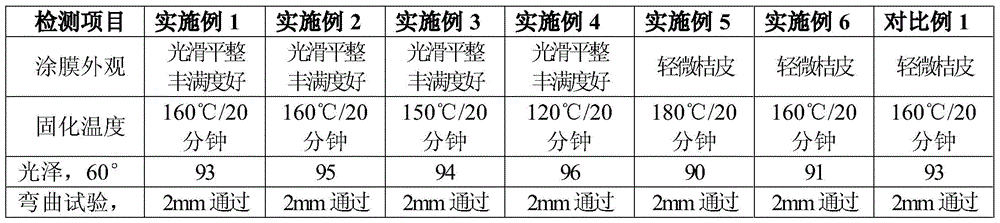

[0049] The raw material components of the powder coating are ...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, and its difference is:

[0054] To prepare polyester / acrylic composite 2, react for 1.5 hours.

[0055] The method of CN103467714A is adopted to prepare high hydroxyl polyester resin.

[0056] The method of CN102795663A is adopted to prepare nanoscale titanium dioxide-coated mica powder.

[0057] The crosslinking agent is trimethylolpropane.

[0058] In addition, the additives are different, see Table 1 for details.

Embodiment 3

[0060]This embodiment is basically the same as Embodiment 1, the difference is that the additives are different, the temperature of the supercritical fluid tank is set to 120 ° C, after heating to the set temperature, the temperature is kept constant for 5 minutes, and the rotation speed of the shearing element is 150 rpm / min, the shear mixing time is 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com