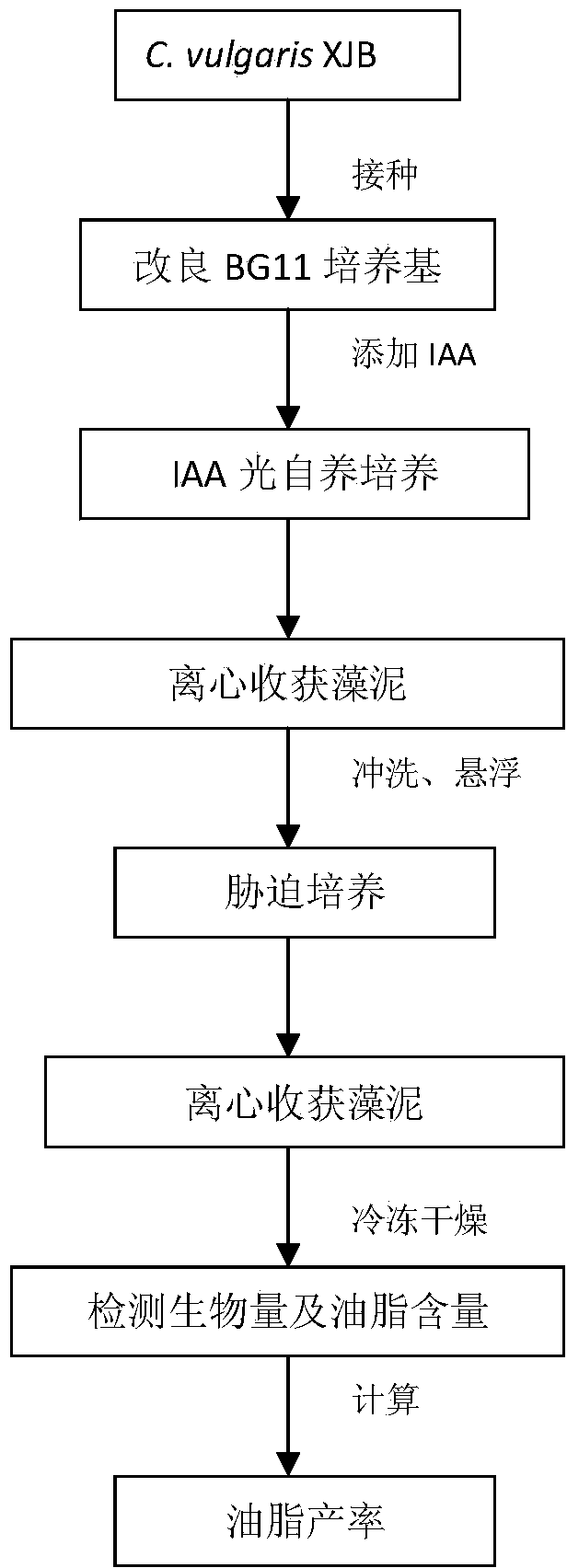

Method for improving oil yield of microalgae

A microalgae oil and oil production rate technology, applied in the field of bioengineering, can solve the problems of easy bacterial contamination, high production cost, and high equipment requirements, and achieve the effects of simultaneously increasing biomass and oil content, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take an appropriate amount of C.vulgaris XJB algae liquid and inoculate it into a 1L Erlenmeyer flask containing 600mL of medium. The inoculum amount of the algae liquid is 10%, and the medium is: NaNO 3 0.83g / L,K 2 HPO4·3H 2 O 0.09g / L, MgSO 4 ·7H 2 O 0.12g / L, CaCl 2 27.2mg / L, Citric-acid 6.6mg / L, Fe(NH 4 ) 3 (C 6 h 5 o 7 ) 2 6.0mg / L, Na 2 EDTA·2H 2 O 1.1mg / L, NaCO 3 20mg / L, A5 trace element mixture 0.2mL / L, NaHCO 3 2.34g / L. Add 0.08mg / L triindoleacetic acid IAA to the basal medium, culture in photoautotroph at temperature 24±2°C, light intensity 6000±200lux, photoperiod 24:0 (L:D), and shake the flask three times a day.

[0023] According to the growth curve drawn by the number of cells regularly detected every day, the algae liquid was centrifuged at 4000r / min for 5 minutes in the stationary phase to obtain concentrated algae, and washed 5 times with distilled water, and all suspended in NaNO after washing away inorganic salt ions 3 Concentration i...

Embodiment 2

[0028] The photoautotrophic culture process of Chlorella and IAA used in this embodiment is the same as that in Embodiment 1.

[0029] Among them, the algae sludge obtained after IAA treatment is suspended under stress conditions, that is, NaNO 3 Concentration is 0.20g / L, other nutrient components are in the stress medium of the culture medium described in Example 1, under the conditions of 24 ± 2 ℃ under the light intensity is 8000lux, photoperiod is 24:0 (L:D) , stress culture for 2 days.

[0030] After stress cultivation to the stable stage, the detection and calculation of biomass, oil content, and oil yield are the same as in Example 1. After the above-mentioned IAA photoautotrophy---light and nitrogen stress culture, the oil yield of C.vulgaris XJB can reach 57.9 mg / L·d, which was increased by 2.8 times compared with the condition of only IAA culture, and increased by 6.5 times compared with the condition of no IAA or stress culture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com