Preparation method for silver-zinc oxide nano-composite structure

A zinc oxide nanotechnology, composite structure technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve mild reaction conditions, easy large-scale industrial production, and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 nano silver sol

[0028] Add 0.5mL concentrated ammonia water (26-28%) into 1L deionized water, stir continuously at a speed of 150-250rpm, adjust the pH value of the solution to 11.5 with 0.5M NaOH aqueous solution, add 0.1mM maltose, 0.01mM silver nitrate , and stirred in the dark for 20 minutes to obtain nano-silver sol.

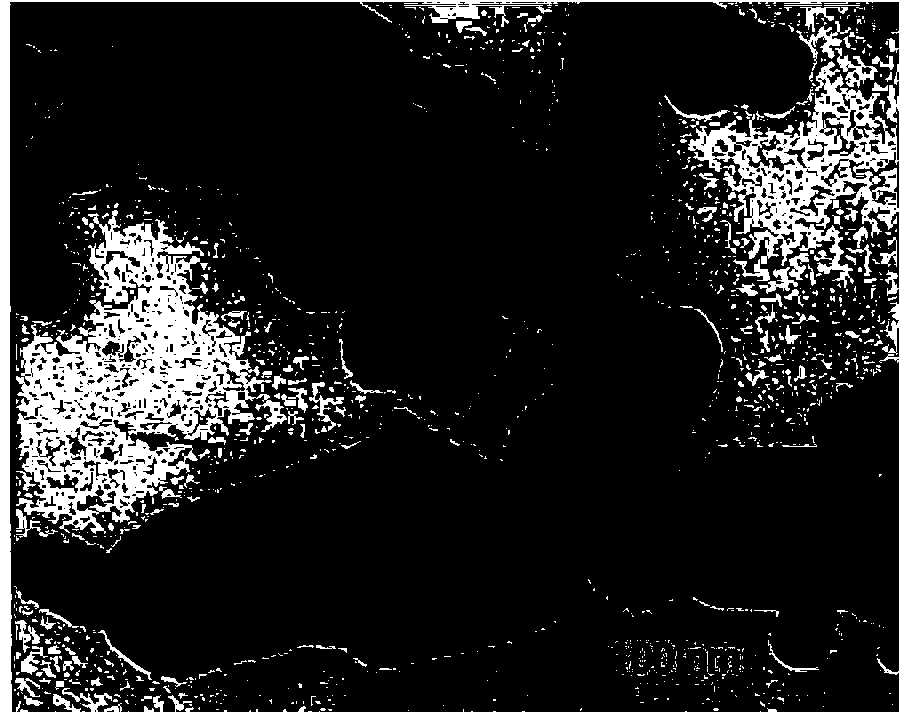

[0029] figure 1 Shown is the transmission electron microscope (TEM) photo of the nano silver particles obtained in this example. It can be seen from the TEM photo that the obtained nano-silver has a uniform appearance, a spherical shape, a uniform size, and a particle diameter of about 20 nm. The zeta potential of the sample was -35.7mV.

Embodiment 2

[0030] The preparation of embodiment 2 nano-silver sol

[0031] Add 0.5mL concentrated ammonia water (26-28%) into 1L deionized water, stir continuously at a speed of 150-250rpm, adjust the pH value of the solution to 11.3 with 0.5M NaOH aqueous solution, add 0.1mM glucose, 0.01mM silver nitrate , and stirred in the dark for 20 minutes to obtain nano-silver sol.

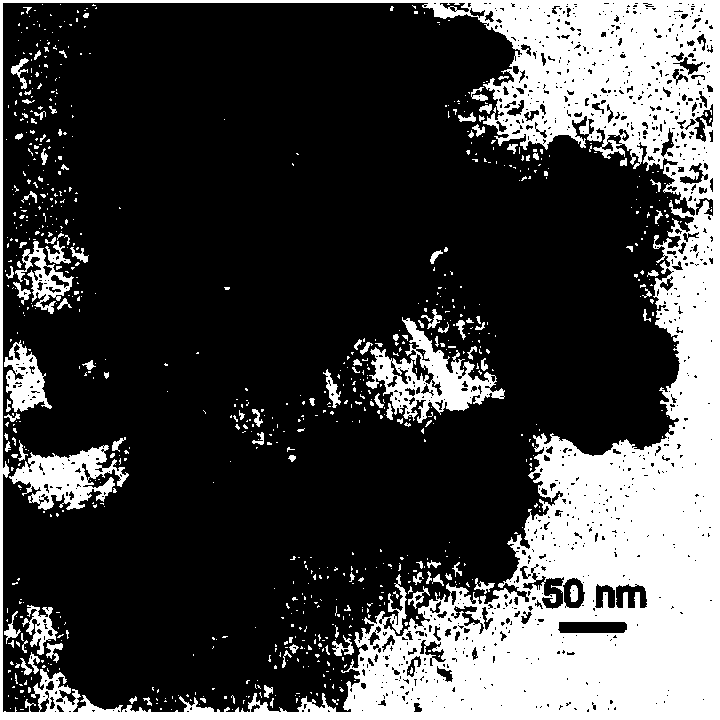

[0032] figure 2 Shown is the transmission electron microscope (TEM) photo of the nano silver particles obtained in this example. It can be seen from the TEM photographs that the obtained nano-silver has a regular shape, a spherical shape, a uniform size, and a particle size of about 60 nm. The zeta potential of the sample was -34.5mV.

Embodiment 3

[0034] Weigh 1.25g of commercial zinc oxide powder (AR, Sinopharm Group, Shanghai), add it to 500ml of the nano-silver sol prepared in Example 1, ultrasonically disperse for 5 minutes, stir mechanically for 1 hour, centrifuge the product, and wash with absolute ethanol 3 times, vacuum-dried at 60°C for 12 hours to obtain Ag-ZnO nanocomposites, and the loading of silver in the sample was analyzed by plasma emission spectroscopy to be 4.34% (w / w),

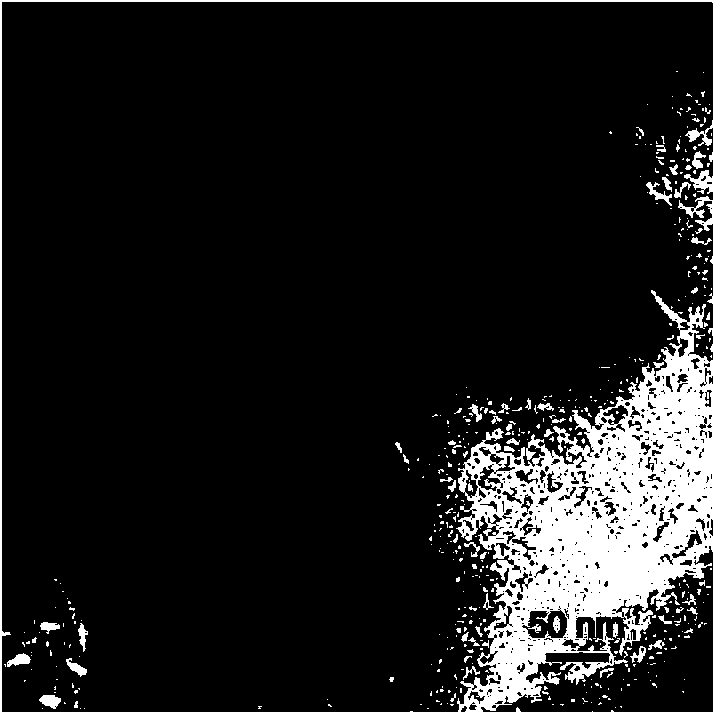

[0035] image 3 Shown is a scanning electron microscope (SEM) photo of the commercial zinc oxide powder used in this example. It can be seen from the figure that the powder has an irregular shape and a size between 50 and 200 nm. The zeta potential of the sample was 20.8 mV.

[0036] Figure 4 Shown is the TEM image of the Ag-ZnO nanocomposite obtained in the example. It can be seen from the figure that the silver nanoparticles are uniformly loaded on the surface of the zinc oxide particles.

[0037] Figure 5 Shown is the X-ray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com