GdPO4*H2O nanometer bundle composite material and preparation method thereof

A composite material and nanorod technology, applied in the field of GdPO4·H2O nanobeam composite material and its preparation, can solve the problems of long cycle, inability to guarantee materials, degradation, etc., to achieve controllable degradation, realize tracer monitoring, and accelerate degradation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of composite material, comprising: biodegradable material and GdPO 4 ·H 2 O mixed to obtain a composite material.

[0032] According to the present invention, the present invention combines biodegradable material and GdPO 4 ·H 2 O mixed to obtain a composite material, according to the present invention, the biodegradable material and the GdPO 4 ·H 2 The mass ratio of O is preferably 1000 mg: (0.005-60) mg, more preferably 1000 mg: (2.5-35) mg, most preferably 1000 mg: (8-30) mg. The biodegradable material is preferably polylactic acid, polyglycolic acid, polycaprolactone, polyhydroxybutyrate, polyanhydride or polylactic acid, polyglycolic acid, polycaprolactone, polyhydroxybutyrate and polyanhydride. Two or more copolymers, more preferably polylactic acid, polyglycolic acid, polycaprolactone, polyhydroxybutyrate or polyanhydride; the GdPO 4 ·H 2 O is preferably staggered nanorods, the length of the nanorods...

Embodiment 1

[0041] Preparation of GdPO 4 ·H 2 O and GdPO 4 nanobeam

[0042] 1mLGd(NO 3 ) 3 (1mM) aqueous solution is added to 25mL ethylene glycol solution, weigh 2.0g PVP and add it to the above solution, weigh NH 4 h 2 PO 4 Dissolve 0.25g and 0.5g of urea in 5mL of aqueous solution, then add to the above solution, weigh 3.0g of glycine and add to the above solution, stir for 30min; The precipitate was washed by centrifugation and dried to obtain GdPO 4 ·H 2 O nanobeams.

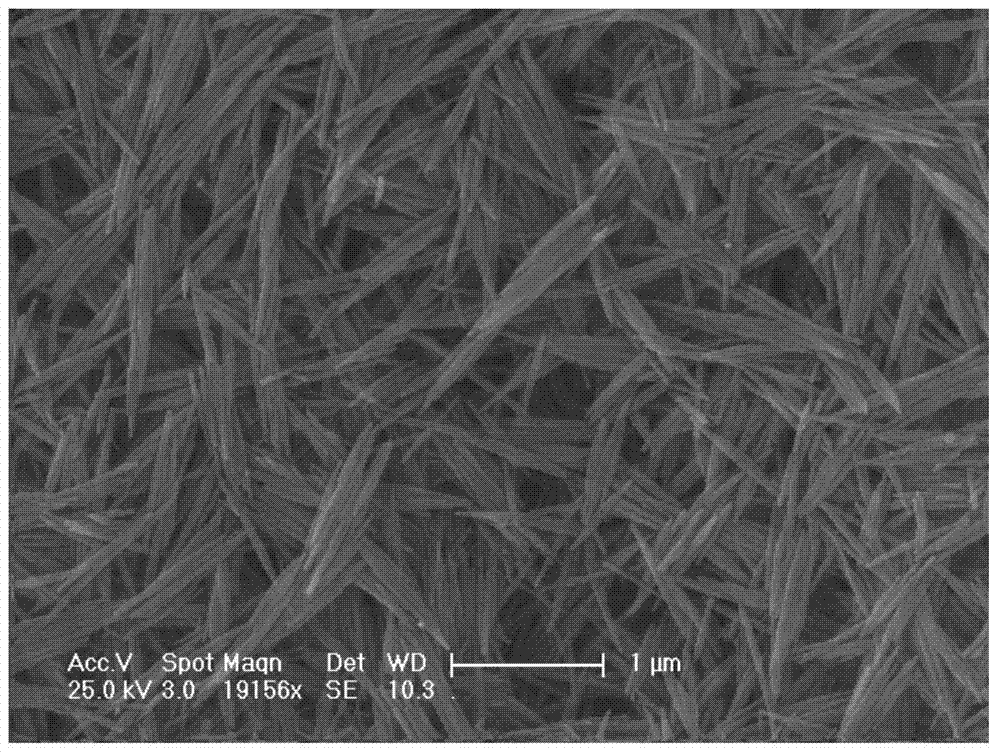

[0043] GdPO prepared by embodiment 1 by scanning electron microscope 4 ·H 2 O for detection, see the results figure 1 , figure 1 GdPO provided for the embodiment of the present invention 4 ·H 2 SEM image of O.

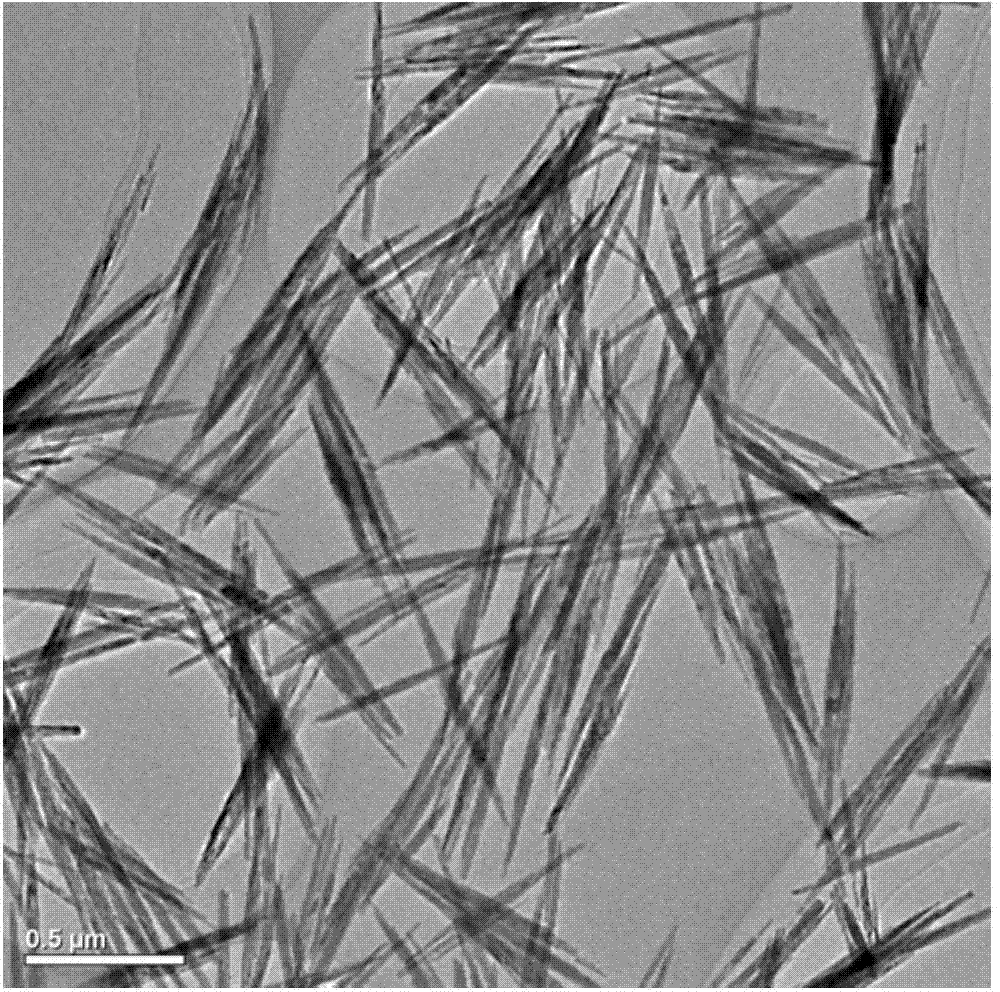

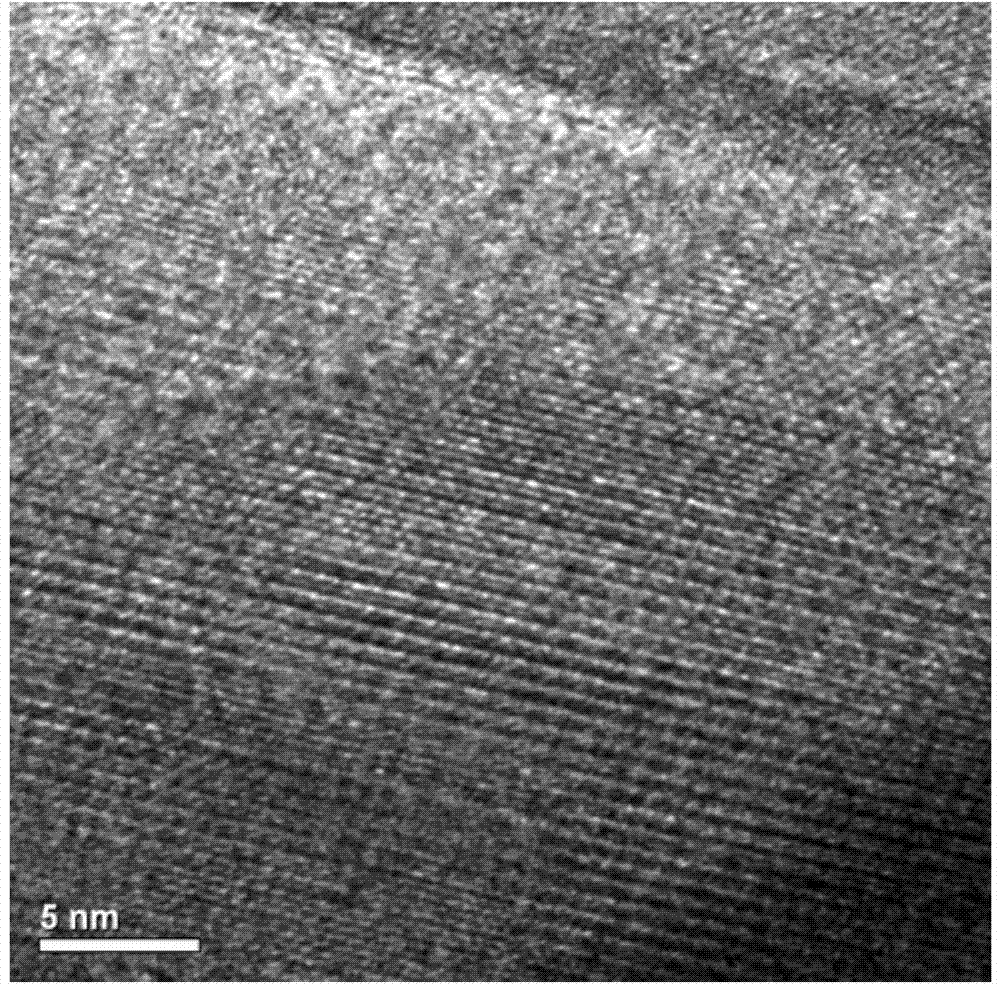

[0044] GdPO prepared by embodiment 1 by transmission electron microscope 4 ·H 2 O for detection, see the results Figure 2~4 , figure 2 GdPO provided for the embodiment of the present invention 4 ·H 2 O beam structure diagram obtained by transmission electron microscopy, image 3 GdPO p...

Embodiment 2

[0046] The GdPO prepared by 3mg embodiment 1 4 ·H 2 O was added to 6mL NMP solvent, and ultrasonically mixed; then HA60mg was added, and ultrasonically mixed; then 1.2g of PLGA was weighed and added to the above solution, and stirred overnight until PLGA was evenly dissolved; Or pour the mixed solution into a centrifuge tube to solidify, then put it into an aqueous solution, and obtain a membrane composite material or a scaffold composite material after the solvent replacement is complete.

[0047] The film composite material prepared in embodiment 2 is carried out magnetocaloric degradation experiment, and its result sees Figure 5 , Figure 5 The weight loss rate of the composite material provided for the embodiment of the present invention under the condition of adding a magnetic field and not adding a magnetic field, it can be seen from the figure that the degradation rate of the composite material is different under the condition of adding a magnetic field and not addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com