Preparation method of amphoteric polycarboxylate clay inhibitor

A technology of amphoteric polycarboxylate and clay inhibitors, which is applied in the field of preparation of amphoteric polycarboxylate clay inhibitors, can solve problems affecting the later strength of concrete, reduce strength and durability, increase concrete shrinkage, etc., and achieve shielding It has good dispersion effect, improves the ability to resist clay, and is beneficial to industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

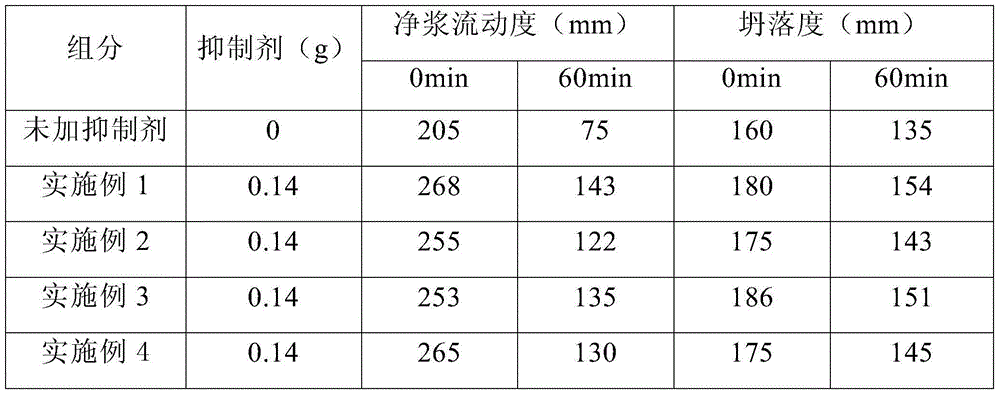

Examples

Embodiment 1

[0018] In a reactor with a reflux and stirring device, dissolve 2.5 g of unsaturated sulfonate monomer and 1.5 g of methacryloyloxyethyl dimethylamine in 60 g of deionized water, stir to dissolve, and heat up to 60 At ℃, start to add 2.0g ammonium persulfate dissolved in 12g deionized water and 32.5g unsaturated carboxylic acid monomer by dropping at the same time, control the dropwise addition in 1.5 hours, keep the temperature for 4.0 hours, and then cool down to 40 After ℃, use 0.5g of dimethyl sulfate for quaternization for 1 hour, add sodium hydroxide to neutralize to pH = 5-6, and obtain a light yellow viscous transparent liquid, which is an amphoteric polycarboxylic acid Salt clay inhibitor.

Embodiment 2

[0020] In a three-port reactor with reflux and stirring devices, dissolve 3g of unsaturated sulfonate monomer and 1.5g of methacryloyloxyethyl dimethylamine in 65g of deionized water, stir to dissolve, and heat up to 85°C. At the same time, dissolve 2.0g potassium persulfate and 37.5g acrylic acid monomer with 12g deionized water by dropwise addition, control the dropwise addition in 2.0 hours, and keep it warm for 3.0 hours, then cool down to 45°C, use 0.5g sulfuric acid Dimethyl ester was subjected to quaternization reaction for 1 hour, and then neutralized with sodium hydroxide to pH=5-6 to obtain a light yellow viscous transparent liquid, which was an amphoteric polycarboxylate clay inhibitor.

Embodiment 3

[0022] In a three-port reactor with reflux and stirring devices, dissolve 5g of unsaturated sulfonate monomer and 2.5g of methacryloyloxyethyl dimethylamine in 70g of deionized water, stir to dissolve, and heat up to 80°C , start to add 2.0g of sodium persulfate initiator and 35g of methacrylic acid monomer dissolved in 12g of deionized water at the same time by dropwise addition, control the dropwise addition in 2.0 hours, and keep the reaction for 3.5 hours, and then cool down to 40°C, Use 1.0g of diethyl sulfate for quaternization for 1.5 hours, and then neutralize with sodium hydroxide to pH=5-6 to obtain a light yellow viscous transparent liquid, which is an amphoteric polycarboxylate clay inhibitor agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com