Super-hydrophobic/super-oleophylic polyurethane oil-absorption sponge and preparation method thereof

A super-hydrophobic, polyurethane technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex migration and transformation, and achieve the effect of simple preparation method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

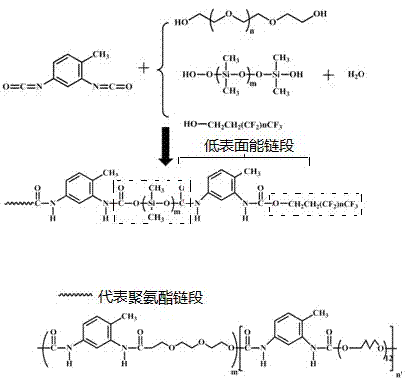

Method used

Image

Examples

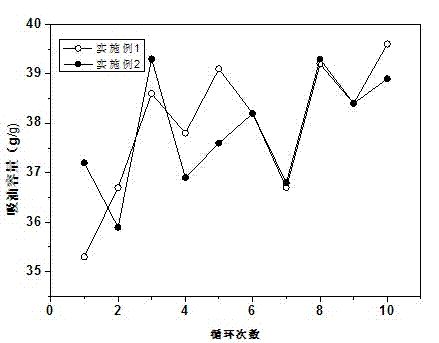

Embodiment 1

[0032] Embodiment 1 Preparation of oil-absorbing sponge of the present invention

[0033] The weight ratio of each component: 20 parts of diphenylmethane diisocyanate MDI (BASF M20S), 10 parts of polyether polyol soft foam polyether polyol polymer polyether polyol POP-3628, 10 parts of hydroxyl silicone oil, 10 parts Perfluorooctyl ethyl alcohol, 1 part of water, 2 parts of liquefied petroleum gas, 0.1 part of stannous octoate, 0.5 part of pentaerythritol, 2 parts of melamine phosphate MELAPUR 200, 2 parts of antioxidant 1010 (tetra[β-(3,5 - di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol), 2 parts of foam stabilizer (BK, SILBYK9230).

[0034]Put the raw materials into the stirring tank according to the above formula, control the temperature in the stirring tank at 18-26°C, and stir at a high speed of 5000r / min for 30 minutes. The uniformly stirred raw materials are evenly sprayed into the foaming chamber through the metering pump for foaming, and the foaming tim...

Embodiment 2

[0037] Embodiment 2 Preparation of oil-absorbing sponge of the present invention

[0038] The weight ratio of each component: 50 parts of diphenylmethane diisocyanate (Bayer, 2460M), 40 parts of combined polyether polyol 3050 (3050 is the industrial label, polyether polyol has many types according to molecular weight and molecular structure difference) , this is a specific label), 5 parts of hydroxyl silicone oil, 15 parts of heptadecylfluorodecyltrimethoxysilane, 4 parts of water, 5 parts of petroleum ether, 1.5 parts of ethyldiamine, 3 parts of trimethylolpropane acrylate , 10 parts of resorcinol bis(diphenyl phosphate), 5 parts of antioxidant 168 (tris(2,4-di-tert-butylphenyl) phosphite), 5 parts of foam stabilizer (Side, silicone oil SD -102).

[0039] Put the raw materials into the stirring tank according to the above formula, control the temperature in the stirring tank at 18-26°C, and stir at a high speed of 6000r / min for 30 minutes. The uniformly stirred raw materi...

Embodiment 3

[0041] Embodiment 3 Preparation of oil-absorbing sponge of the present invention

[0042] The weight ratio of each component: 30 parts of diphenylmethane diisocyanate (Huntsman 5005), 25 parts of polyether polyol polyether (LEP-330N), 5 parts of hydroxyl silicone oil, 10 parts of 1H, 1H, 2H, 2H -Perfluorodecyltriethoxysilane, 2.5 parts water, 4.5 parts dichlorofluoroethane, 1 part stannous octoate, 2.5 parts trimethylolpropane methacrylate, 8 parts flame retardant melamine phosphate MELAPUR MP, 1 part antioxidant (antioxidant 168), 2 parts water-soluble polyether siloxane (foam stabilizer SILBYK-9230).

[0043] Put the raw materials into the stirring tank according to the above formula, control the temperature in the stirring tank at 18-26°C, and stir at a high speed of 5000r / min for 30 minutes. The uniformly stirred raw materials are evenly sprayed into the foaming chamber by a metering pump for foaming, and the foaming time is controlled at 1 minute. The foamed sponge is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com