Preparation method of polyurethane epoxy resin acrylate ternary polymerization resin nano aqueous dispersion

A technology of acrylate ternary copolymerization resin and epoxy resin, which is applied in the chemical industry, can solve the problems of no chemical connection, complex process, and low degree, and achieve good compatibility between components, rich functional groups, and high conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

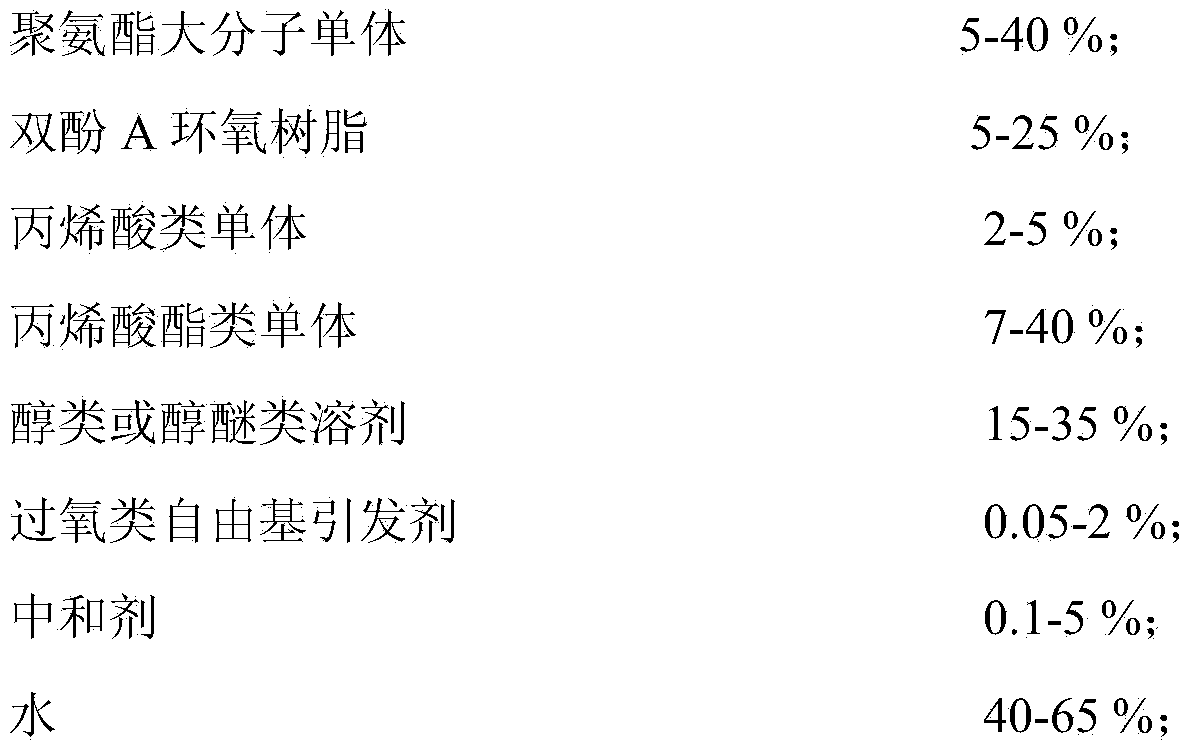

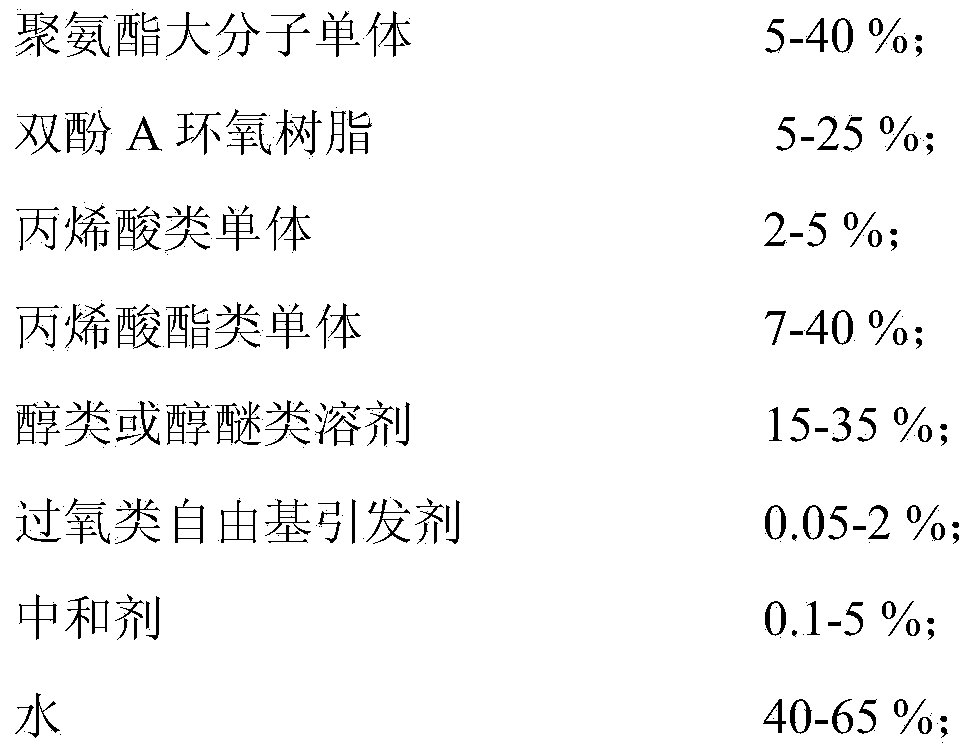

Method used

Image

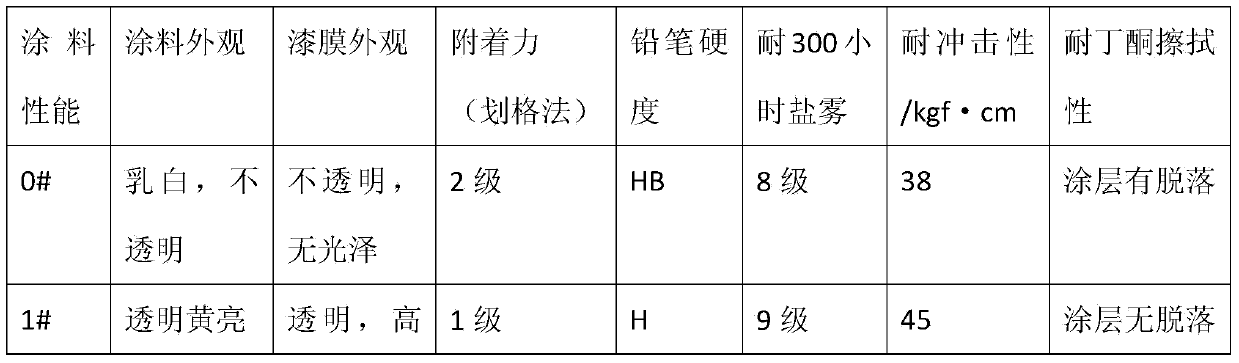

Examples

Embodiment 1

[0041] Add 90 g of polyester diol (polybutylene adipate diol, PBA) with a molecular weight of 2000 into a reaction kettle equipped with a stirrer and a reflux condenser, vacuum dehydration for 1 hour, and then add dimethylol Propionic acid 3g, replace nitrogen for 10 minutes, heat up to 75°C, add toluene diisocyanate 12g, catalyst dibutyltin dilaurate 0.1g, react for 3 hours, then cool down to 65°C, add 1.2g hydroxyethyl acrylate to react for 1 hour , to prepare polyurethane macromonomer.

[0042] Add n-butanol 100g, propylene glycol butyl ether 100g and epoxy resin E4466g in the flask again, replace nitrogen for 10 minutes, heat up while stirring, make material temperature reach 100 ℃. At the same time, mix and dissolve 30g of methacrylic acid, 30g of hydroxyethyl methacrylate, 50g of ethyl acrylate, 20g of butyl acrylate and 7g of benzoyl peroxide, and gradually drop them into the reaction kettle as a mixed dropping solution, and drop The time is 3.5 hours, and then keep wa...

Embodiment 2

[0044] Add 90 g of polyether diol (polyoxypropylene diol, N220) with a molecular weight of 2000 into a reaction kettle equipped with a stirrer and a reflux condenser, vacuum dehydration for 1 hour, then add 3 g of dimethylol propionic acid to replace Nitrogen for 10 minutes, heat up to 80°C, add 15.3g of isophorone diisocyanate, 0.1g of catalyst dibutyltin dilaurate, react for 3 hours, then cool down to 65°C, add 1.2g of hydroxyethyl acrylate to react for 1 hour, A polyurethane macromonomer is prepared.

[0045] Add n-butanol 100g, propylene glycol butyl ether 100g and epoxy resin E12 62g in the flask again, replace nitrogen for 10 minutes, heat up while stirring, make material temperature reach 115 ℃. At the same time, mix and dissolve 35g of methacrylic acid, 45g of hydroxyethyl methacrylate, 20g of ethyl acrylate, 30g of butyl acrylate and 10g of benzoyl peroxide, and gradually drop them into the reaction kettle as a mixed dropping solution, and dropwise add The time is 3.5 ...

Embodiment 3

[0047] Add 100 g of polyether diol (polyoxypropylene diol, N210) with a molecular weight of 1000 into a reaction kettle equipped with a stirrer and a reflux condenser, vacuum dehydration for 1 hour, then add 4 g of dimethylol propionic acid to replace Nitrogen for 10 minutes, heat up to 75°C, add 40g of isophorone diisocyanate, 0.15g of dibutyltin dilaurate as a catalyst, react for 3 hours, then cool down to 65°C and add 6g of hydroxypropyl acrylate to react for 1 hour to prepare Polyurethane macromonomer.

[0048] Add n-butanol 100g, propylene glycol butyl ether 100g and epoxy resin E44 30g in the flask again, replace nitrogen for 10 minutes, heat up while stirring, make the material temperature reach 115 ℃. Simultaneously, 15g of acrylic acid, 25g of hydroxyethyl acrylate, 40g of methyl methacrylate, 40g of butyl acrylate and 10g of benzoyl peroxide are mixed and dissolved, and as a mixed dripping solution, they are gradually dropped into the reactor, and the dropping time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com