Temperature-sensitive dispersing agent, temperature-sensitive suspending liquid and application of temperature-sensitive dispersing agent and temperature-sensitive suspending liquid

A dispersant, temperature-sensitive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

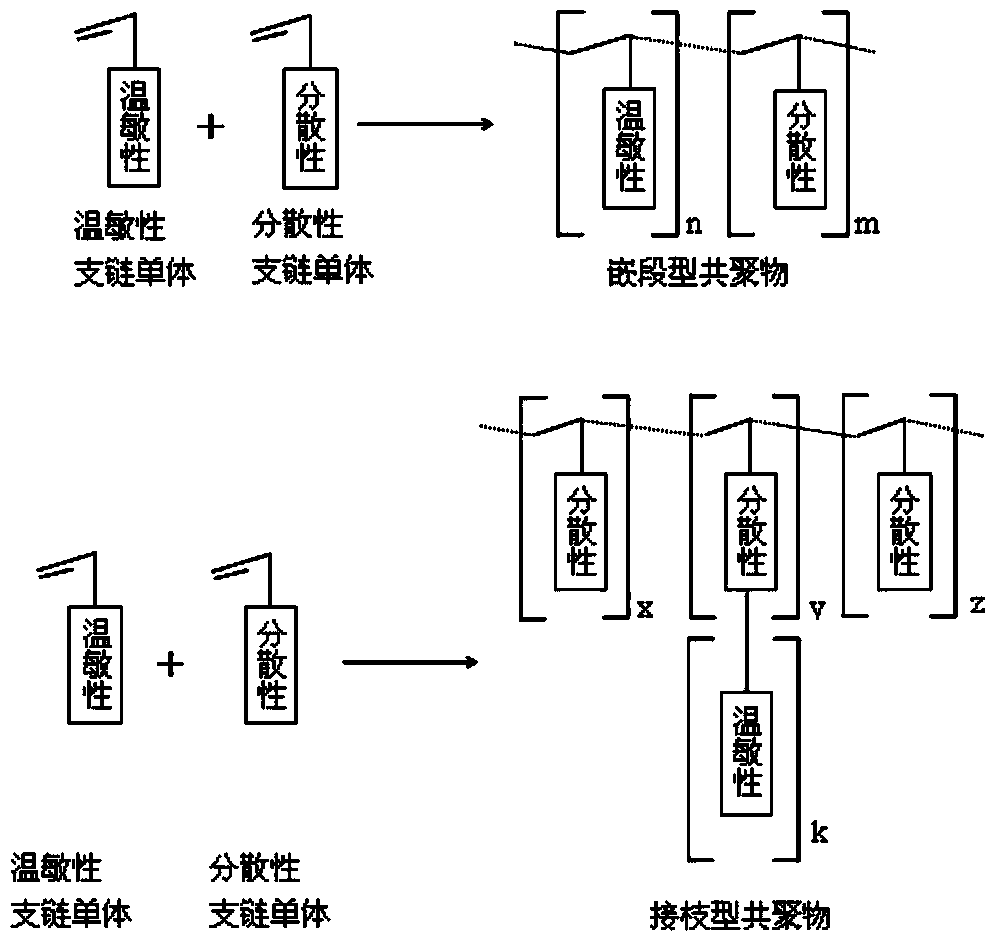

[0032] Preparation of Si by Graft Copolymer Type Temperature Sensitive Dispersant Polyethyleneimine-Polyethylene Oxide Monomethyl Ether (PEI-g-PEO) 3 N 4 Thermosensitive suspension.

[0033] First, synthesis of temperature-sensitive polyoxyethylene monomethyl ether macromonomer (PEO macromonomer): adding polyoxyethylene monomethyl ether (2.25 g, 4.5 mmol) with a molecular weight of 500 and triethylamine ( 2.27g, 3.15mL), slowly added dropwise acryloyl chloride (2.03g, 1.84mL) under nitrogen protection at 0°C; after 30min, the temperature was raised to room temperature, and the reaction was continued for 24h. After the reaction, the precipitate produced by the reaction was filtered off; the product in the filtrate washed out with petroleum ether was the temperature-sensitive polyoxyethylene monomethyl ether macromonomer (PEO macromonomer). Then, synthesize the thermosensitive dispersant: the PEO macromonomer of different ratios and polyethyleneimine (PEI, molecular weight is ...

Embodiment 7~10

[0038] Preparation of Si by Graft Copolymer Type Temperature Sensitive Dispersant Polyethyleneimine-Polyethylene Oxide Monomethyl Ether (PEI-g-PEO) 3 N 4 ceramics.

[0039] The temperature-sensitive dispersant PEI-g-PEO and ceramic powder in the temperature-sensitive suspension in Example 1 are adjusted, and the sintering aid Y is added 2 o 3 with La 2 o 3 (see Table 2 for the specific addition amount), then continue ball milling for 2 hours, and then pour into the mold after defoaming; the mold is placed in a blast drying oven and kept at 60°C for 2 hours to make the temperature-sensitive dispersant generate affinity - Hydrophobic transition, the rheological properties of the suspension, such as the increase in the storage elastic modulus, solidification occurs, and then the upper layer of water is poured out, and then placed at 80°C for 4 hours to dry the green body, and then the green body is removed from the mold Then put the green body under the condition of 120°C fo...

Embodiment 11

[0044] Preparation of ZrO by Block Copolymer Type Thermosensitive Dispersant Polyacrylic Acid-Polyoxyethylene Monomethyl Ether (PAA-b-PEO) 2 Thermosensitive suspension.

[0045] Polyoxyethylene monomethyl ether MPEO (0.2g, 1mmol) and polyacrylic acid PAA (4.27g, 4mmol) were dissolved in 20mL tetrahydrofuran, and after stirring and dispersing evenly, N,N'-dicyclohexylcarbodiimide DCC ( 1.03g, 5mmol) and an appropriate amount of dimethylaminopyridine DMAP, continue to react at 50°C for 16 hours, after the reaction is completed, remove the insoluble matter by filtration, add the filtrate dropwise to 300mL of chloroform, and wash the precipitate obtained with ethyl acetate solvent for 3 After the second time, it was vacuum dried for 24 hours to obtain the temperature-sensitive dispersant PAA-b-PEO.

[0046] The thermosensitive dispersant PAA-b-PEO (4g) and ZrO 2 The powder (160 g) was added into 10 mL of deionized water and ball-milled together to prepare a suspension. Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com