A preparation method for controlling the morphology of graphene oxide nanostructures

A nanostructure and graphene technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of low cost, controllable performance and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

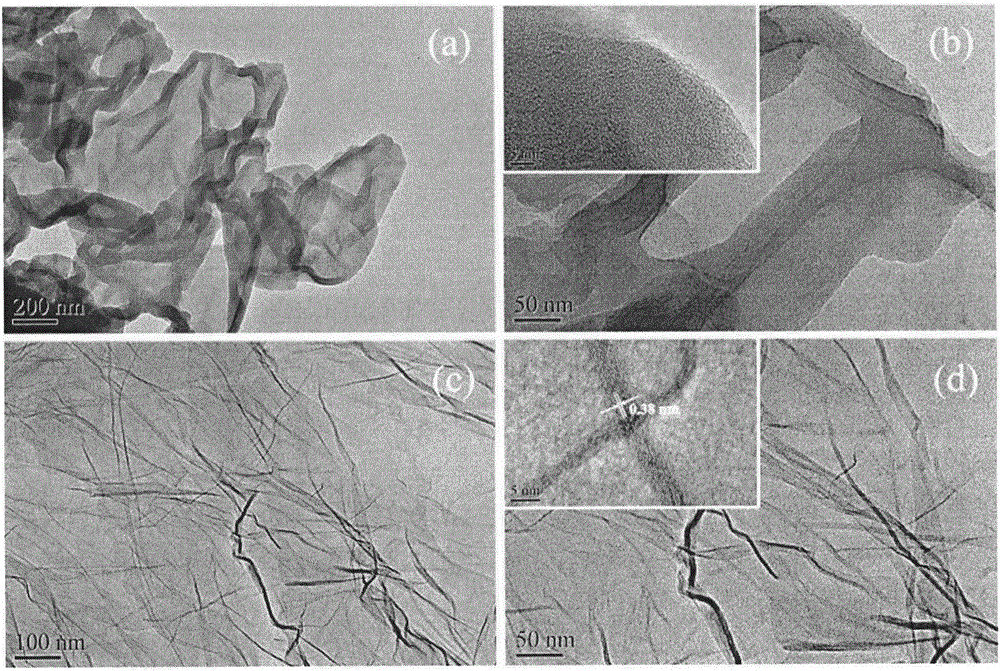

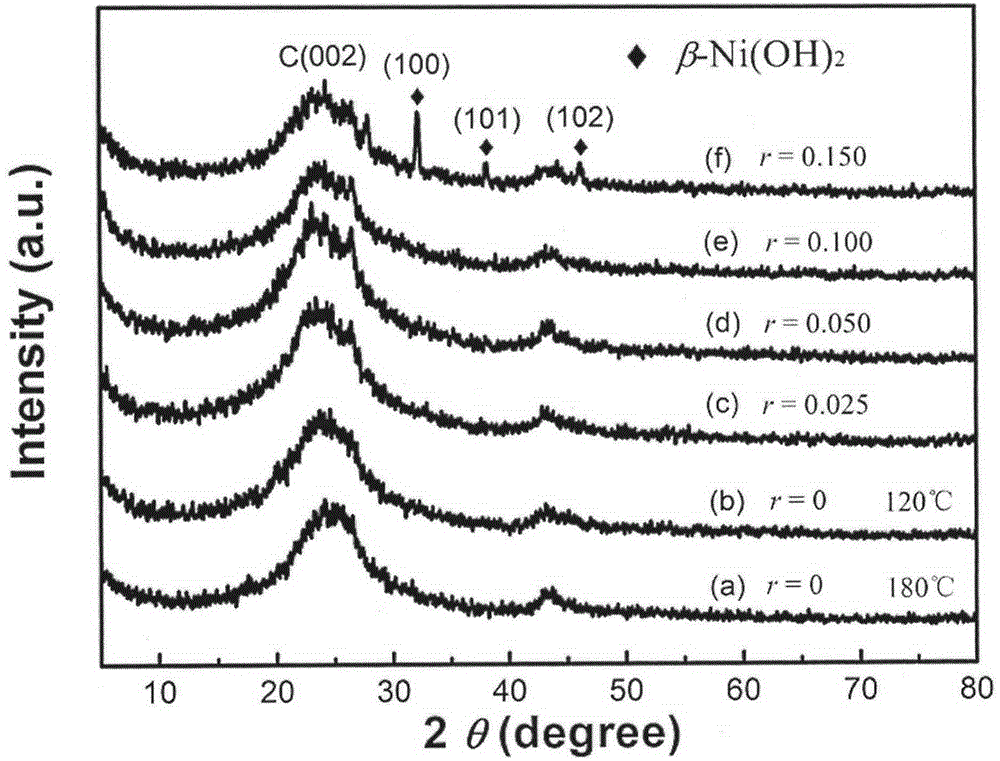

[0029] Three-dimensional net-like GO nanostructure: Graphite oxide powder was prepared from graphite powder purchased on the market using the improved Hummer method; 30.2 mg of graphite oxide powder was added to deionized water, and ultrasonically dispersed to obtain a concentration of 1.0 mg / mL under the action of continuous ultrasound, add 20mg polyvinyl alcohol, and stir the mixed solution with ultrasonic and magnetic force for 1 hour respectively; 12h; After the reaction, it was naturally cooled to room temperature, and the product was repeatedly centrifuged and washed, and finally dried in a freeze dryer for 20h.

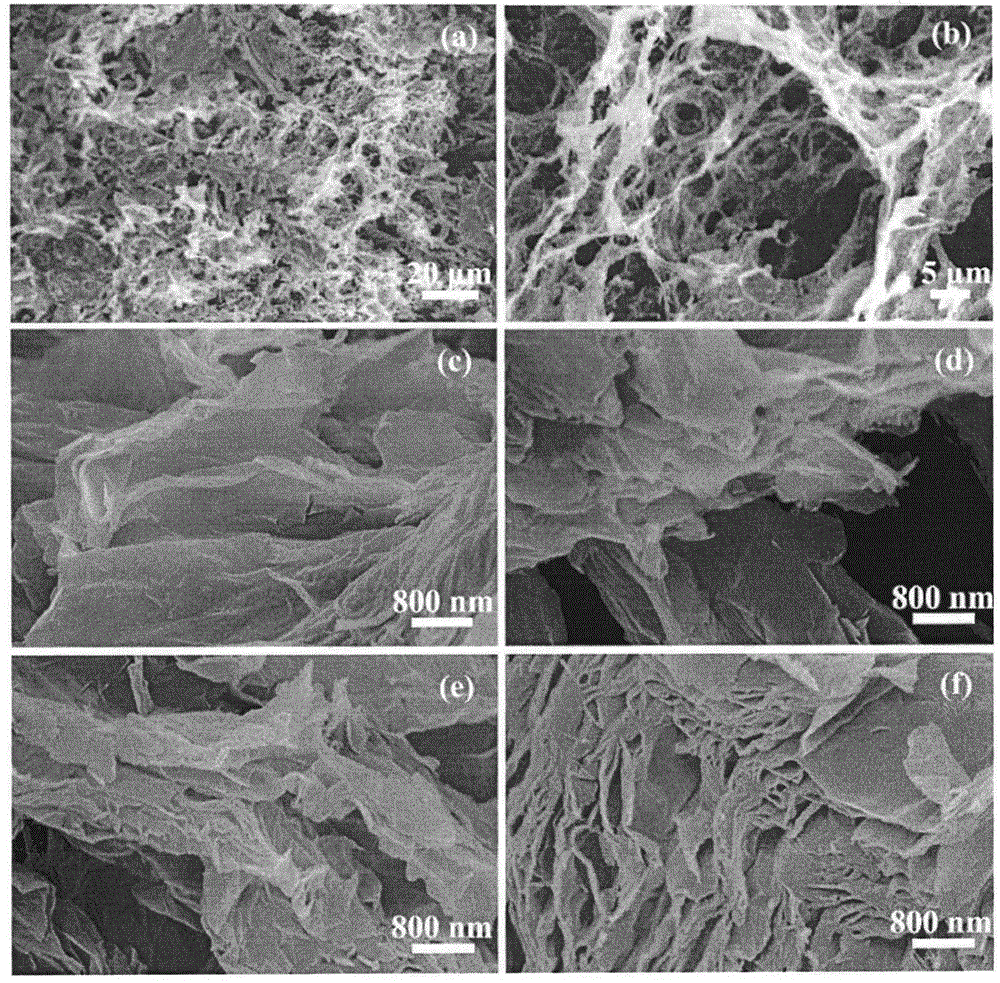

[0030] figure 1 a-b are representative SEM images of the product obtained in Example 1. It can be seen that the product has an obvious three-dimensional network structure, which is formed by the interweaving of very thin nanosheets in three-dimensional space, forming many holes. Since polyvinyl alcohol can infiltrate the pores of the three-dimensional network...

Embodiment 2

[0032] Reaction temperature is 120 ℃, and other conditions are with example 1.

[0033] The product of Example 2 is an aggregate with irregular shape and large size. This is due to the fact that at lower temperatures, the attractive force generated by the π-π interaction is much greater than the repulsive force of the random arrangement, leading to the formation of products composed of graphene oxide nanosheets that are tightly packed. This indicates that the three-dimensional network nanostructure of graphene oxide cannot be obtained when the temperature is lower than 120 °C.

Embodiment 3

[0035] Ni 2+ When the molar ratio (r) to graphite oxide powder was 0.025, the reaction temperature was 120° C., and other conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com