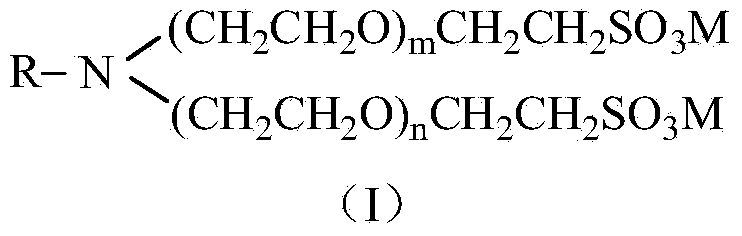

Fatty amine polyoxyethylene ether diethyl disulfonate surfactant and preparation method thereof

A technology of aliphatic amine polyoxyethylene ether and surfactant, which is applied in the direction of sulfonate preparation, chemical instruments and methods, and drilling compositions, etc., and can solve problems such as high equipment requirements, harsh synthesis conditions, and strong corrosion , to achieve the effect of reducing the interfacial tension of oil and water, easy biodegradation, and good surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

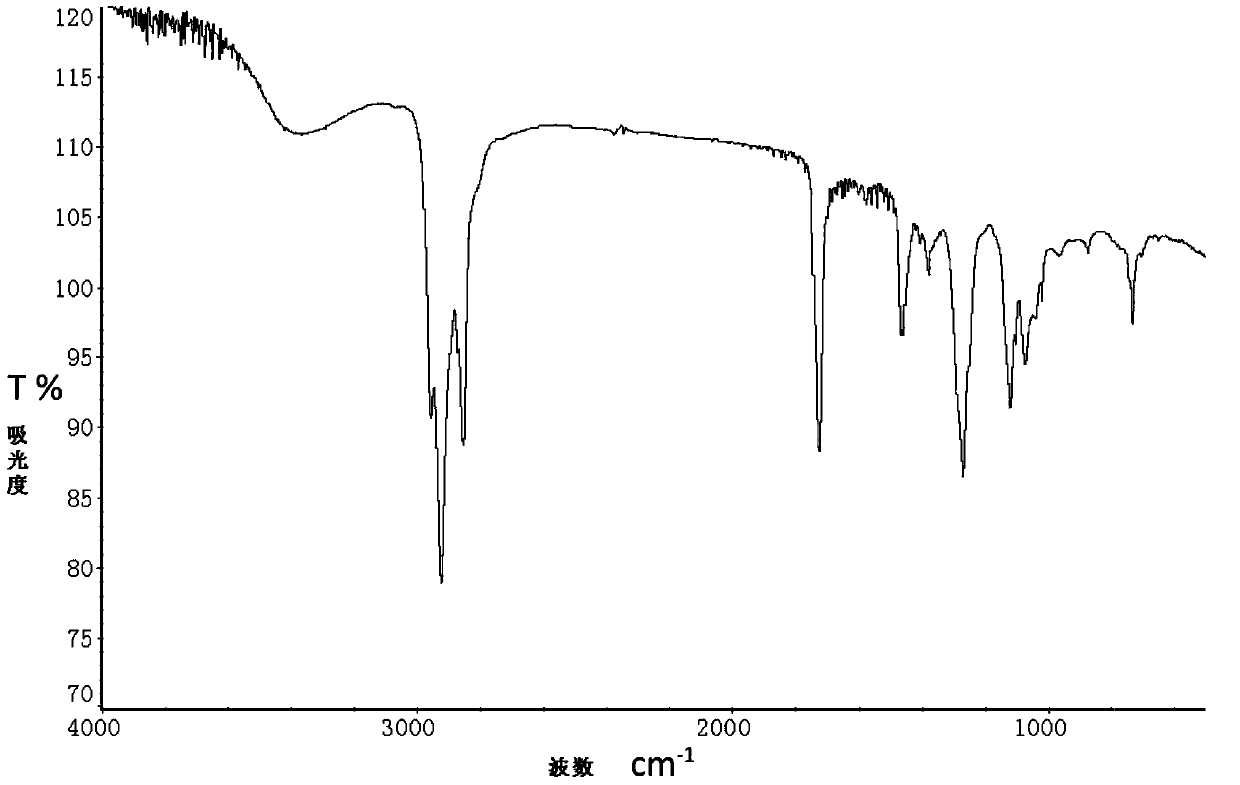

[0030] Example 1 Preparation of Laurylamine Polyoxyethylene Ether (2) Sodium Diethylbissulfonate

[0031] Add 5.4 g of laurylamine polyoxyethylene ether (2) and 2.4 g of solid sodium hydroxide into a three-necked flask, pass nitrogen to deoxygenate and dehydrate, stir and react at 100°C for 0.5 hours, cool down to room temperature, and then add 20 mL of toluene as a solvent, Add 10.9 g of sodium chloroethylsulfonate, raise the temperature to 85°C and react for 8 hours to obtain a crude product, remove the toluene by rotary evaporation, add hot absolute ethanol to dissolve the product, remove excess alkali, sodium chloroethylsulfonate and the generated product by suction filtration sodium chloride, the filtrate was concentrated, recrystallized with absolute ethanol, and the obtained solid was dried to obtain the target product in the form of white powder with a yield of 66%.

[0032] The final product obtained in this embodiment has an equilibrium interfacial tension between th...

Embodiment 2

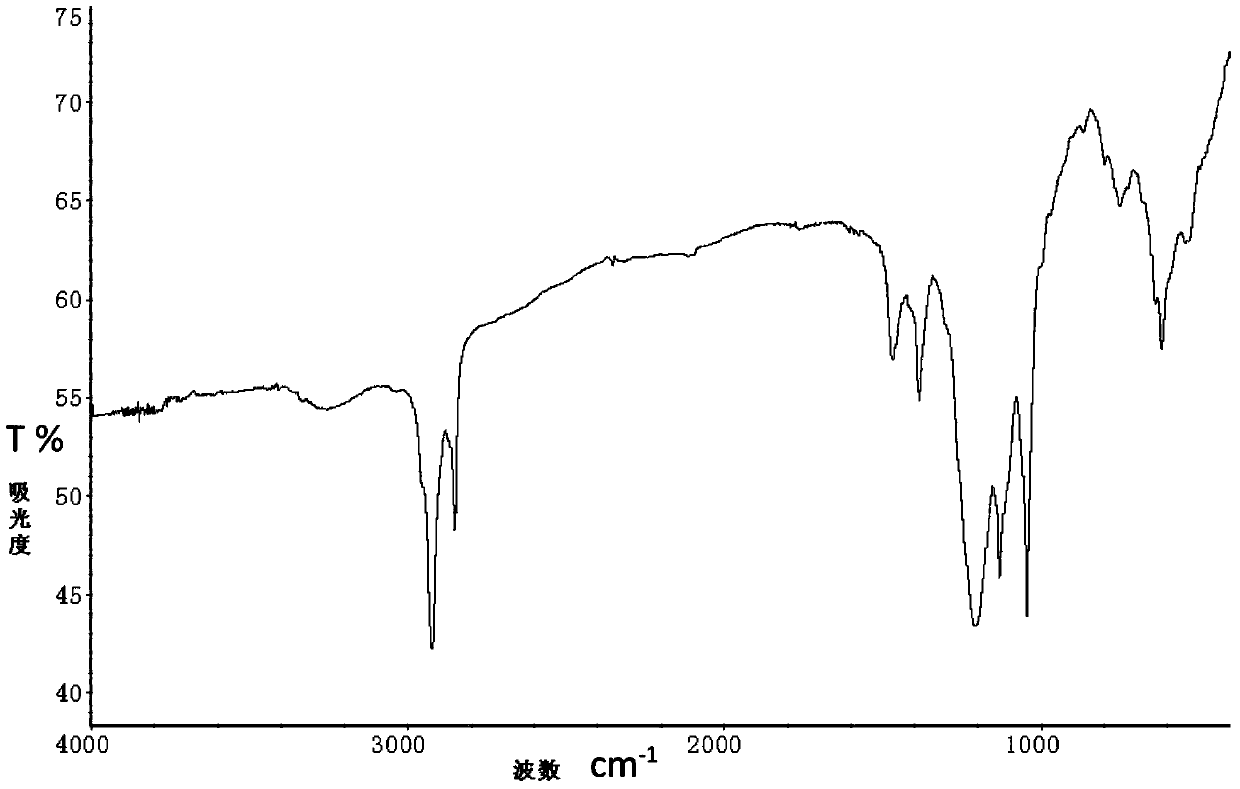

[0033] Example 2 Preparation of Sodium Laurylamine Polyoxyethylene Ether (5) Diethylbissulfonate

[0034] Add 8.7 g of laurylamine polyoxyethylene ether (5) and 3.0 g of solid potassium hydroxide into a three-necked flask, pass nitrogen to deoxygenate and dehydrate, stir and react at 100°C for 1.5 hours, cool down to room temperature, and then add 20 mL of toluene as a solvent, Add 9.9 g of sodium chloroethylsulfonate, raise the temperature to 95°C and react for 10 hours to obtain a crude product, remove the toluene by rotary evaporation, add hot absolute ethanol to dissolve the product, remove excess alkali, sodium chloroethylsulfonate and the generated product by suction filtration sodium chloride, the filtrate was concentrated, recrystallized with absolute ethanol, and the obtained solid was dried to obtain the target product in white powder form with a yield of 75%.

[0035] The final product obtained in this embodiment has an equilibrium interfacial tension between the de...

Embodiment 3

[0036] Example 3 Preparation of stearylamine polyoxyethylene ether (2) sodium diethylbissulfonate

[0037] Add 9.6g of stearylamine polyoxyethylene ether (2) and 2.7g of solid sodium hydroxide into a three-necked flask, pass nitrogen to remove oxygen and dehydrate, stir and react at 100°C for 1 hour, cool down to room temperature, and then add 20mL of toluene as solvent , add 12.4 g of sodium chloroethylsulfonate, heat up to 95°C and react for 12 hours to obtain a crude product, remove toluene by rotary evaporation, add hot absolute ethanol to dissolve the product, remove excess alkali and sodium chloroethylsulfonate and form sodium chloride, the filtrate was concentrated, recrystallized with absolute ethanol, and the obtained solid was dried to obtain the white powdery target product with a yield of 71%.

[0038] The interfacial tension between the final product obtained in this example and the dehydrated and degassed crude oil in a block in the tower within the range of 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com