Total mixed ration for dairy cows in later perinatal period and preparation method thereof

A technology for postpartum and dairy cows, applied in applications, animal feed, animal feed, etc., can solve problems such as failure of active ingredients, waste of feed resources, and influence on mixing uniformity, so as to reduce the occurrence of metabolic diseases, prolong the peak time, and formulate Reasonable effect than design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

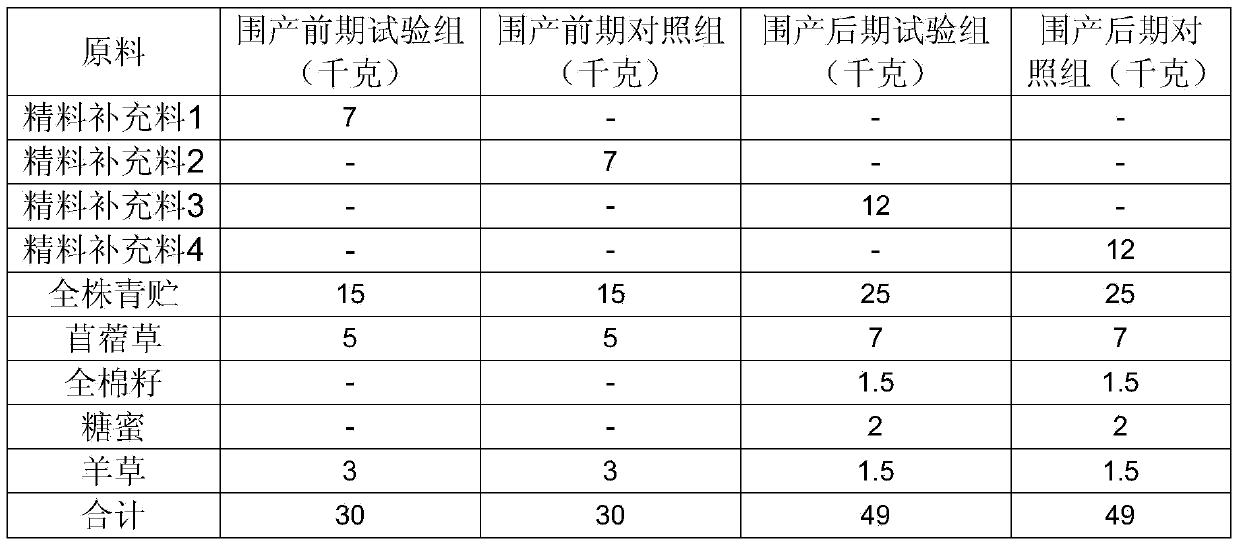

[0050] A complete mixed ration for dairy cows in the postpartum period. Each 49kg total mixed ration contains 12kg of concentrate supplement, 25kg of whole plant silage, 7kg of alfalfa, 1.5kg of whole cottonseed, 2kg of molasses and 3kg of Leymus chinensis.

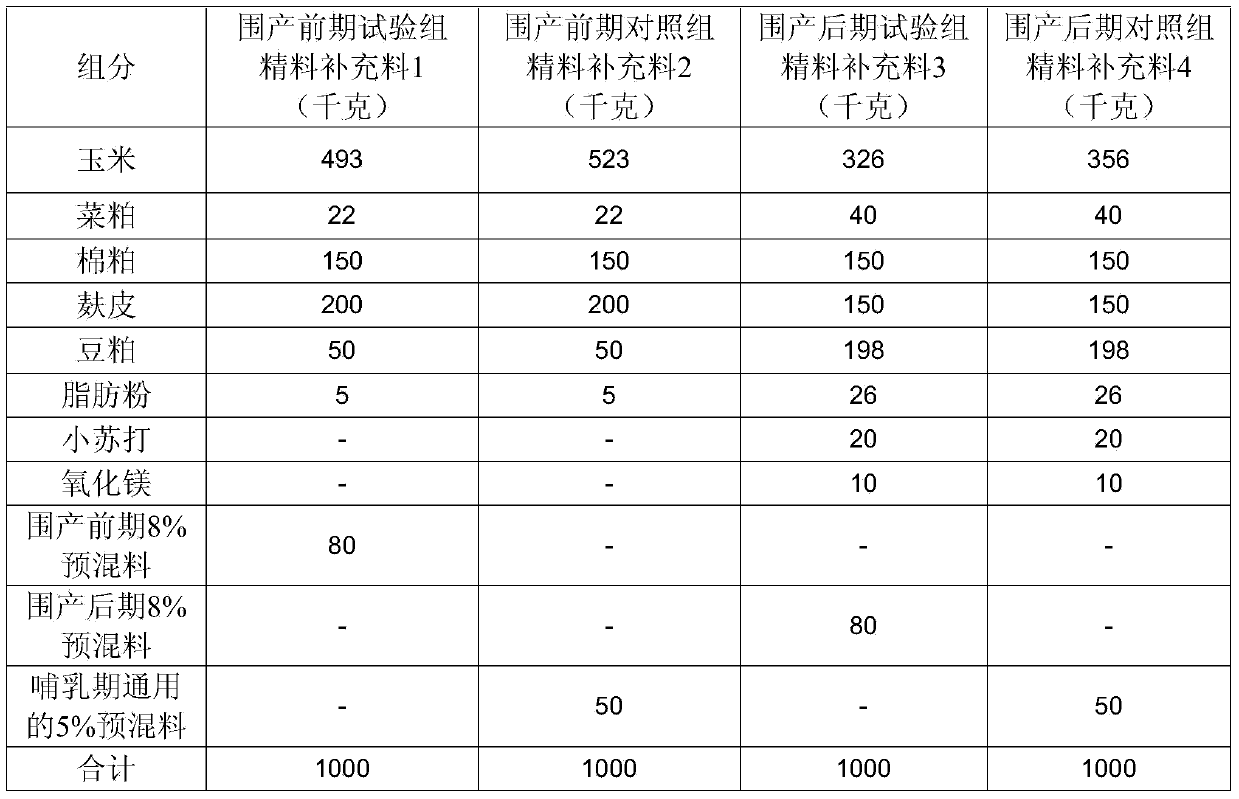

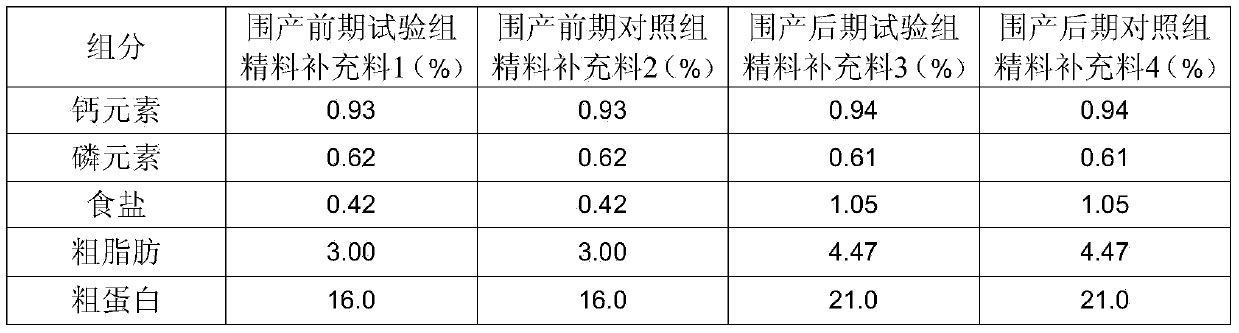

[0051] Each ton of post-perinatal concentrate supplement includes the following components: 80kg of post-perinatal premix, 326kg of corn, 40kg of rapeseed meal, 150kg of cottonseed meal, 150kg of bran, 198kg of soybean meal, 26kg fat powder, 20kg of baking soda and 10kg of magnesium oxide. Among them: the components and content of each ton of perinatal premix are: stone powder: 75 kg, calcium hydrogen phosphate: 100 kg, salt: 95 kg, yeast culture: 55 kg, 25% copper sulfate: 1.4 Kg, 10% organic copper: 1.4 kg, 24% cobalt sulfate: 0.2 kg, 75% zinc oxide: 1 kg, 12% organic zinc: 4.3 kg, potassium iodide diluted to 7.5%: 0.9 kg, 45% Potassium chloride: 3.2 kg, 30% ferrous sulfate: 2.1 kg, 30% manganese sulfate: 3.4 kg, 8% o...

Embodiment 2

[0053] A complete mixed ration for dairy cows in the postpartum period. Each 49kg total mixed ration contains 12kg of concentrate supplement, 25kg of whole plant silage, 7kg of alfalfa, 1.5kg of whole cottonseed, 2kg of molasses and 3kg of Leymus chinensis.

[0054] Each ton of post-perinatal concentrate supplement includes the following components: 80kg of post-perinatal premix, 326kg of corn, 40kg of rapeseed meal, 150kg of cottonseed meal, 150kg of bran, 198kg of soybean meal, 26kg fat powder, 20kg of baking soda and 10kg of magnesium oxide. Among them: the components and content of each ton of perinatal premix are: stone powder: 100 kg, calcium hydrogen phosphate: 90 kg, salt: 105 kg, yeast culture: 45 kg, 25% copper sulfate: 1.4 Kg, 10% organic copper: 1.4 kg, 24% cobalt sulfate: 0.2 kg, 75% zinc oxide: 1 kg, 12% organic zinc: 4.3 kg, potassium iodide diluted to 7.5%: 0.9 kg, 45% Potassium chloride: 3.2 kg, 30% ferrous sulfate: 2.1 kg, 30% manganese sulfate: 3.4 kg, 8% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com