Gradient type macromolecule-based neutron absorption grid tray material and preparation method thereof

A polymer-based, neutron absorber technology, applied in chemical instruments and methods, layered products, lamination, etc., can solve the problems of insufficient neutron absorber function and narrow neutron energy spectrum absorption range, etc., to achieve Improving mechanical properties, ensuring safety, and ensuring the effect of absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

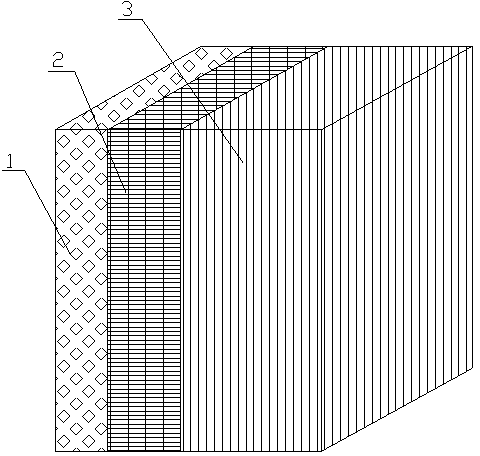

Image

Examples

Embodiment 1

[0032] The preparation method of gradient polymer-based neutron-absorbing grid material comprises the following steps:

[0033] a. First, heat the polyimide resin at 80°C to make the resin have good fluidity. By adding the organic solvent acetone into the polyimide resin and fully stirring it at 60°C, according to the thermosetting The viscosity of the polymer resin is large, and the thermosetting polymer resin is diluted (if the thermosetting polymer resin used has a low viscosity, there is no need to dilute it with a solvent), and the diluted polyimide glue is obtained for use;

[0034] b. Divide the glue solution into three parts, and then add lithium fluoride, samarium oxide and gadolinium oxide respectively to the diluted thermosetting glue solution to prepare functional glue solutions containing absorbent fillers with different neutron absorbers;

[0035] c. Irradiate the carbon fiber used under the irradiation dose of 120kGy to improve the bonding strength between the f...

Embodiment 2

[0039] The preparation method of gradient polymer-based neutron-absorbing grid material comprises the following steps:

[0040] a. First mix the bisphenol-A epoxy resin with the anhydride curing agent, the ratio is 1:1, so that the resin has good fluidity, then pour the imidazole accelerator, and stir fully to obtain a uniformly mixed epoxy resin Glue;

[0041] b. Divide the glue solution into three parts, and then add lithium fluoride, samarium oxide and gadolinium oxide respectively to the epoxy resin glue solution to prepare functional glue solutions containing absorbent fillers with different neutron absorbers;

[0042] c. Use a silane coupling agent to couple the surface of the glass fiber to improve the bonding strength between the fiber surface and the resin matrix;

[0043] d. Cut the glass fiber after coupling treatment into required size and impregnate the mixed glue, arrange the materials in the order of lithium fluoride layer, samarium oxide layer and gadolinium o...

Embodiment 3

[0046] The preparation method of gradient polymer-based neutron-absorbing grid material comprises the following steps:

[0047] a. First, heat the polyimide resin at 80-90°C to make the resin have good fluidity. Add organic solvent acetone to the polyimide resin, and fully Stir, and dilute the thermosetting polymer resin according to the viscosity of the thermosetting polymer resin to obtain the diluted polyimide glue for later use;

[0048] b. Divide the glue solution into three parts, and then add lithium hydride, cadmium oxide and gadolinium oxide respectively to the diluted thermosetting glue solution to prepare functional glue solutions containing absorbent fillers with different neutron absorbers;

[0049]c. Irradiate the continuous glass fiber used at a radiation dose of 120kGy to improve the bonding strength between the fiber surface and the resin matrix;

[0050] d. After impregnating the treated reinforcing fibers with different absorber glues, arrange the materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com