Single-component heavy-duty corrosion-resistant polyurea for buried pipeline and preparation method of polyurea

A buried pipeline, one-component technology, applied in the field of polyurea, can solve the problems of inaccurate measurement of two-component systems, short gel time, limited use, etc., and achieves extended operation time, simple construction and improved work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

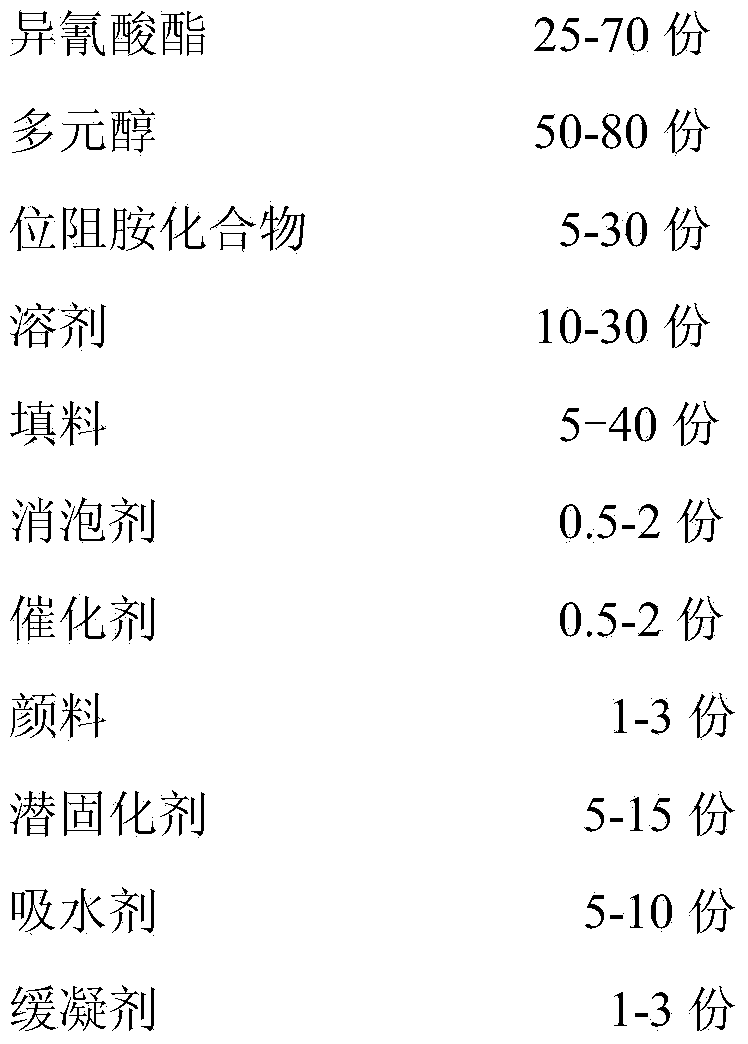

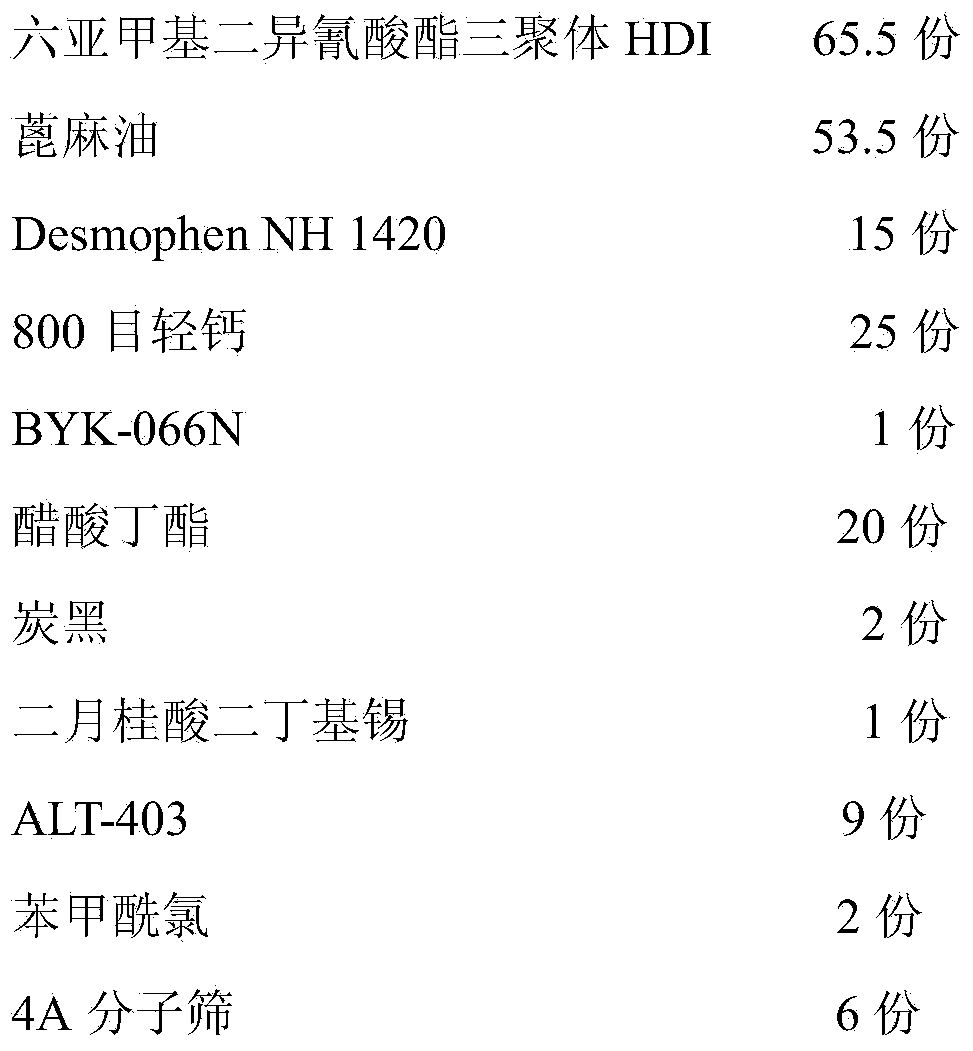

[0042] This embodiment discloses a single-component heavy-duty anti-corrosion polyurea for buried pipelines, which includes the following components by weight:

[0043]

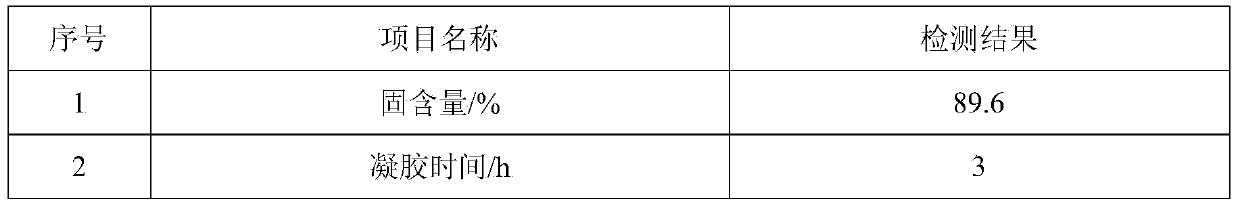

[0044] The preparation method of single-component heavy-duty anti-corrosion polyurea for buried pipelines provided in this embodiment:

[0045] ① Add castor oil, Desmophen NH1420, 800 mesh light calcium, and carbon black into the container according to the above weight parts, stir the liquid material at a low speed for 5 minutes, heat it to 110~120°C, turn on the vacuum pump, and the vacuum degree is -0.1~- 0.08MPa, vacuum dehydration for 2h, remove a small amount of water contained in the raw material, check that the moisture content is below 3 / 10,000, and cool to a liquid temperature of about 25 °C.

[0046] ②Add butyl acetate and HDI into the above container by weight, heat up to 50°C, stir and react for 1 hour, slowly heat up to 110-120°C after the reaction exotherm ends, keep the reaction for 8h, take...

Embodiment 2

[0053] This embodiment discloses a single-component heavy-duty anti-corrosion polyurea for buried pipelines, which includes the following components by weight:

[0054]

[0055]

[0056] The preparation method of single-component heavy-duty anti-corrosion polyurea for buried pipelines provided in this embodiment:

[0057] ①Add polyoxypropylene ether polyol PPG-1000, Desmophen NH1420, 800-mesh light calcium, 800-mesh talcum powder, and carbon black into the container according to the above weight parts, stir the liquid material at low speed for 5 minutes, and heat it to 110-120 ℃, turn on the vacuum pump, the vacuum degree is -0.1~-0.08MPa, vacuum dehydration for 2h, remove a small amount of water contained in the raw material, detect the moisture content below 3 / 10,000, and cool to the liquid temperature of about 25℃.

[0058] ②Add butyl acetate and MDI into the above container by weight, heat up to 50°C, stir and react for 1 hour, slowly heat up to 80-90°C after the rea...

Embodiment 3

[0065] This embodiment discloses a single-component heavy-duty anti-corrosion polyurea for buried pipelines, which includes the following components by weight:

[0066]

[0067] The preparation method of single-component heavy-duty anti-corrosion polyurea for buried pipelines provided in this embodiment:

[0068] ①Add polyoxypropylene ether polyol PPG-1000, Desmophen NH1420, 800 mesh talc and carbon black into the container according to the above weight parts, stir the liquid material at low speed for 5 minutes, heat it to 110~120℃, turn on the vacuum pump, The vacuum degree is -0.1~-0.08MPa, vacuum dehydration for 2h, remove a small amount of water contained in the raw material, detect the moisture content below 3 / 10,000, and cool to the liquid material temperature of about 25 ℃.

[0069] ②Add butyl acetate and HMDI into the container by weight, heat up to 50°C, stir and react for 0.5 hours, after the reaction exotherm is over, add MDI, slowly heat up to 80~90°C, keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com